3200

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 CHARACTERIZATION OF THE ENTERPRISE

It consists in the construction of a horizontal shopping center in

Recife, Pernambuco, Brazil. The edification is formed by an

pre-molded arched concrete structure with a total construction

area (shopping areas and garages) of 255,500 m².

From the topographic point of view, the natural terrain did

not possess pronounced leveling differences. As for the

geological point of view, the land is located in the fluvial-

marine plain, within the undifferentiated marine terrace.

On the terrain of the enterprise, there were 07 major

warehouses and 10 smaller deposits, totaling an area of

20,949 m² of demolition, responsible for generating

approximately 18,900 tons or 13,500 m³ of CDW. Considering

also the temporary installations and concrete slabs of the service

paths, it is estimated that globally 23,560 tons or 16,830 m³ of

CDW were generated.

Given the geotechnical characteristics of the land and

construction schedule, continuous helical piles were designed

and implemented for the foundation of all edifications. Table 1

shows the total quantitative at the end of the work, as well as the

production of excavated soil. A total of 25,013m ³ or 42,522

tons of soil (admitting an apparent specific weight of 17 kN/m³).

There is, therefore, a total waste (demolition + soil deriving

from piling) of 66.082 tons. If all this material was taken to a

licensed landfill, the cost of provision would be of US$

28,00/ton, or a total of US$1.9 million, besides environmental

costs.

Having this in mind and the large area of paving of the site, a

technical and economic study for the reuse of waste from the

excavation residues in the pavement layers of the work was

proposed. The excavated material was then separated and stored

in an area of the own work site.

Table 1 – Quantitative of piles.

Diameter of

Pile

Quantity

Length

Medium (m)

Excavated Soil

(m

3

)

400

504

21.68

1,713

500

2,965

23.30

17,506

600

692

22.67

5,794

3 PAVING OF THE ENTERPRISE

The total paved area of the work was of 96,463 m² and is in

accordance with the specifications of the paving project, the

sub-base layer in the circulation of the exterior parking lot

(flexible pavement) should be stabilized granulometrically with

sandy material, and have a thickness of 0.20 m and minimum

California Bearing Ration (CBR) of 20%.

In the parking spaces outside (semi-rigid pavement), the sub-

base layer should consist of improved soil with 4% cement,

0.10 m thick and minimum CBR of 20%.

Data showed that the paving and land leveling work would

require 22,631 m³ of natural noble aggregates, in other words,

there was a potential for the use of much of the residues in the

work site.

4 METHODOLOGY

In order to enable the use of its own wastes in the paving

projects of the work, the following actions were established:

i) Processing of waste from demolition of the warehouses

through a mobile unit installed at the construction site.

These wastes are in this paper called recycled residues

of civil construction - RRCC;

ii) Separation and storage of excavated soil in the

implementation of continuous helical piles;

iii) Conduction of laboratory tests to characterize the RRCC

and the excavated soil.

For the study of the technical viability of the use of

excavated soil in the paving process, several laboratory tests in

four distinct phases were conducted, whose tests are

summarized in Table 2.

Table 2 – Summary of the characterization tests and assayed samples.

Phase

RRCC or Mixture

Tests

1

Soil, RRCC, R30S70

and R60S40

Granulometry, CBR and Limits

of Consistency

2

Soil, RRCC and

R60S40

Granulometry, Limits of

Consistency, Real Density of

grains, Compactation, CBR,

shape Index, Abrasion “Los

Angeles” e Level of sulphates

3

R40S60 (samples

collected in

experimental field)

Granulometry, Compactation

and CBR

4

RRCC, R60S40,

R40S60 e R30S70

(samples collected in

experimental field)

Compactation, Humidity

in

situ,

Density in

situ

(Sand

Flask)

RRCCR – recycled residues of civil construction; R30S70 – 30% RCCR

+ 70% pile soil; R40S60 – 40% RCCR + 60% pile soil; R60S40 – 60%

RCCR + 40% pile soil

5 TECHNOLOGICAL CHARACTERIZATION OF THE

MATERIAL

5.1 Composition of RRCC

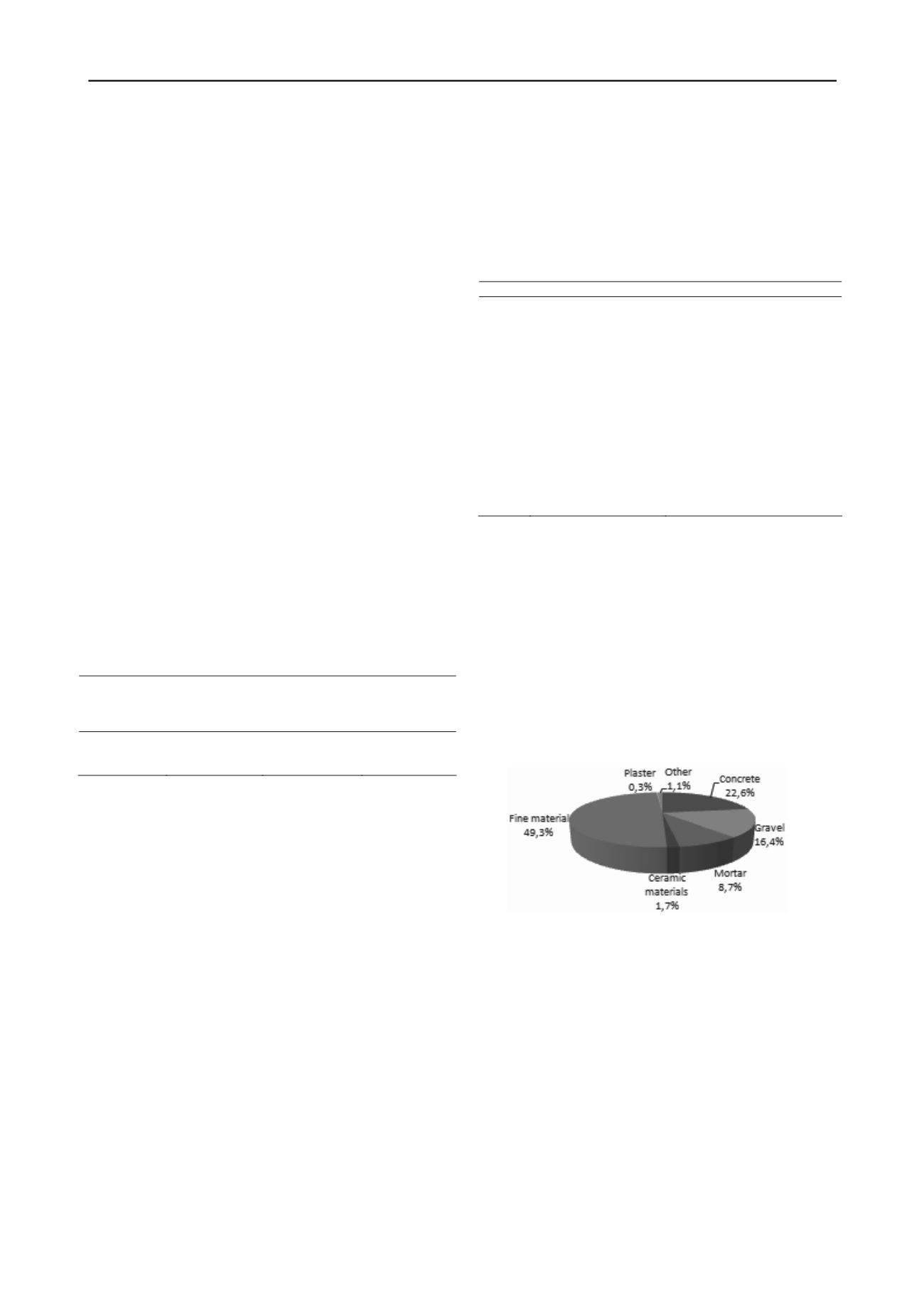

Figure 1 shows the gravimetric composition of RRCC. It is

observed that is predominant the concrete, since warehouses

had large areas of concrete floor. In the small material, with

diameter less than 4,8 mm, it was not possible to differentiate

the waste just by sight.

Figure 1 – Gravimetric composition of RRCC.

5.2 Composition of the excavation soil

For the development of the design of the foundations of the

project, a total of 65 reconnaissance assays for percussion were

performed. Initially, it was thought that the land would present

deposits of soft soils, which are typical for this region of the

city, but tests showed a basement formed by predominantly

sandy soils.

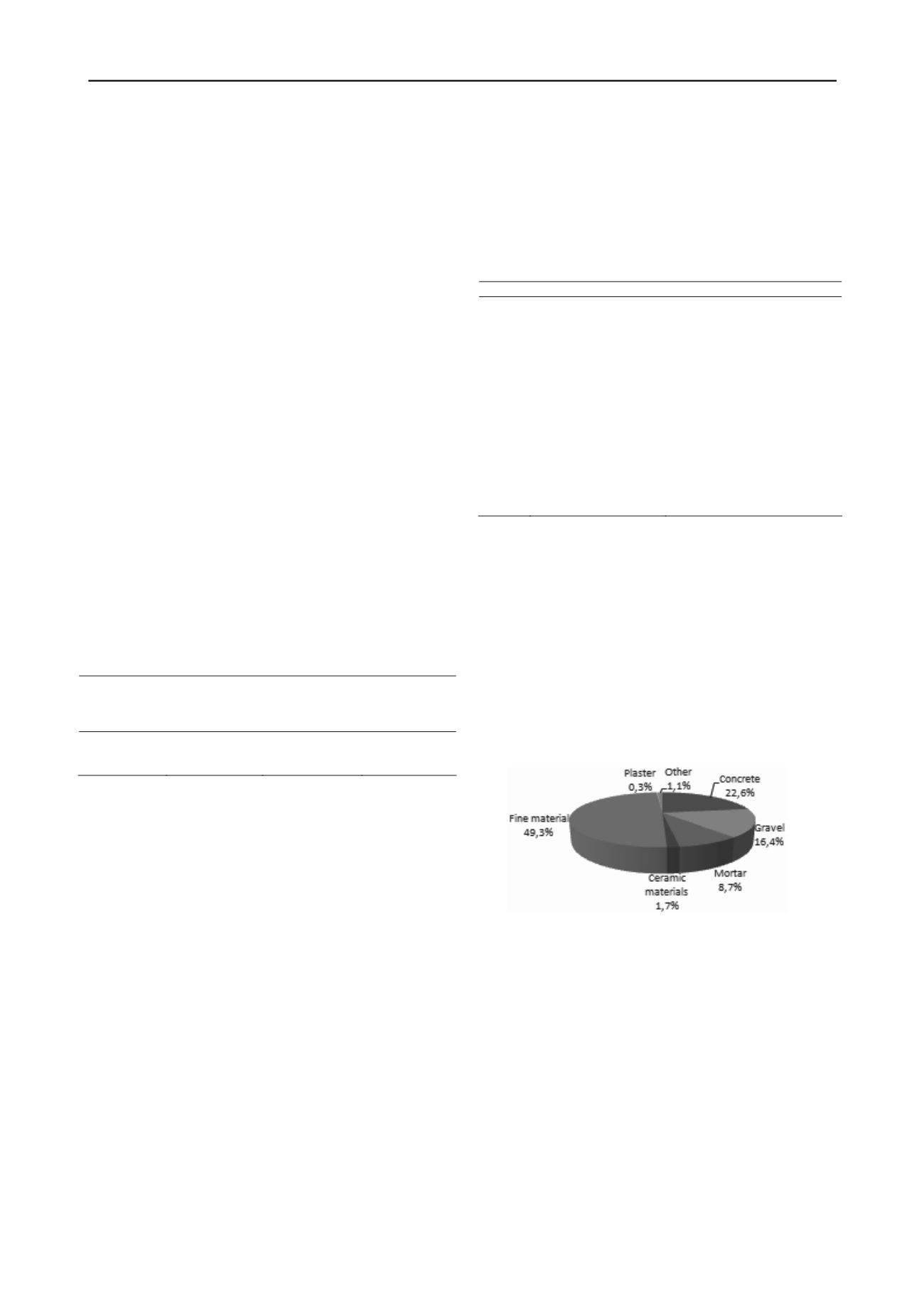

Figure 2 shows the prediction of the type of excavated soil

obtained from surveys conducted initially in the terrain. It is

observed that sandy soils represent 85% of total soils present in

the subsoil up to an average depth of 23m. The major difficulty

in reusing soil from the excavation of a pile is that the excavated

material is the result of full depth of the pile, and there are no

means to segregate it. For a stratified profile, a completely

heterogeneous material will be found.