2627

Technical Committee 211 /

Comité technique 211

of the bridge embankments) is considered substantial, while its

secondary effects such as the acceleration of consolidation at

layers that were found under-consolidated and the reduction of

downdrag forces at piles (i.e. by allowing the consolidating soil

to settle before construction) increase its efficiency. The

prescribed pre-loading embankment were wider from the bridge

embankment / pile cap by 2.5-3.0m at each side, in order to

apply uniform stress at the area of interest, while its height

generally varies between 3 and 7m.

Stage construction of pre-loading embankment was decided

(with height increments between 1.5-2.0m), due to the poor soil

conditions, followed by continuous settlement and pore-

pressure dissipation recordings. Figure 2 presents the

anticipated final (after improvement) distribution of S

u

with

depth for the CPT recording presented in Section 3.

Gravel pile installment is prescribed ahead of pre-loading,

consisting of 0.80m diameter piles in a 1.80 x 1.80m square

arrangement (denoting replacement percentage equal to a

s

=

0.78x (0.8/1.8)

2

=15.4%). Gravel pile length varies between 8

and 13m, depending on soil conditions.

The installation of gravel piles increased the mechanical

properties of the upper cohesive fine-grained layers and

subsequently increased the general stability of bridge & pre-

loading embankments. The following equivalent strength

parameters were used (Van Impe & De Beer, 1983):

c

eq

= (1-a

s

) S

u,f

(4a)

tanφ

eq

= [na

s

/(na

s

+1 –a

s

)]tanφ

1

(4b)

where

c

eq

& φ

eq

denote the equivalent cohesion & friction angle

of the composite system respectively,

φ

1

denotes the friction

angle of gravels (assumed equal to 42

o

),

a

s

denotes the

replacement ratio (equal to 0.154) and

n

denotes the ratio of the

load taken by the gravel pile versus the surcharge load. The

contribution of geostatic stresses is omitted; while outside the

embankment limits (where no surcharge is applied)

n

equals

1.0. The improved shear strength of the composite system,

combined with the increase of the undrained shear strength due

to pre-loading proved adequate for the construction of the

bridge embankments with acceptable factor of safety under both

static and seismic conditions (e.g. the static F.S. increased from

0.64 to 1.51 for a representative height of 4m).

Note that, besides the improvement of shear strength

characteristics, the inclusion of gravel columns combined with

pre-loading has altered the seismic ground response relative to

free-field. In order to take into account this effect, the shear

wave velocity and the spring stiffness in P-y curves of the

relevant soil layers were appropriately increased. Namely, the

formula presented by Baez & Martin (1993) was used for the

estimation of the maximum shear modulus of the composite

system:

G

max,eq

= G

max,i

a

s

+ G

max,p

(1-a

s

)

(5)

where

G

max,eq

is the maximum equivalent shear modulus,

G

max,i

is the maximum shear modulus of the fine-grained layer after

pre-loading,

G

max,p

is the maximum shear modulus of the gravel

pile and

a

s

is the replacement ratio (here 0.154). The maximum

shear modulus of the fine-grained layer after pre-loading was

computed as follows (Weiler, 1988):

G

max,i

= G

max,o

OCR

0.5

(6)

where G

max,o

is the maximum shear modulus of unimproved

soil, as computed by Eq. 2. The maximum shear modulus of the

gravel pile was computed assuming a dense configuration

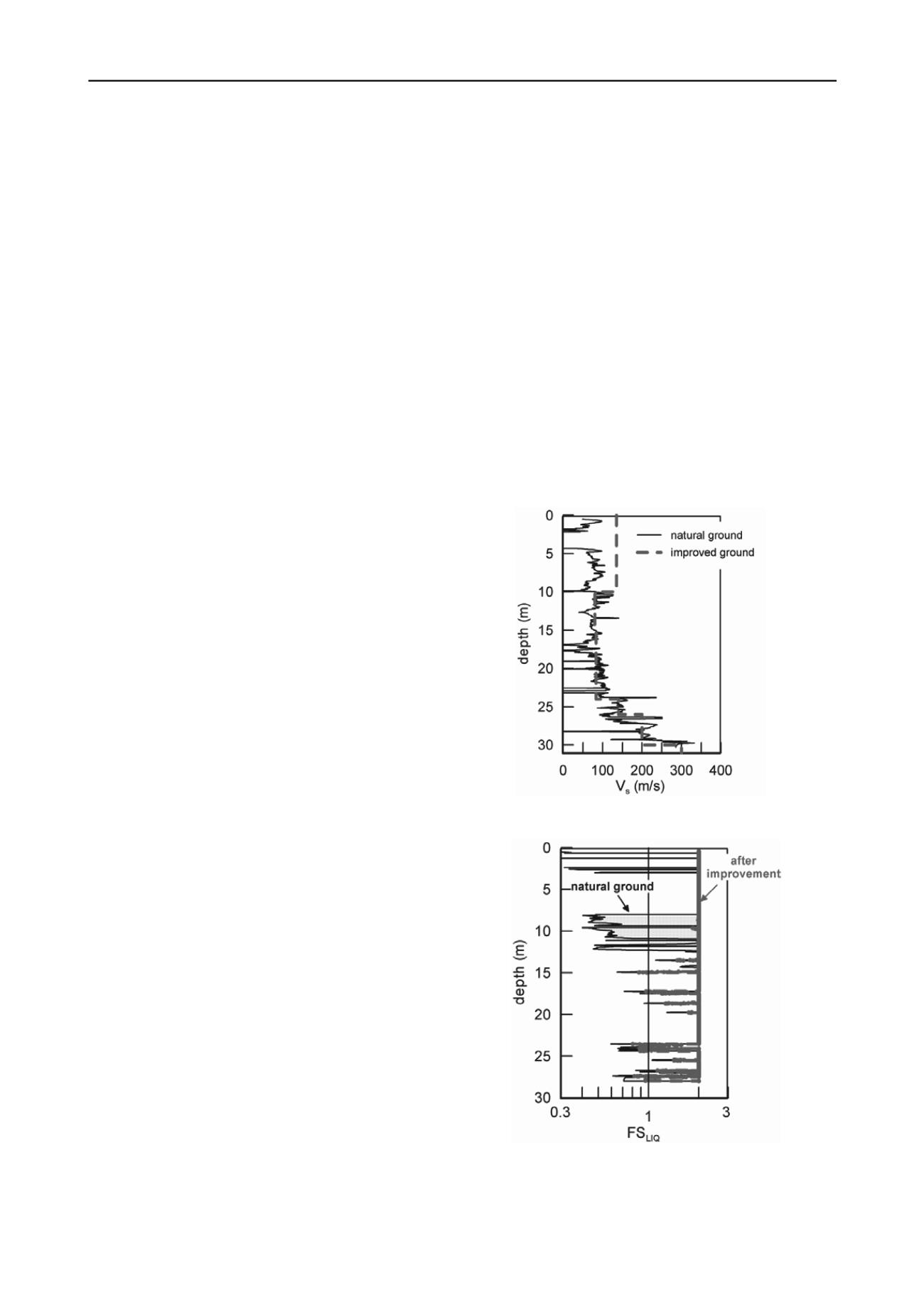

(e=0.55). Figure 3 presents the shear wave velocity profile of

the composite system for the CPT recording of Fig. 1. The

average shear wave velocity V

s,30

for this profile increased from

86 to 140m/s, reflecting stiffer ground conditions. This increase

was also implemented to the P-y curves, by increasing the

horizontal subgrade reaction coefficient k. The increase was

assumed proportional to the ratio G

max,eq

/G

max,o

, while for the

unimproved soil coefficient k was computed according to

DIN4014 for bored cast-in-place piles.

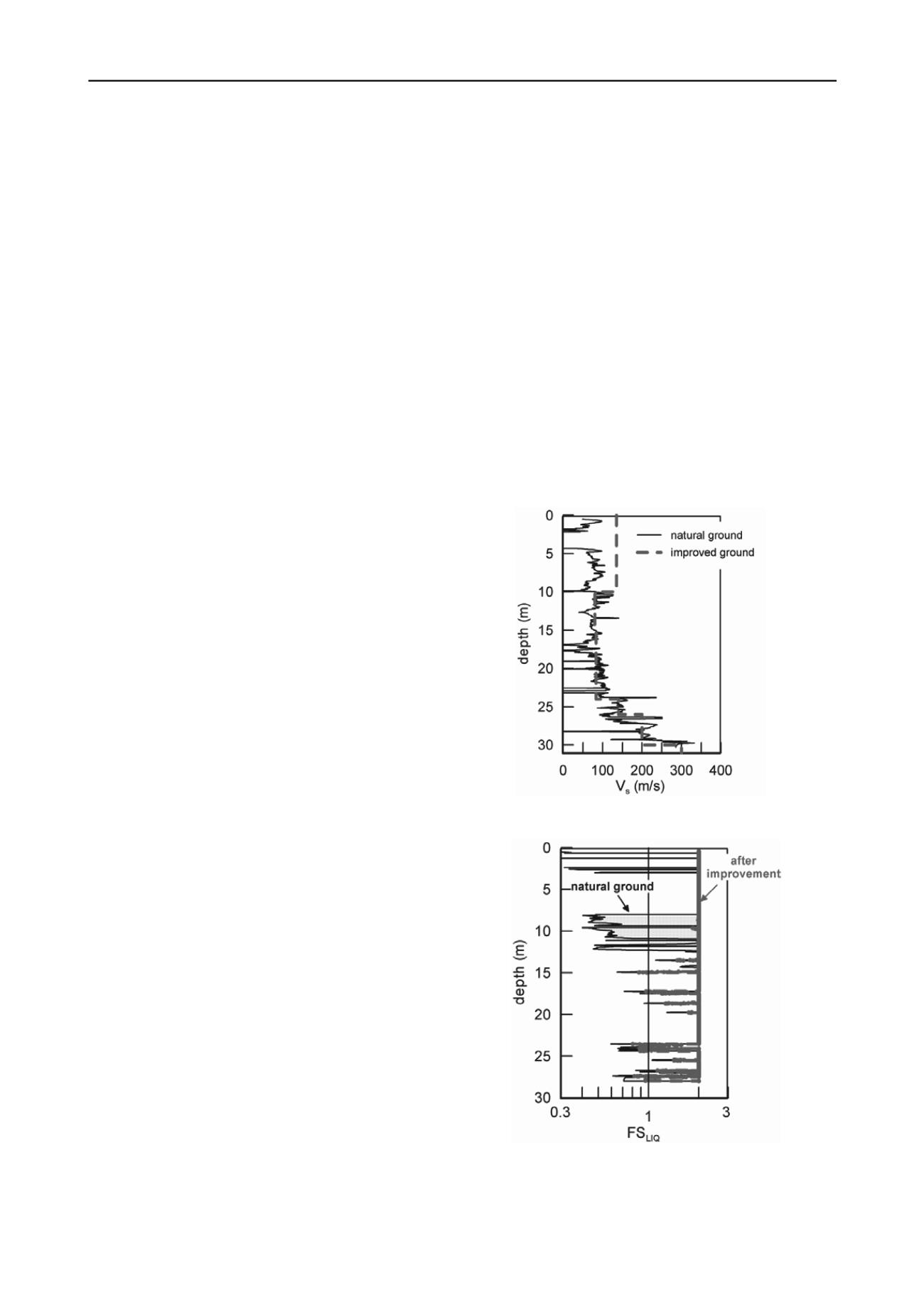

For the case of Profile II, where a non-cohesive liquefiable

layer is present, the gravel piles are expected to act as a

countermeasure against liquefaction. The gravel piles will be

constructed via bottom-feed vibro-replacement, while a proper

gradation curve range is prescribed in order to ensure the

effective drainage of earthquake-induced excess pore-pressures.

During vibro-replacement, the non-cohesive layer is expected to

be densified and increase its resistance to liquefaction. Based on

Mizuno et al. (1987), the average measured tip resistance is

expected to increase between gravel piles from 4.5MPa to

9.5MPa, providing an adequate liquefaction resistance. Figure 4

compares results from the preliminary (before improvement)

and the detailed (after ground improvement) liquefaction study,

which show the minimization of liquefaction potential. The

densification of the non-cohesive layer due to pre-loading and

the potential dissipation of excess pore pressures were

conservatively ignored. It is noted that even if densification was

ignored, drainage through gravel piles would retain excess pore

pressure ratio r

u

well below 0.5, as computed according to Seed

& Booker (1977) and Bouckovalas et al. (2011) for the given

characteristics and gravel pile geometry.

Figure 3: Distribution of shear wave velocity with depth for profile I,

before and after the improvement

Figure 4: Factor of safety against liquefaction for Profile II, before

(preliminary results) and after improvement (detailed study).

Finally, consolidation process is expected to be accelerated with

the presence of gravel piles. Excess pore pressures for each

loading stage are expected to diminish within 19 days, assuming

conservatively only radial flow towards the gravel piles and