3030

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

respectively. Based on these two parameters, the clay samples

were classified as saline-alkali soils (Richards 1954).

Sample preparation for the hydraulic conductivity testing

involved moisture conditioning with saline CSG water (CW)

and deionised water (DW), and compaction to 90%, 95%, 98%

and 100% of the maximum dry densities (MDD) at the optimum

moisture contents (OMC) and at a nominal 3% wet of the

optimum moisture contents (wet of OMC), based on the

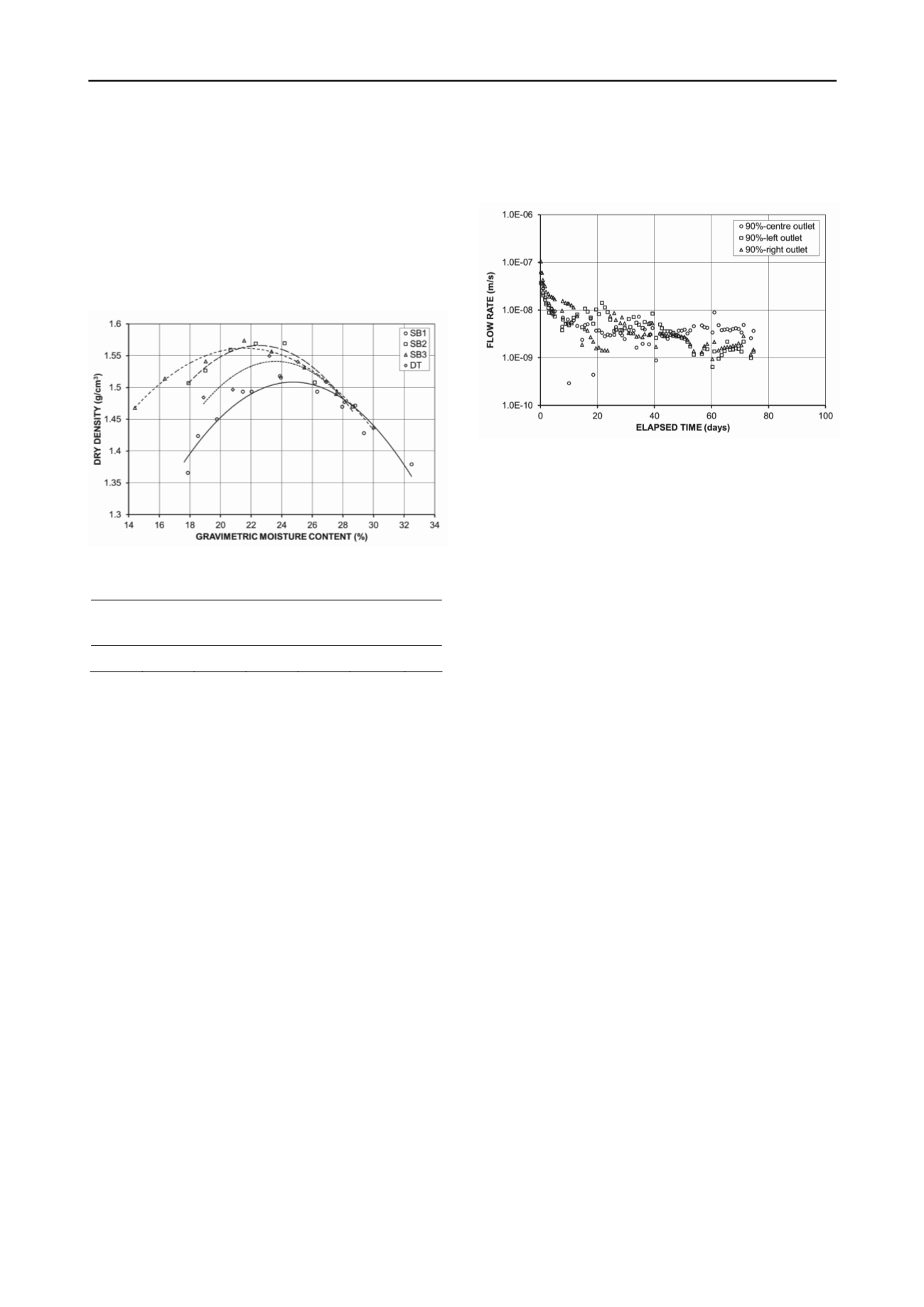

compaction curves shown in Figure 1. The concentrations of the

major ions, EC, and pH of the CW are presented in Table 2.

Figure 1. Compaction curves for clay samples.

Table 2. Chemistry of saline CSG water.

Cl

-

(mg/l)

Na

+

(mg/l)

Mg

2+

(mg/l)

Ca

2+

(mg/l)

K

+

(mg/l)

EC

(dS/m)

pH

789 1484

11

8

8

5.8

9.6

3 HYDRAULIC CONDUCTIVITY TESTING

3.1

Compaction mould testing

Specimens were compacted to the specified dry density at the

specified moisture content in a 144 mm diameter by 130 mm

high modified compaction mould permeameter. The initial

height of each compacted specimen was limited to 50 mm, to

allow space for the specimen to swell to its maximum capacity,

as would occur in the field. Prior to a test, no attempt was made

to saturate the specimen, simulating the field condition in which

a clay liner will not be fully saturated prior to the ponding of

CSG water. A 100 kPa constant water pressure was gradually

applied to top of the specimen to simulate a 10 m deep pond of

CSG water.

To minimise bypass flow along the wall of the permeameter

under the high applied hydraulic gradient of 200, a well-graded

sand was glued to the wall to roughen its surface. The

effectiveness of the sand coating in preventing bypass flow was

verified by conducting hydraulic conductivity tests under a

100 kPa constant water pressure using CW applied to SB1

mixed with CW and compacted to 90% of the MDD at OMC,

and 95% of MDD wet of OMC. A 101.9 mm diameter by 5 mm

thick sharp-edged divider ring was installed centrally on top of

the base plate, on which a 3 mm thick medium sand layer was

placed to act as a drainage layer. The divider ring had an area of

about 50% of the open permeameter area and penetrated about

2 mm into the base of the compacted clay specimen. In addition

to an outlet located at the centre of the base plate, two outer

outlets between the permeameter wall and the edge of divider

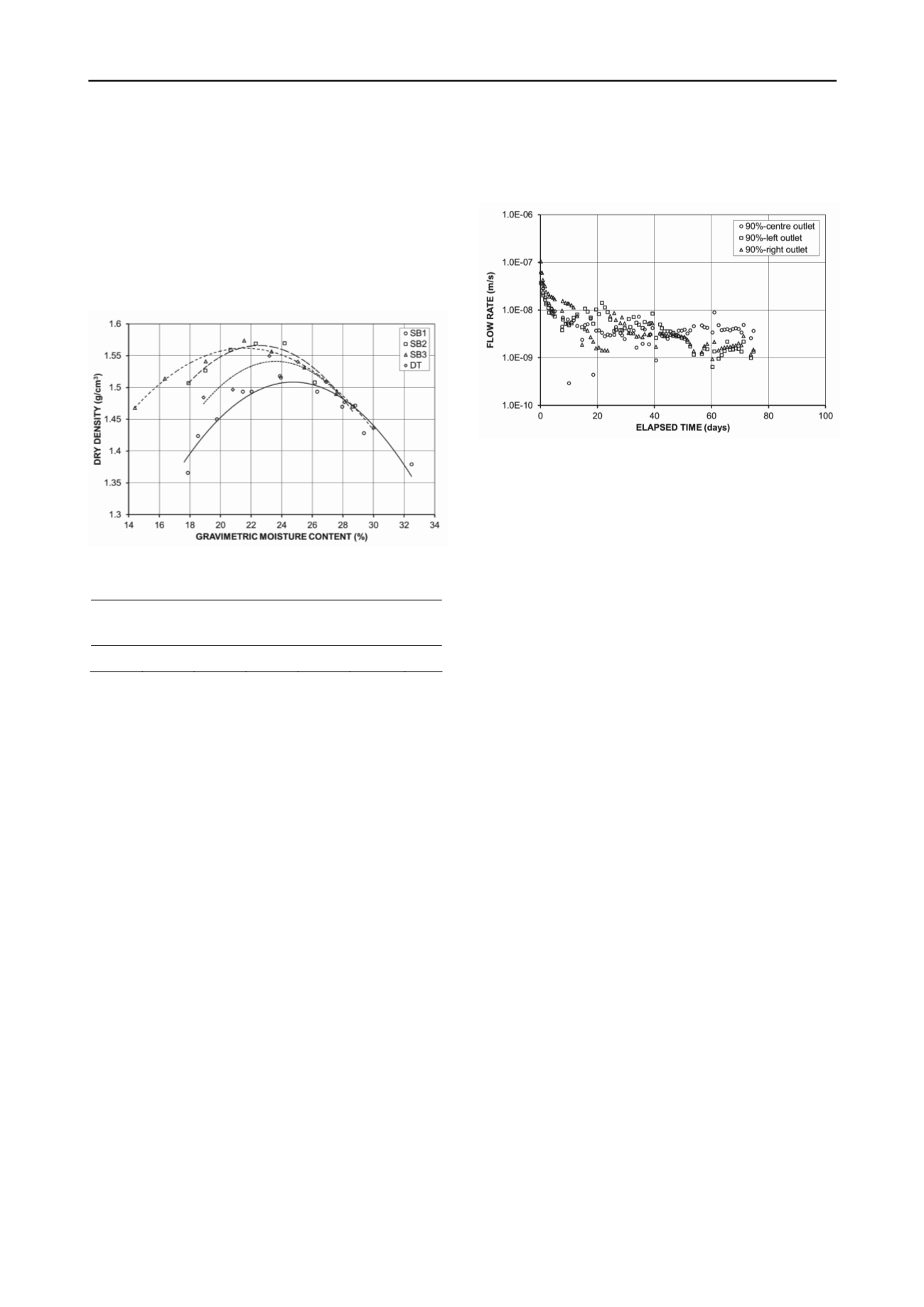

ring were provided. The flow rates from each of the outlets were

calculated assuming vertical only flow. The measured flow rates

from each of the outlets for the 90% MDD at OMC specimen

are shown in Figure 2, in which there are no appreciable

differences between the central and outer flow rates, indicating

that the roughened permeameter wall was effective in

minimising bypass flow. A similar result was obtained for the

95% MDD wet of OMC specimen.

Figure 2. Flow rates from centre and outer outlets during testing of 90%

MDD at OMC specimen with roughened permeameter wall.

A set of hydraulic conductivity tests was conducted on SB3

compacted to 90% of the MDD at the OMC, 95% of MDD at

OMC and wet of OMC, 98% of MDD at OMC and wet of

OMC, and 100% of MDD at OMC, to study the effects of dry

density and moulding moisture content on hydraulic

conductivity. Another set of hydraulic conductivity tests was

conducted on all samples compacted to 95% of MDD wet of

OMC, and mixed and permeated with DW and CW, to

investigate the effects of moulding and permeating water type

on hydraulic conductivity. These dry densities and moisture

contents were selected because the clays in the field are usually

compacted to 95% of MDD wet of OMC.

It was expected that moisture conditioning wet of the OMC

would show significant differences in the compacted hydraulic

conductivity compared to that following moisture conditioning

to the OMC, since additional water would be available to fill the

initially air-dried voids. The permeameter tests were terminated

once a relatively constant flow rate and salt concentration of the

outflow had been achieved. The EC and pH values of the

outflows were measured using a portable EC-pH meter, while

concentrations of major anions (Cl

-

) and cations (Na

+

, Mg

2+

,

Ca

2+

and K

+

) were measured using inductively-coupled plasma

and inductively-coupled plasma-optical emission spectrometry

methods, respectively.

3.2

Oedometer testing

Oedometer tests were conducted on standard 76 mm diameter

by 20 mm thick compacted specimens mixed with and in a

water bath of CW or DW. Each specimen was subjected to

incremental applied stresses of 10 kPa, 50 kPa, 100 kPa and

150 kPa, from which data the coefficients of consolidation and

coefficients of volume decrease, and hence hydraulic

conductivities, were calculated. During the tests, the oedometer

cells were covered with Glad wrap to prevent any change in the

salt concentration or pH of the water bath due to evaporation.

4 TEST RESULTS AND DISCUSSION

4.1

Compaction mould hydraulic conductivity

The measured hydraulic conductivities of all compacted SB3

specimens are shown in Figure 3. Figure 3 shows that

specimens compacted to 90% of MDD at OMC tend to have the

highest hydraulic conductivities, while specimens compacted to

100% of MDD at OMC and 98% of MDD wet of OMC tend to

have the lowest hydraulic conductivities. Comparing the data

for specimens compacted at 98% and 95% of MDD, it appears