3189

Technical Committee 307 /

Comité technique 307

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

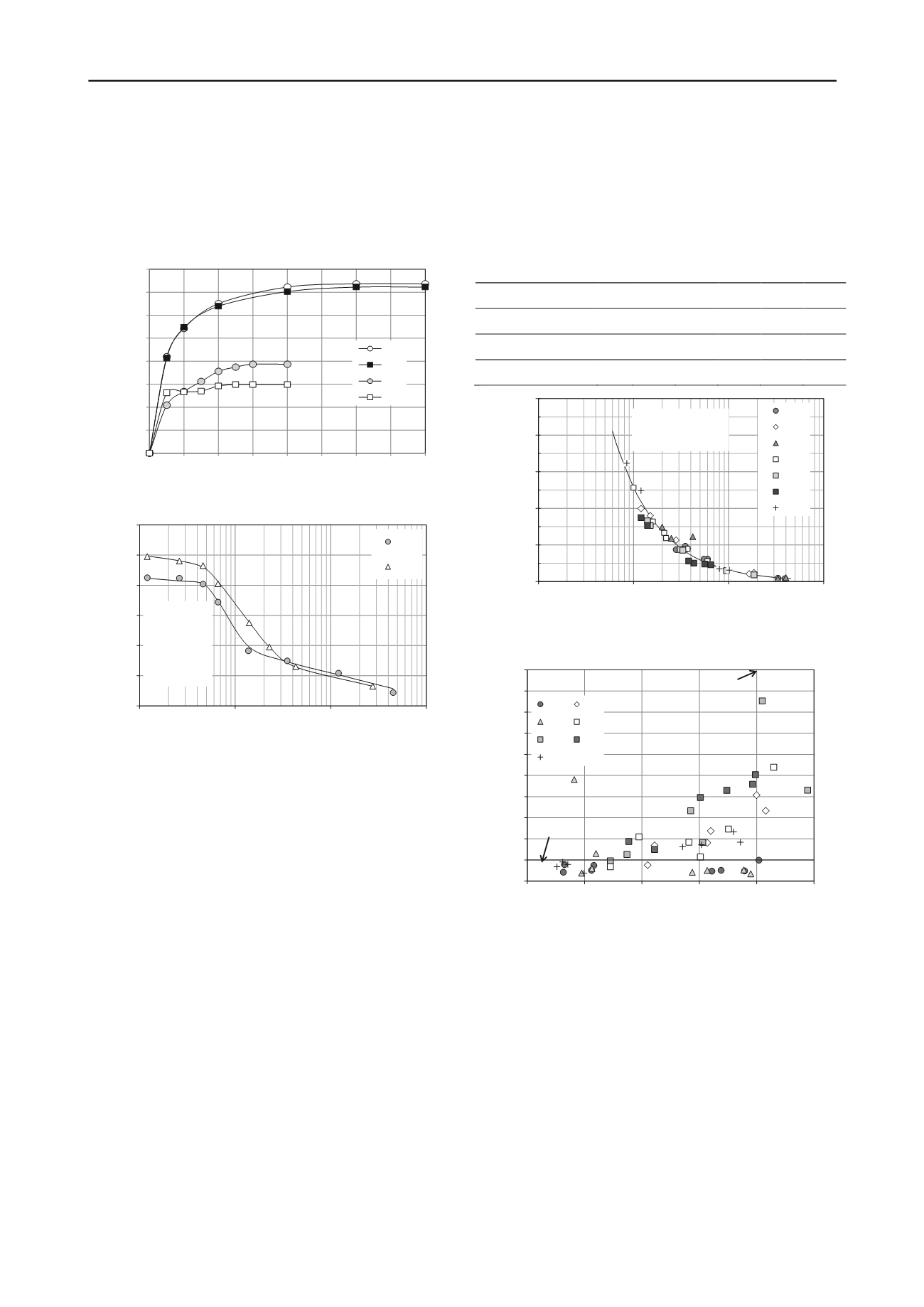

2012 for details of the filter paper method) for suctions greater

than 20 kPa. The SWCC plots of gravimetric moisture content

against matric suction are provided in Figure 2 for the 2 blends

with 20% RCM. Air entry values (u

ae

) were the same for these

two samples but the residual suction (u

r

) differed (15 and 30

kPa). The air entry values were within the range reported for

RCA by Rahardjo et al. 2010.

Figure 1. Shrinkage curves for the recycled materials

Figure 2. SWCC for materials A20 and B20

6 STATIC AND REPEATED LOADING RESULTS

Undrained shear strength data are indicated in Table 2 for

material prepared at a target of relative moisture content of 80%

OMC. The last row contains nominal shear strength values

based on the shear strength parameters and a normal stress of

100 kPa. The nominal shear strength decreased generally with

masonry content for the B samples, but the A samples seemed

unaffected.

Shear strength increased with matric suction or decrease of

relative moisture content. Between target moisture contents of

90 and 60% OMC, on average the nominal shear strength of the

recycled materials increased by 13%, while the quartzite

strength was improved by 9%.

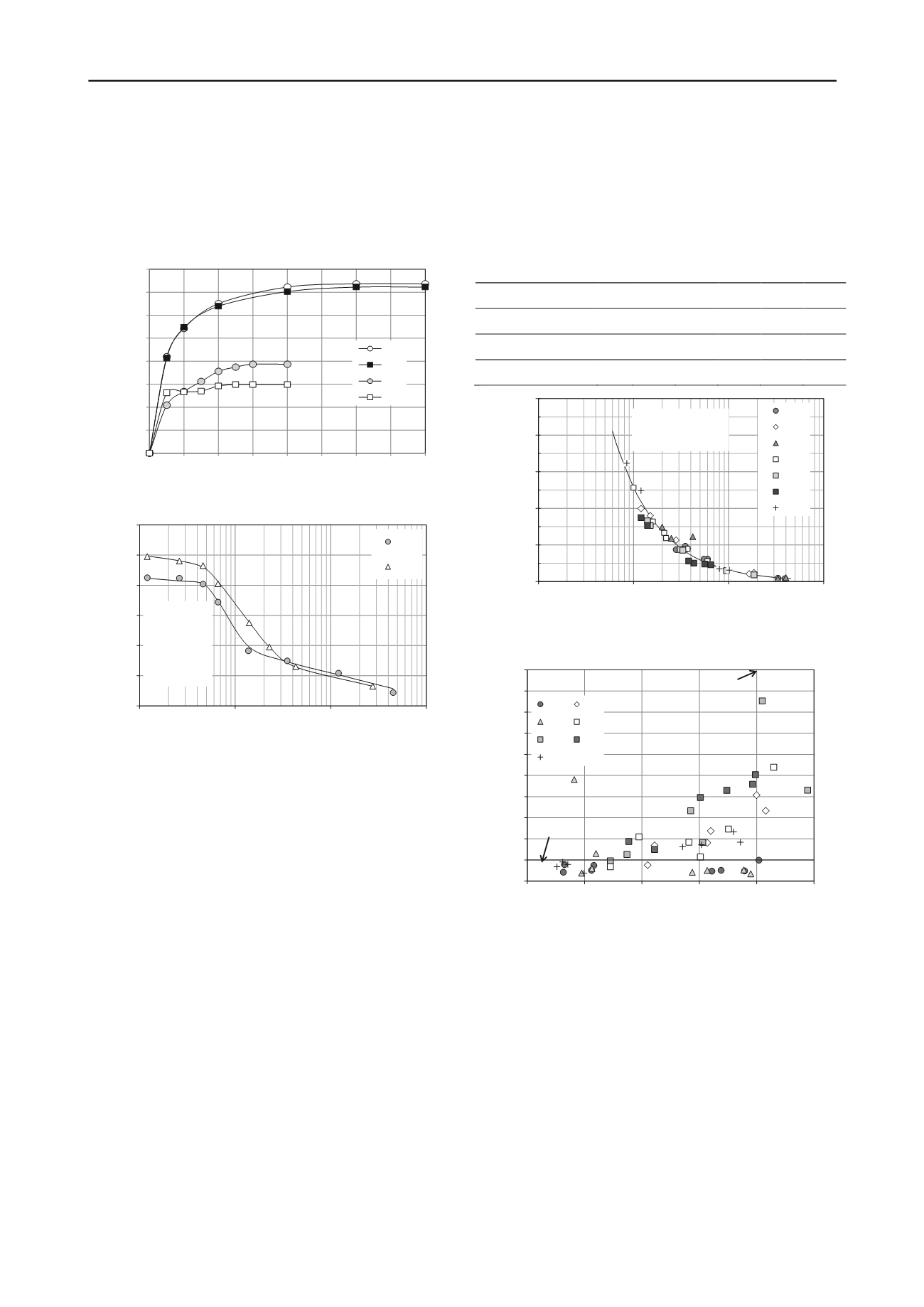

The resilient modulus of the RCA products (materials A and

B) varied between 500 and 950 MPa, clearly surpassing the

DPTI 2011 requirement of 300 MPa. Generally resilient

modulus decreased with moisture content although product A

had a fairly constant modulus of approximately 600 MPa. The

materials blended with crushed masonry performed well also.

Even material B30 had a minimum modulus greater than 400

MPa. A relationship between initial matric suction and resilient

modulus from the single stress stage of the DTEI test protocol,

was developed and is illustrated in Figure 3. A simple power

model fit the data for all materials adequately. The power

function is consistent with the findings of Gupta et al. 2007.

Further work is underway on predicting the resilient modulius

from multi-stage triaxial stress testing (stress dependent model).

The DPTI specification for Class 1 material requires a

minimum rate of permanent strain over the last 30,000 load

cycles of -1x10

-8

% per cycle. RCA performance was generally

acceptable for Class 1 (refer Figure 4) although the blends with

RCM were more appropriate for Class 2 applications. The

quartzite material, Q, failed to make the DPTI Class 1 limit

when prepared at 80% OMC or wetter.

Table 2. Undrained shear strength (80% OMC)

Material

A A20 B B10 B20 B30

Cohesion (kPa)

163 134 41

9

46

0

Friction angle (

)

48 55 60 53 44 53

Nom. strength (kPa) 277 274 214 142 143 133

Figure 3. Resilient modulus as a function of initial matric suction

Figure 4. Permanent strain rate as a function of initial moisture content

7 PERMANENT STRAIN MODELLING

Gabr and Cameron 2012b proposed a predictive model for

permanent strain from multi stage RLLT data on RCA materials

A and B, and virgin aggregate, Q. Permanent strain increased

with increase in either mean stress ratio (current stress to failure

stress) or moisture content. The proposed model required mean

normal stress, shear stress ratio, number of cycles, moulding

moisture content, dry density and weighted plasticity index.

The model was found to fit very well the permanent strain

for each material. An example is given in Figure 5. It was

acknowledged by Gabr 2012 that the model attempeted to

predict permanent strain over all material shakedown ranges,

and so required further validation before confident application

to prediction of rutting in pavements.Nonethless Gabr used

finite element analysis of the impact of a single wheel load on a

thin unsealed pavement, 320 mm thick, over a sand subgrade, to

0

200

400

600

800

1000

1200

1400

1600

0 14 28 42 56 70 84 98 112

A

B

A20

B20

Shrinkage (

μ

strain)

Drying Days

6

8

10

12

14

16

18

1

10

100

1000

Water Content (%)

Matric Suction (kPa)

A20

B20

A20:

u

ae

= 5 kPa

u

r

= 15 kPa

B20:

u

ae

= 5 kPa

u

r

= 30 kPa

0

20

40

60

80

100

1

10

100

1000

A

A20

B

B10

B20

B30

Q

Initial Matric Suction (kPa)

Resilent Modulus (MPa)/ Matric Suction

M

r

/u

m

= 422.5 u

m

-0.914

R² = 0.975

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

50

60

70

80

90

100

Permanent Strain Rate (%/cycle x 10

-8

)

Relative Moisture Content (%)

A A20

B B10

B20 B30

Q

Maximum allowable for Class 2

Maximum allowable

for Class 1