3206

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

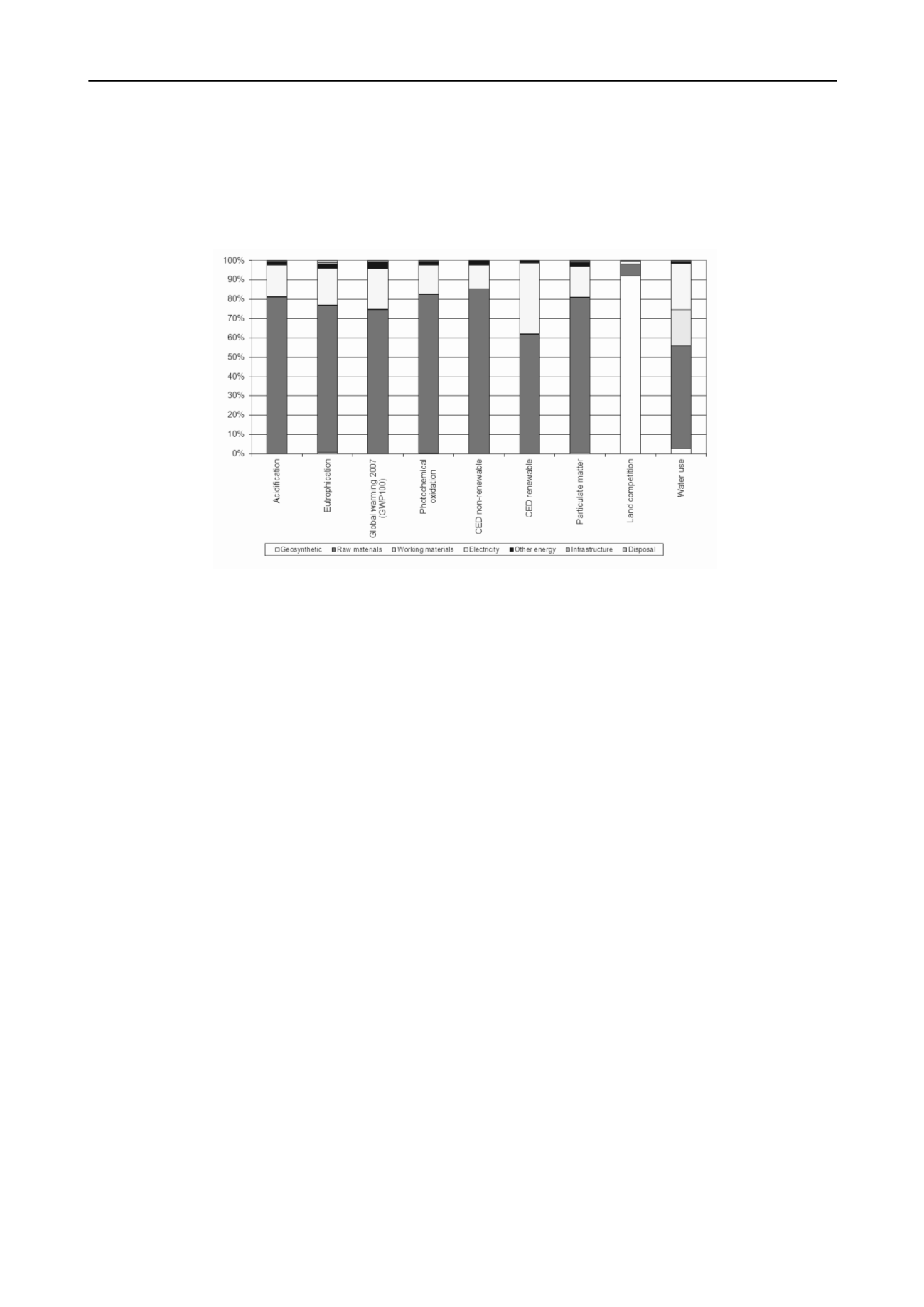

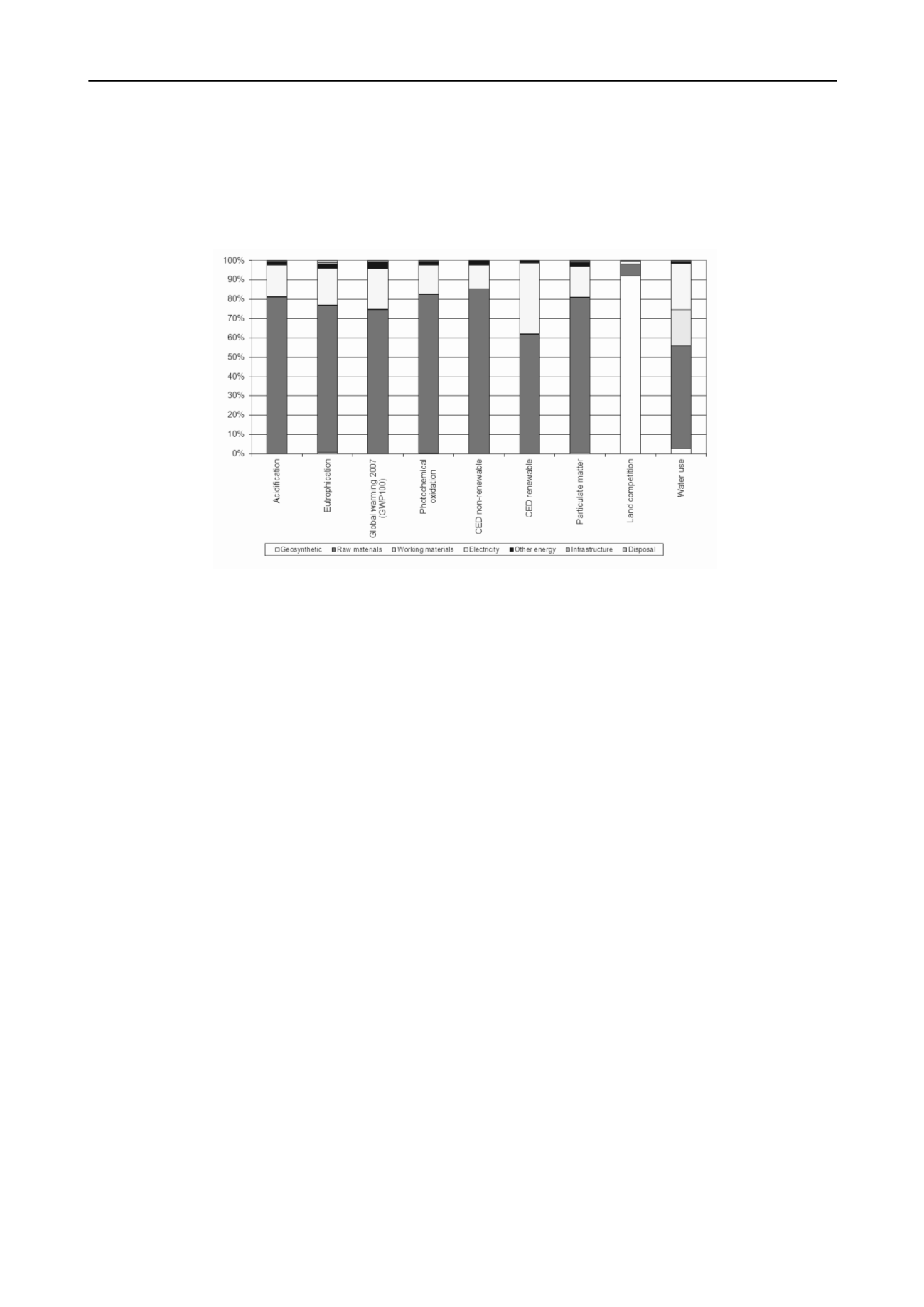

overall impacts). The impacts are dominated by the direct

land use, i.e. land which is occupied by the manufacturer

plant in which the geosynthetic is produced. Indirect land use,

i.e. land occupation stemming from upstream processes, is

significantly lower because no land occupation is reported in

the inventories of plastic feedstock and no land intensive

products such as wood are used in considerable amounts.

Water consumption (tap water, deionised water, decarbonised

water) is included in the working materials. As a

consequence, this category bears about 15°% of the total

amount of water used.

Figure 3. Environmental impacts of the life cycle of 1 kg geosynthetic layer. Geosynthetic includes direct burdens of the geosynthetic production. Raw

materials include plastic, extrusion if necessary, and additives, working materials include water (tap and deionised) and lubricating oil, other energy

includes thermal energy and fuels, infrastructure covers the construction of the production plant and disposal comprises wastewater treatment and

disposal of different types of waste.

5 DISCUSSION AND CONCLUSION

A filter using a geosynthetic layer causes lower environmental

impacts compared to a conventional gravel based filter layer

with regard to all impact category indicators investigated. If

30 cm of gravel are saved, the specific climate change impact of

the construction of 1 square meter filter using geosynthetics is

about 7 kg CO

2

-eq lower compared to the impacts from the

construction of an equivalent gravel based filter.

The difference is considerable for all indicators (more than

85 %) and reliable. The difference in the environ¬men¬tal

impacts arises mainly because the applied geosynthetic

substitutes gravel, which causes considerably higher impacts

when extracted and transported to the place of use. At least a

layer of 8 cm of gravel must be replaced by geosynthetics used

as a filter in order to cause the same or lower environmental

impacts regarding all indicators.

The environmental impacts of the gravel based filter are

significantly reduced, when constructing smaller filters (20 cm

instead of 30 cm). Nevertheless, the sequence of the two cases

does not change and the difference is still significant between

the sensitivity cases of the mineral filter and the geosynthetic

filter.

6 REFERENCES

ecoinvent Centre (2010) ecoinvent data v2.2, ecoinvent reports No. 1-

25. Swiss Centre for Life Cycle Inventories, Duebendorf,

Switzerland, retrieved from:

.

Frischknecht R., Jungbluth N., Althaus H.-J., Bauer C., Doka G., Dones

R., Hellweg S., Hischier R., Humbert S., Margni M. and Nemecek

T. (2007) Implementation of Life Cycle Impact Assessment

Methods. ecoinvent report No. 3, v2.0. Swiss Centre for Life Cycle

Inventories, Dübendorf, CH, retrieved from:

.

Goedkoop M., Heijungs R., Huijbregts M. A. J., De Schryver A., Struijs

J. and van Zelm R. (2009) ReCiPe 2008 - A life cycle impact

assessment method which comprises harmonised category

indicators at the midpoint and the endpoint level. First edition.

Report I: Characterisation, NL, retrieved from: lcia-recipe.net/.

Guinée J. B., (final editor), Gorrée M., Heijungs R., Huppes G., Kleijn

R., de Koning A., van Oers L., Wegener Sleeswijk A., Suh S., Udo

de Haes H. A., de Bruijn H., van Duin R., Huijbregts M. A. J.,

Lindeijer E., Roorda A. A. H. and Weidema B. P. (2001a) Life

cycle assessment; An operational guide to the ISO standards; Part

3: Scientific Background. Ministry of Housing, Spatial Planning

and Environment (VROM) and Centre of Environmental Science

(CML), Den Haag and Leiden, The Netherlands, retrieved from:

Guinée J. B., (final editor), Gorrée M., Heijungs R., Huppes G., Kleijn

R., de Koning A., van Oers L., Wegener Sleeswijk A., Suh S., Udo

de Haes H. A., de Bruijn H., van Duin R., Huijbregts M. A. J.,

Lindeijer E., Roorda A. A. H. and Weidema B. P. (2001b) Life

cycle assessment; An operational guide to the ISO standards; Parts

1 and 2. Ministry of Housing, Spatial Planning and Environment

(VROM) and Centre of Environmental Science (CML), Den Haag

and

Leiden,

The

Netherlands,

retrieved

from:

PRé Consultants (2012) SimaPro 7.3.3, Amersfoort, NL, retrieved from:

.

Solomon S., Qin D., Manning M., Alley R. B., Berntsen T., Bindoff N.

L., Chen Z., Chidthaisong A., Gregory J. M., Hegerl G. C.,

Heimann M., Hewitson B., Hoskins B. J., Joos F., Jouzel J., Kattsov

V., Lohmann U., Matsuno T., Molina M., Nicholls N., Overpeck J.,

Raga G., Ramaswamy V., Ren J., Rusticucci M., Somerville R.,

Stocker T. F., Whetton P., Wood R. A. and Wratt D. (2007)

Technical Summary. In: Climate Change 2007: The Physical

Science Basis. Contribution of Working Group I to the Fourth

Assessment Report of the Intergovernmental Panel on Climate

Change (IPCC), Cambridge University Press, Cambridge, United

Kingdom and New York, NY, USA.

Stucki M., Büsser S., Itten R., Frischknecht R. and Wallbaum H. (2011)

Comparative Life Cycle Assessment of Geosynthetics versus

Conventional Construction Material. ESU-services Ltd.

commissioned by European Association for Geosynthetic

Manufacturers (EAGM), Uster and Zürich, CH.