3201

Technical Committee 307 /

Comité technique 307

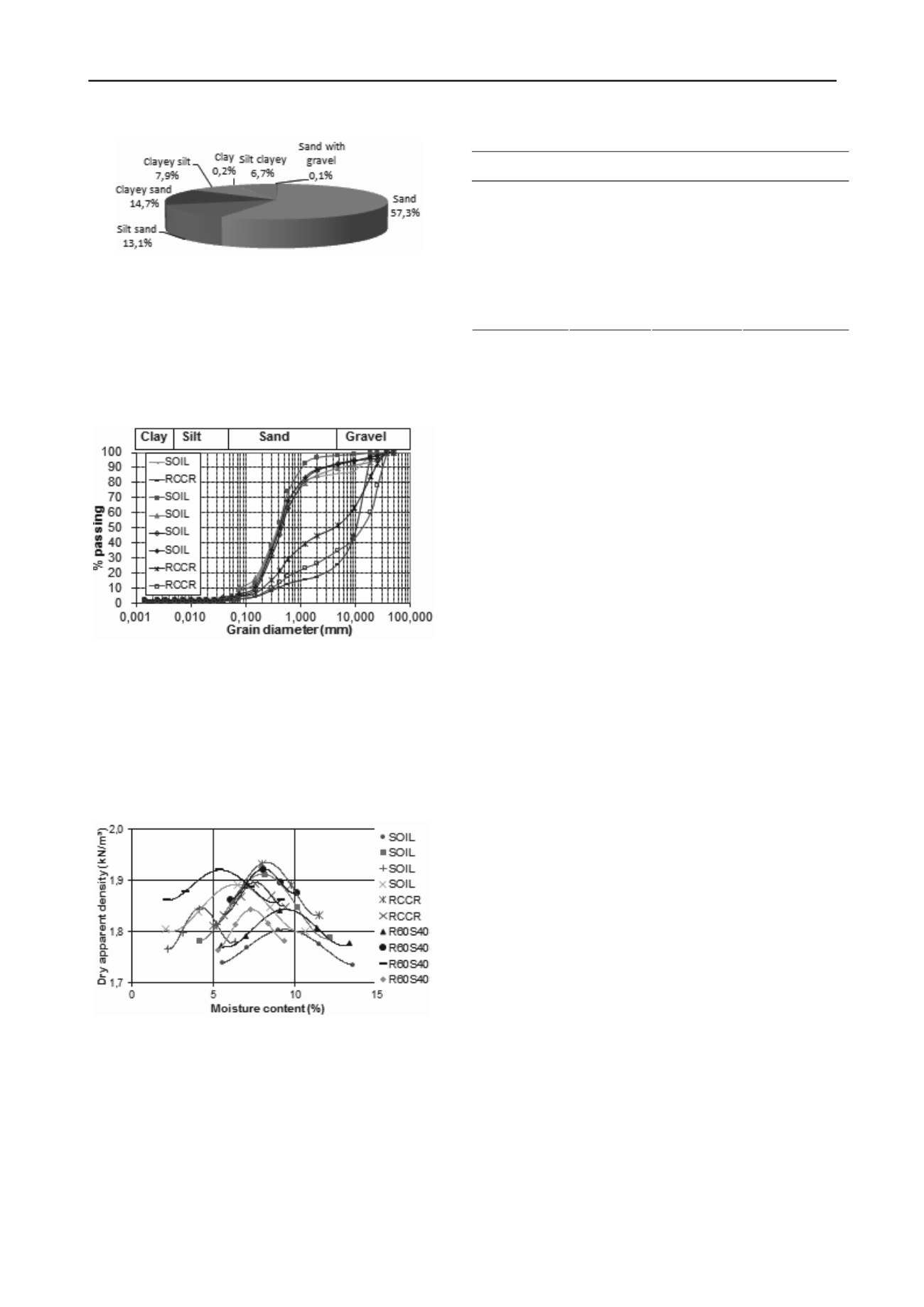

Figure 2 – Prediction of the excavated soil by piles through assays

.

5.3 Granulometry

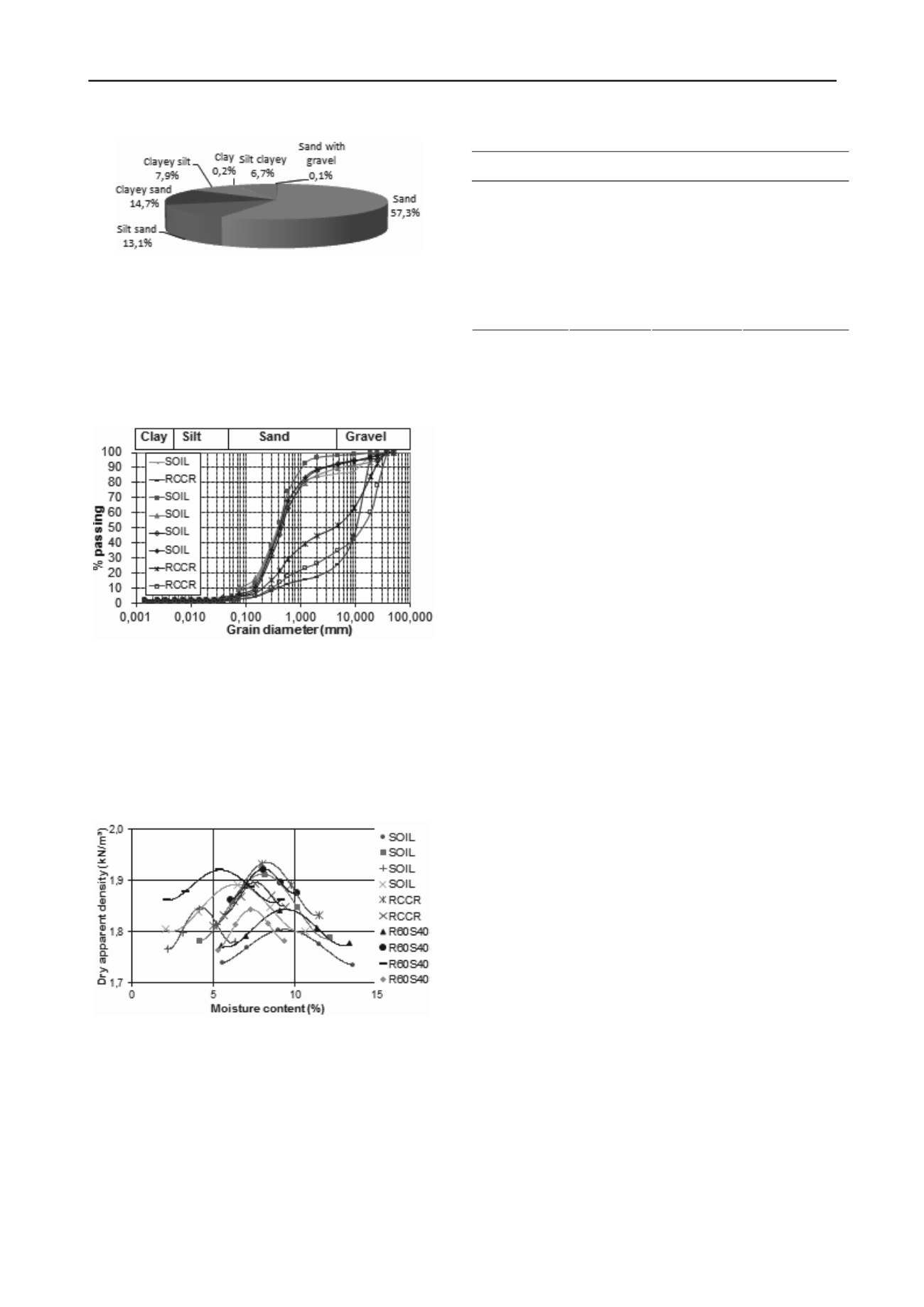

Figure 3 shows the granulometric curve of soil samples and of

RRCC. It is observed that the RCCR is classified as gravel with

thick and medium-sized sand. On the other hand, the soil is

medium-sized and thin sand, which coincides with the prior

prediction made by the assays.

Figure 3 – Grain size curve of soil and of RRCC.

5.4 Compaction curves

Figure 4 shows some compaction tests with intermediate

energy. It is observed that the optimum moisture varies between

4.1 and 9.1%, which are typical values for granular soils. It is

also observed that the mixture soil + RRCC presented higher

densities than the materials isolated, probably due to the fact

that a higher degree of the group was reached.

Figure 4 – Compaction Curves for soil, RRCC and mixture.

5.5 California Bearing Ratio (CBR)

Table 3 shows the CBR values obtained for the soil, RRCC and

mixture of 60% RRCC and 40% soil (R60S40). The average

values were equal to 39, 189 and 115%, respectively. The

expansion values ranged from 0 to 0.2%.

Table 3 – Summary of the CBR values.

Material

CBR (%)

Avarage

Value (%)

Variance

Coefficient (%)

10

76

19

Soil

51

39

78

191

RCCR

188

189

1

84

108

130

R60S40

138

115

21

Regarding the NBR 15.116/04, for the possibility to use

recycled material in the sub-base layers and pavement bases,

CBR minimum is of 20% and 60%, respectively, implying that

all mixtures have adapted to the requirements of the standard.

5.6 Shape Index

As the shape index approaches only the coarse aggregate with

maximum characteristic dimension superior to 9.5 mm, only the

RRCC samples were assayed. According to NBR 7809:1983,

the maximum limit in the relation length/thickness is 3.0. This

condition was met in both samples.

5.7 “Los Angeles” Abrasion

Just as in shape index, the "Los Angeles" abrasion test refers

only to the coarse aggregate. For the two RRCC samples, the

values were equal to 26.8 and 26.3% of depreciation, which are

below the maximum limit of 50% set in the standard.

5.8 Sulphate levels

The maximum level of sulphate in relation to the mass of the

recycled aggregate is 2%, according to NBR 15.116:2004. The

values obtained in the assays of the soil and RRCC ranged

between 0.04 and 0.09%, in other words, they were below the

maximum limit set in the standard.

5.9 Technical Feasibility for using CDW in Paving Projects

Table 4 summarizes the results of some samples of soil, RRCC

and the mixture soil-RRCC, comparing the values with the

recommendation of NBR 15.116:2004. It was observed that

only the soil did not meet the requirements for the use in paving

layers. However, both the isolated RRCC as well as mixed with

soil from the excavation of piles, meet all the criteria of the

standard.

5.10 Economic feasibility of the use of CDW in paving projects

For the study of the economic feasibility of using CDW in

paving layers in the project, an inquiry of the unitary cost of the

acquisition of the aggregates specified in the paving project was

initially performed, whose values are shown in Table 5. The

costs of implementing the layers were not considered in the

comparison, as it would be the same with the use of natural

aggregates or CDW.

Table 6 shows the costs for the disposal at two sites licensed

by the environmental agencies, which is an inert landfill or a

processing plant for CDW. Both are located in the Metropolitan

area of Recife.