3027

Technical Committee 215 /

Comité technique 215

Table 2. Model parameters for drying branches

Parameter WN2 NN1 NN1-20 WNT

a

f

1

358 339

91.3

355

m

f

1

0.678 0.626

0.93

2.01

n

f

1

4.72

5.78

2.23 0.819

S

1

2

15.5 0.974

6.86

15.4

S

2

2

134 114

152 88.1

S

3

2

11.5

13.5

8.74

8.76

ae

3

(kPa)

176 137

46.5

63

r

3

(kPa)

1620 1600

650

5220

1

Fredlund and Xing (1994)

2

Pham and Fredlund (2008)

3

Based on Fredlund and Xing (1994)

Table 3. Model parameters for wetting branches

Parameter WN2 NN1 NN1-20 WNT

a

f

1

218 210

203 100000

m

f

1

1.03

2.19

1.28

11.9

n

f

1

1.28 0.695

1.29

0.368

S

1

2

25.1

21.7

29.6

43.2

S

2

2

74.8

72.2

101

115

S

3

2

8.72

8.12

10.3

6.47

ae

3

(kPa)

78 30.3

66.9

125

r

3

(kPa)

8960 4250

2260 25000

1

Fredlund and Xing (1994)

2

Pham and Fredlund (2008)

3

Based on Fredlund and Xing (1994)

The general shape and trends for the GCL moisture-suction

relationships for the tested GCLs were similar to soils with

discernable air entry and residual moisture characteristics and

hysteresis observed between drying and wetting curves. The

moisture-suction characteristics of as-received WN2 and NN1

were relatively similar, whereas the air entry suction value for

the WNT specimens were lower than WN2 and NN1 for drying

(Table 2) and higher for wetting (Table 3). Residual suction

values for WNT were higher than those for WN2 and NN1

(Tables 2 and 3).

The extent of hysteresis observed for WNT was higher than

that for WN2 and NN1. The similar moisture-suction

relationships of WN2 and NN1 were attributed to the relatively

similar structures of the GCLs. The presence of the geofilm

impacted the response of WNT in line with the observations of

Beddoe et al. (2011) indicating effects of GCL structure on

material behavior.

Hysteresis observed in the tests was quantified for selected

moisture levels for GCLs representing as-received/as-placed,

common field exhumed, and limiting air entry and residual

conditions for NN1 using as-received and wet-dry cycled

conditions (Table 4). Wetting and drying cycles affected

moisture-suction behavior of NN1 (Figures 2 and 4 and Tables

2-4). For drying, air entry and residual suctions decreased with

cycling and for wetting, the opposite trend was observed

(increasing air entry and residual suctions with cycling). The

extent of hysteresis decreased (i.e., less difference between

drying and wetting curves) in response to cycling (Table 4). The

limited level of hysteresis observed for cycled specimens was

consistent with findings reported by Fredlund et al. (2012)

indicating that laboratory water retention tests provide extreme

trends (i.e., bounds of limiting envelope) for wetting and drying

branches of soil water characteristic curves (SWCCs), whereas

in-situ soils are expected to demonstrate less extreme trends

bound within the envelope. The GCL data were observed to be

similar, in that data for the cycled GCLs representing in-service

conditions were generally inside the limiting envelope.

Table 4. Extent of hysteresis between wetting and drying branches

Conditioning Suction

Wetting

Curve

(kPa)

Drying

Curve

(kPa)

Hysteresis

(kPa)

r

4245

1602

266

w=50%

1215

1711

496

w=75%

521

829

308

w=100%

249

591

342

w=125%

118

480

362

No cycles

ae

30.3

137

107

r

2260

650

769

w=50%

1170

815

356

w=75%

577

386

191

w=100%

330

247

83

w=125%

190

178

12

20 cycles

ae

66.9

46.5

55

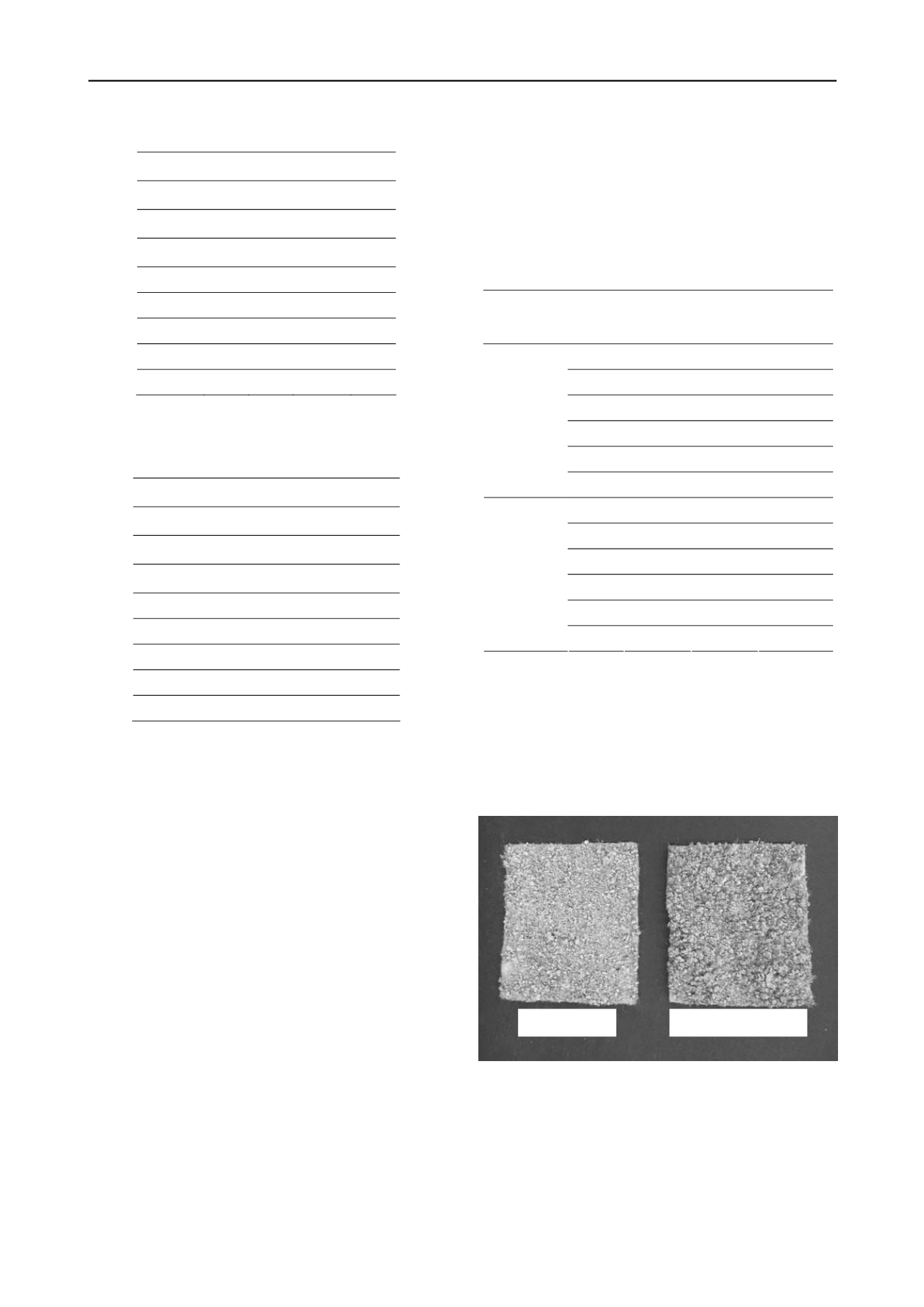

Both macroscopic and microscopic changes occurred in the

bentonite due to wet-dry cycling. On a macroscale, the

agglomerated particles (i.e., granules) became larger in response

to cycling. Grain size distributions of the granules were

determined for as-received and cycled conditions. The percent

retained on a No. 10 (2.0 mm) sieve for the cycled specimens

was 10% greater than the percent retained for the as-received

specimens. A photograph of the exposed bentonite component

for as-received and cycled conditions is presented in Figure 5.

Figure 5 Photograph of exposed bentonite component of the GCLs.

As-Received

20 Wet-Dry Cycles

Selected SEM images of bentonite from GCLs at varying

stages of wet-dry cycles are presented in Figure 6. All images

are presented using the same scale. Variation in the

microstructure of the bentonite was observed in the images. The

baseline (i.e., dispersed fabric) image for bentonite saturated

with DI water (Figure 6a) is consistent with microscopic

analysis of pulverized montmorillonite presented by Egloffstein

(2001). The bentonite became progressively less oriented and

more random with increasing wet-dry cycles. Spaces between

particle agglomerations became visible, in particular for the