3193

Technical Committee 307 /

Comité technique 307

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3

Table 3. Chemical properties of the MgCl

2

solutions used for the Batch

Sorption test

MgCl

2

(mg/L)

EC (mS/cm)

Salinity (-)

pH

100

0.301

0.0

6.87

200

1.382

0.5

7.04

2000

4.16

2.1

7.3

6000

12.13

6.46

7.7

3.2

Hydraulic conductivity test

Flexible wall hydraulic conductivity tests were conducted in

order to investigate the impact of 8% of polymer addition on the

hydraulic performance of the soils to a high concentrated

electrolyte solution (natural seawater). The hydraulic

conductivity tests were performed with an average effective

stress of 30 kPa on 10 cm diameter samples with an initial

porosity of about n = 0.718 (kaolin) and n = 0.542 (dredged

sediment). To prepare the kaolin samples, the untreated and

treated soil were poured dry in a stainless steel ring (0,45g/cm²,

as a standard GCL, 10 cm diameter) with a fixed height between

two porous stones and submerged with seawater, with a sitting

weight on top, for about one week. The dredged sediment

sample was prepared by standard proctor compaction (ASTM

D0698) with a water content two points higher than the

optimum, to simulate a Compacted Clay Liner.

4

RESULTS AND DISCUSSION

4.1

Batch sorption test results

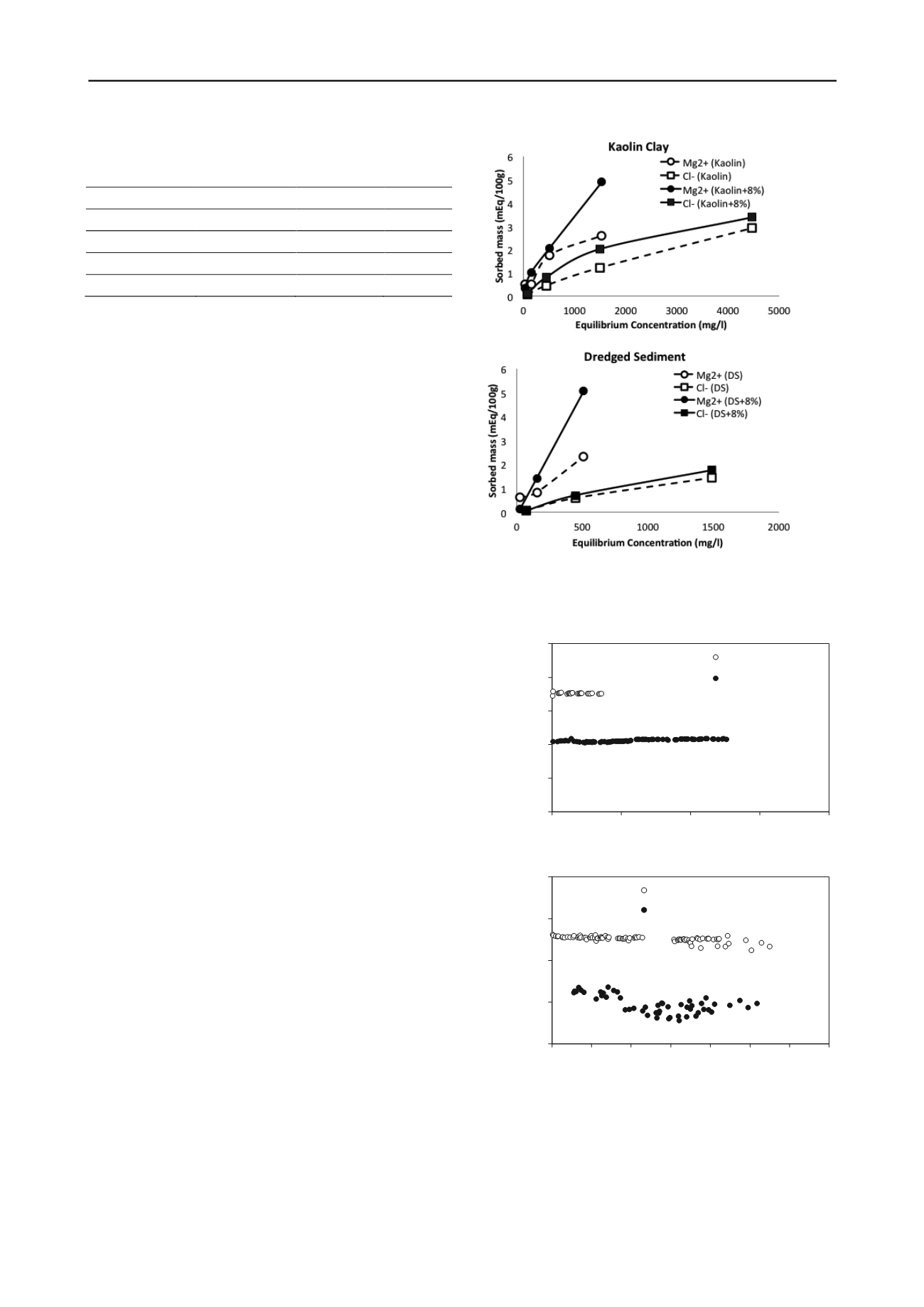

Figure 1 shows the sorption isotherms of the treated and

untreated kaolin (a) and of the treated and untreated dredged

sediment (b). The adsorbed mass of ions is plotted here vs. the

equilibrium concentration of the MgCl

2

solutions. As shown in

the graphs, batch sorption test results demonstrate that the

sorbed mass of magnesium cations is higher onto the polymer

treated soil compared to the untreated soil.

4.2

Hydraulic conductivity test results

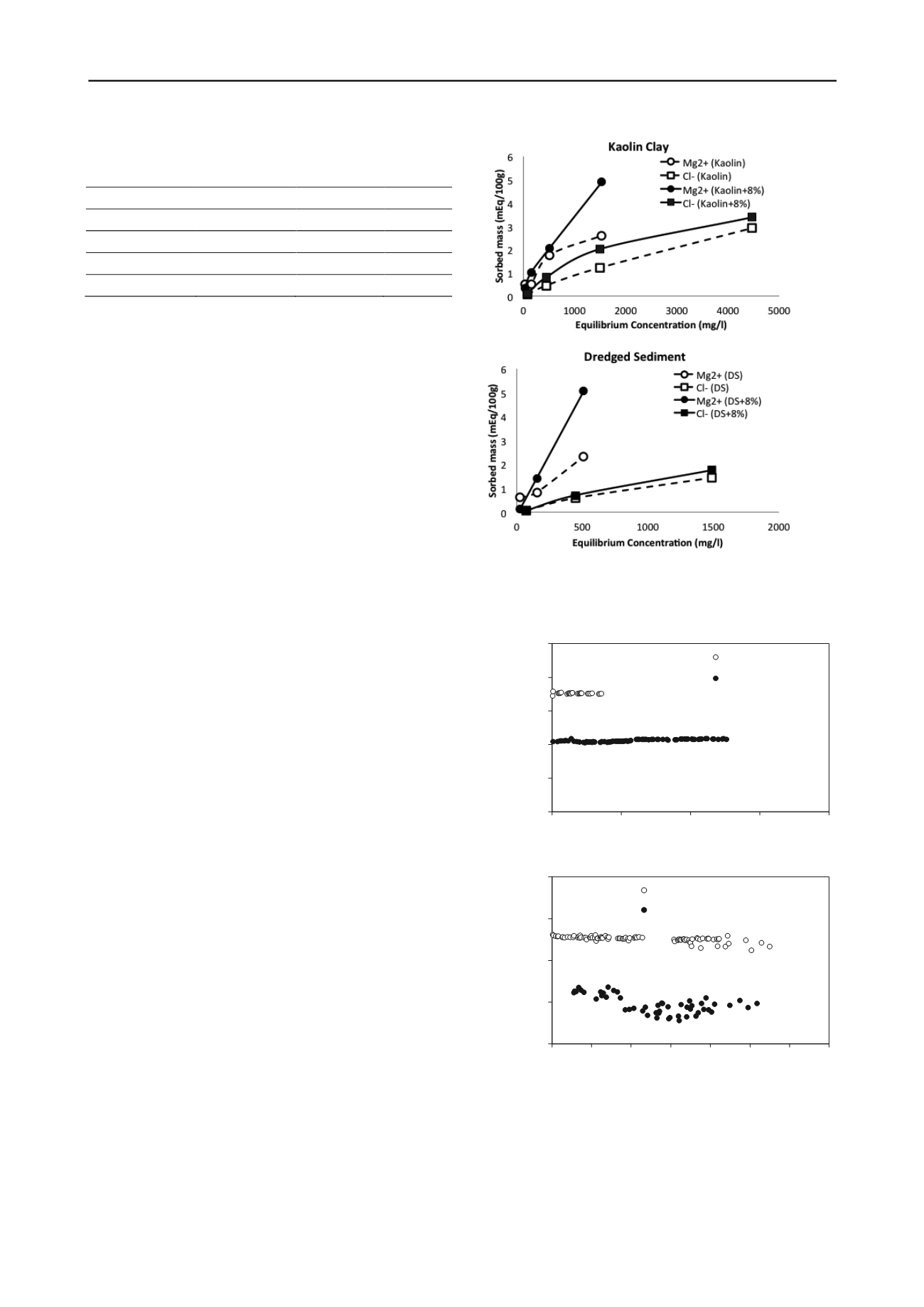

Figure 2 shows the hydraulic conductivity test results of the

treated and untreated soils. As shown in Figure 2.a, the

hydraulic conductivity to seawater of the kaolin treated with 8%

of the polymer was lower compared to that of the kaolin treated

with 2% of the polymer. This result demonstrates that the

hydraulic performance of a kaolin clay as barrier increases with

increasing polymer dosage.

Figure 2.b shows that the hydraulic conductivity to seawater

of the dredged sediment treated with 8% of the polymer is

nearly two orders of magnitude lower compared to that of the

untreated dredged sediment.

(a)

(b)

Figure 1. Sorption isotherms of kaolin (a) and dredged sediment, DS (b)

1.E-12

1.E-11

1.E-10

1.E-09

1.E-08

1.E-07

0

50

100

150

200

Hydraulic conductivity [m/s]

Time [days]

kaolin + 2% CMC

kaolin + 8%CMC

(a)

1.E-12

1.E-11

1.E-10

1.E-09

1.E-08

0

50 100 150 200 250 300 350

Hydraulic conductivity [m/s]

Time [days]

Dredged Sediment

Dredged Sediment + 8%CMC

(b)

Figure 2. Hydraulic conductivity test results of (a) kaolin clay 2% CMC

and 8% CMC, and (b) dredged sediment and dredged sediment treated

with 8% CMC, permeated with natural seawater