3202

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

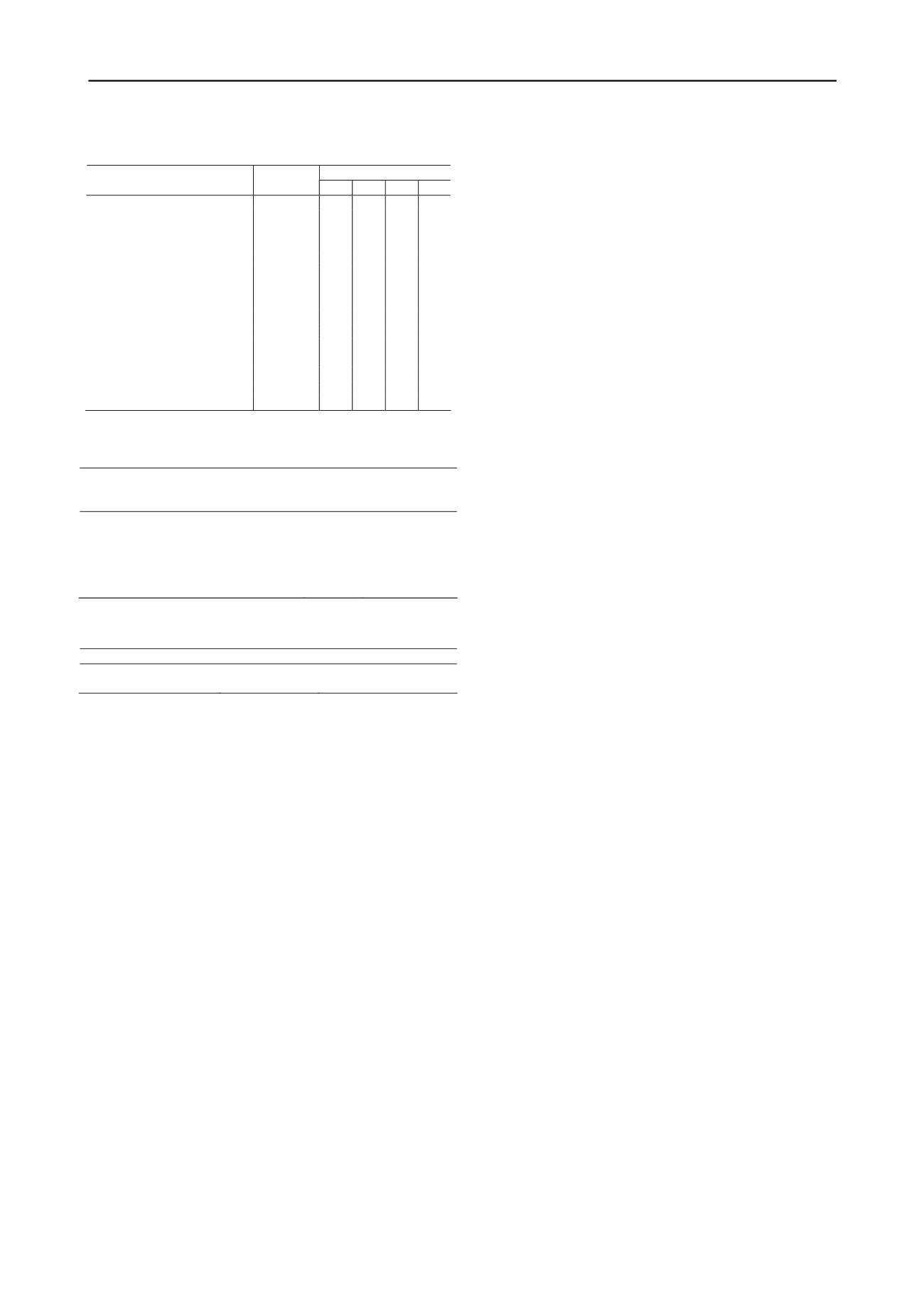

Table 4 – Samples that did not meet the requirements of NBR

15.116:2004.

Samples

Parameters

NBR

15.116

i

i

ii

iii

Uniformity Coefficient (%)

≥ 10

4.88 3.62

39.28 14.88

Material through strainer Nº

40 (%)

Between

10 e

40mm

53.47 45.76

21.47 31.24

CBR (%) - Subgrade

≥ 12

10.20 18.70

190.5 129.7

CBR (%) - Sub-base

≥ 20

10.20 18.70

190.5 129.7

CBR (%) - Base

≥ 60

10.20 18.70

190.5 129.7

Subgrade Expansion

≤ 1

0.20 0.10

0

0

Sub-base Expansion (%)

≤ 1

0.20 0.10

0

0

Expansion (%) – Base

≤ 0,5

0.20 0.10

0

0

Maximum dimension of

grains (mm)

63.5

19.10 19.10 38.10 38.10

Shape Index

< 3.0

*

*

2.20 *

Depreciation

< 50

*

* 26.76 *

Sulphate Content (%)

< 2.0

0

0

0.05 *

i – Soil; ii – RCCR; iii – R60S40

* *Not determined

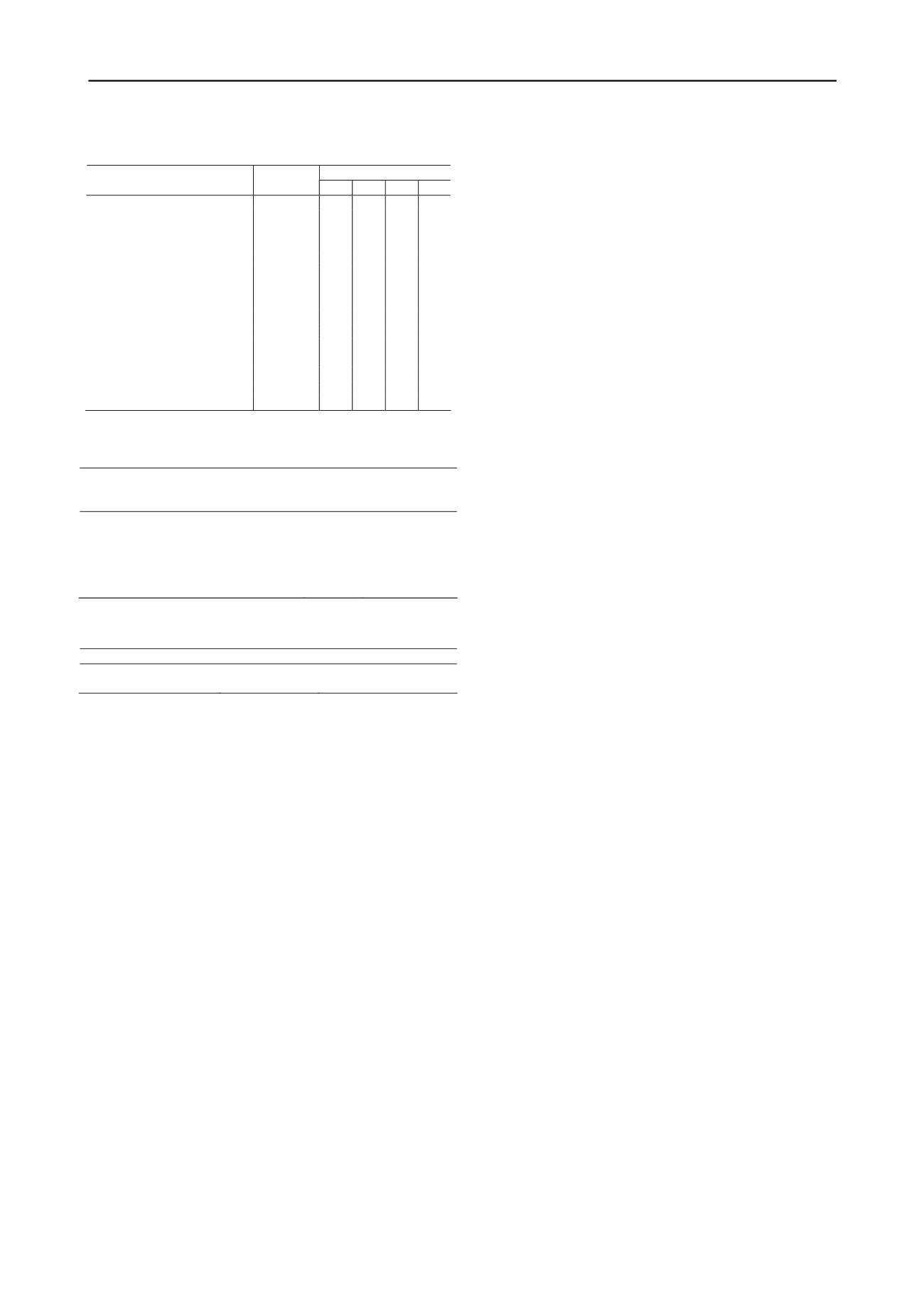

Table 5– Costs of the acquisition of materials for paving project.

Material

Unit

Unitary cost of

the acquisition

(US$)

Sand for landfill

m

3

14,00

RRCC obtained with mobile plant onsite

m

3

14,00

RRCC obtained from processing plant

outside the site

m

3

9,11

Simple graduated gravel (SGG)

m

3

20,41

Soil of the continuous helical pile

m

3

0*

* cost of transportation onsite disconsidered

Table 6 – Costs for the final disposition of wastes in licensed places.

Disposition place

Unit

Unitary cost (US$)

Inert Landfill

m

3

47,30

Processing plant

m

3

18,36

* cost of transportation onsite disconsidered

For the calculation of the financial impact of the use of the

investigated materials in paving project, two scenarios for reuse

of waste were considered:

Scenario 1: all the brute RRCC is taken to the processing

mill for recycling, and the pile soil is deposited in the inert

landfill. The layers of paving are executed with natural

aggregates;

Scenario 2: use of mixture of pile soil with RRCC in the

regularization of the terrain and the sub-base layer. The base

layer is performed with the remaining available RRCC and

another portion of natural aggregate (SGG).

In simulations, the volumes were calculated from the paving

projects (flexible and semi-rigid), land leveling and gabion wall

containment. In all cases, a bulking of 12% was admitted

(project value) and apparent specific weight of RRCC and the

soil is equal to 14 and 17 KN/m

3

, respectively.

The estimation of Scenario 1 presented a cost of US$ 2.2

million, while Scenario 2 showed a total cost of

US$ 320,498.21, in other words, the use of residues represent a

direct saving of about US$ 1.9 million continuing to meet the

technical requirements of the paving project, and allowing a

very significant reduction of environmental impacts that were

not valued.

In the implementation of the paving, the base layer only

contained simple graduated gravel (SGG), as an option of the

designer. Still, the direct saving obtained was almost the same

as in scenario 2.

In summary, demolition residues and the soil from the

excavation of helical piles were transformed into the “worksite

quarry”. The sustainable construction was cheaper than

conventional work, showing the potential of the "green

economy".

6 CONCLUSION

The article presents a case of building a shopping center in

Recife where the excavation residues of the 4,000 helical

foundation piles, in other words, about 25,000 m

3

of soil were

used in the layers of the paving work (regularization of the

terraind and sub-base). Demolition residues were also used from

old existing warehouses on the land, which were transformed

into recycled aggregates with a mobile plant installed at the

worksite.

The demolition residues and soil from the excavation of the

helical piles were transformed into the "worksite quarry". The

sustainable work was cheaper than the conventional

construction, showing the potential of the "green economy".

7 ACKNOWLEDGMENTS

The authors would like to thank the JCPM group for their trust

throughout the development of the study, especially Dr.

Francisco Bacelar. We also thank the Post-Graduation Program

in Civil Engineering of the University of Pernambuco, CAPES

(Brazilian funding agency) and FACEPE (funding agency of the

state Pernambuco).

8 REFERENCES

CÂMARA BRASILEIRA DA INDÚSTRIA DA CONSTRUÇÃO –

CBIC. Construção Civil: Desempenho e Perspectivas. Informativo

Econômico. Brasília, 2011.

Gusmão, A. D. (2008).

Manual de Gestão dos Resíduos da Construção

Civil

. 1a Edição. ISBN: 978-85-60917-04-4. CCS Editora.

Camaragibe.

Gusmão, A. D. (2011). Prática de Fundações no Recife. Fórum da

Construção do Recife.

NBR 7809:1983 NBR 7809:1983 – Agregado graúdo – Determinação

do índice de forma pelo método do paquímetro – Método de ensaio.

ABNT. Rio de Janeiro.