2618

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

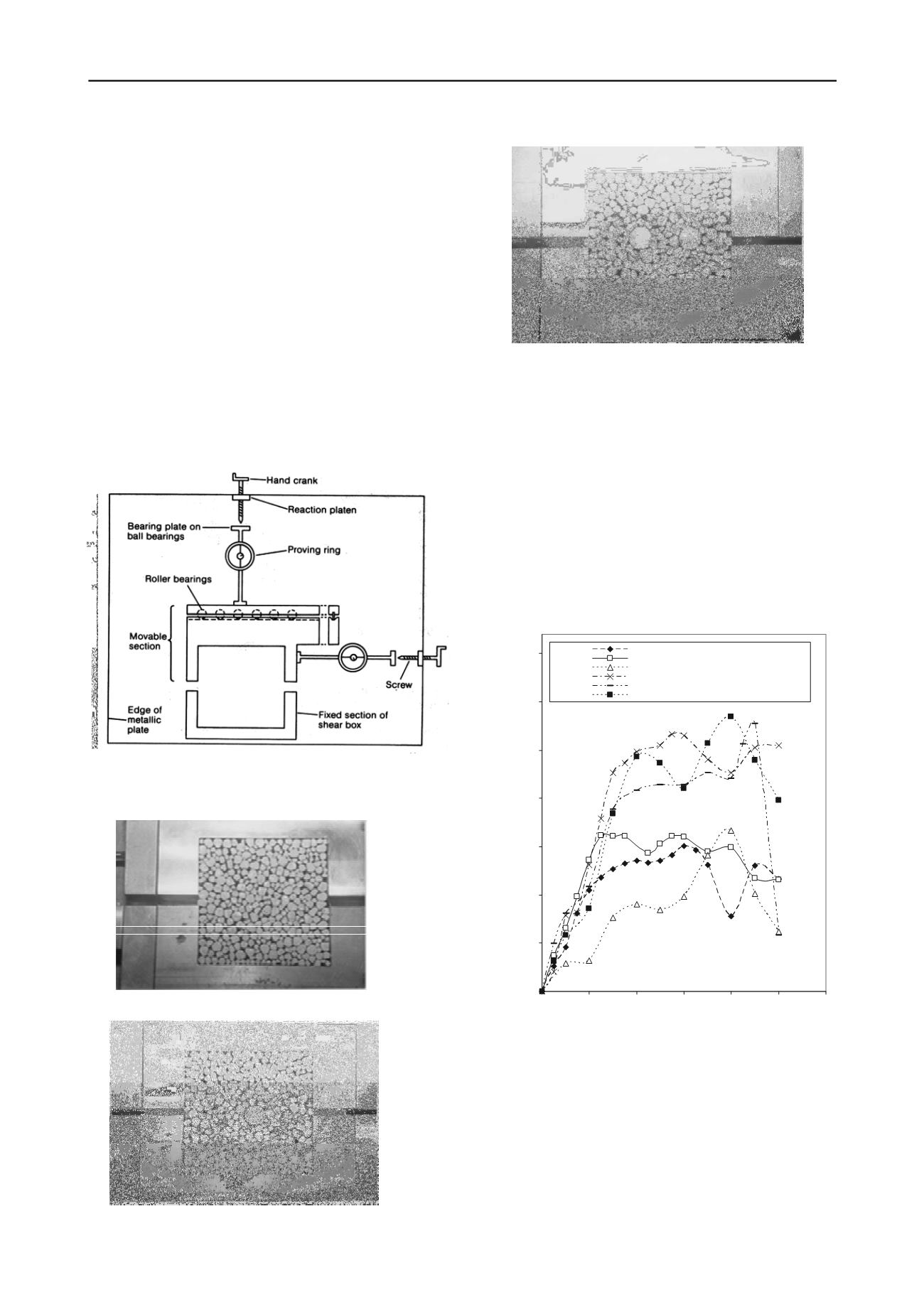

granular materials (Fig. 3) .The wooden sticks forming the

granular matrix will have 3 different average diameters. These

will be equal of 6, 4, and 2.7 mm. Thus, thegranular matrix as a

whole will be made of sticks having an average diameter equal

to 4.2 mm. The oversized large particles will be simulated by

rough wooden circular cylinders with a diameter equal to 12

mm. The irregular sticks as well as the circular cylinders have a

length equal to 25 mm. The mixture of wooden sticks and

cylinders were placed inside two U forms that comprise the box

in the Plane Stress Direct Shear apparatus (PSDSA)( Figs. 2 and

3). The area inside the two U forms is a square area with sides

measuring 7.6 cm in length. The open face of the shear

apparatus formed by the two U forms allows the recording of

the changes taken place in the mixture during shearing. Two

proving rings measure the normal and shear forces applied to

the mixtures. Dial gauges measure the normal and shear

displacements. The changes in fabric experienced by the

mixture as well as the interaction between the granular matrix

and the large particles during shear was recorded using digital

photographs of the open face of the PSDSA .

Figure 2. The Plane Stress Direct Shear Apparatus (PSDSA)

(Vallejo, 1991)

(a)

(b)

(c)

Figure 3. Simulated granular mixture in the PSDSA before shearing: (a)

sample with no oversized particles, (b) sample with one oversized

particle, (c) sample with two oversized particles.

2.2

Direct shear testing in the PSDSA

The simulated granular mixtures depicted in Fig. 3 were

subjected to shear in the PSDSA. The shear testing of the

mixtures were carried out using two normal stresses. These

were equal to 99.6 and 199.3 kPa. The rate of shearing of the

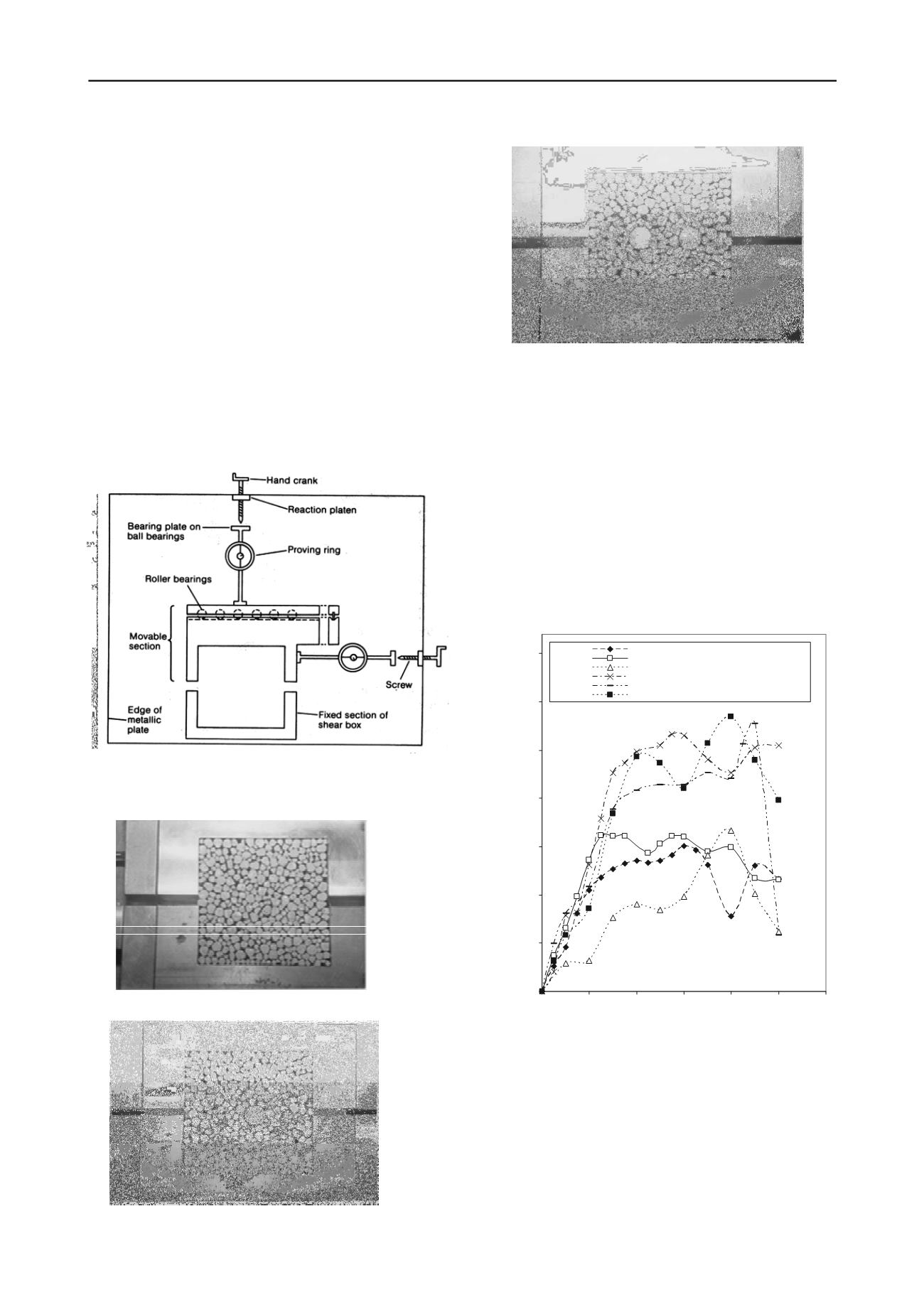

mixtures was equal to 2mm/min. Fig. 4 shows the shear stress

versus the horizontal displacement relationships for the sample

containing the matrix alone and the samples with one and two

12 mm in diameter cylinders representing the large particles

(Fig.3).

Figure 4. Shear stress versus horizontal displacement for the samples

tested in the PSDSA

The peak values of the shear stress plots of Fig. 4 have been

used to plot the shear strength versus the area concentration of

the large cylinders in the sample. This area concentration is

equal to the cross sectional area of the large cylinders in the

mixture divided by the area of the whole mixture (7.62 cm x

7.62 cm) (Fig. 3). The resulting plot is shown in Fig. 5. This

figure shows that the shear strength of the mixture increases as

the number of large cylinders increases in the mixture. An

equation that represents this increase is of the form:

0

50

100

150

200

250

300

350

0

0.02

0.04

0.06

0.08

0.1

0.12

Horizontal displacement (cm)

Shear stress (kPa)

Matrix (99.6kPa)

One oversized particle (99.6kPa)

Two oversized particles (99.6 kPa)

Matrix (199.3 kPa)

One oversized particle (199.3 kPa)

Two oversized particles (199.3kPa)

granular matrix will have 3 diff rent average diam ters. Th se

will b equal of 6, 4, and 2.7 m. Thus, thegranular matrix as a

whole will be made of sticks having an average diam ter equal

to 4.2 m. The oversized large particles will be simulated by

rough wooden circular cylinders with a diam ter equal to 12

m. The irregular sticks as well as the circular cylinders have a

length equal to 25 m. The mixture of wooden sticks and

cylinders w re placed inside two U forms that comprise the box

in the Plane Stress Direct Shear app ratus (PSDSA)( Figs. 2 and

3). The area inside the two U forms is a square area with sides

measuring 7.6 cm in length. The open face of the shear

app ratus formed by the two U forms allows the recording of

the changes taken place in the mixture during shearing. Two

proving rings measure the normal and shear forces applied to

the mixtures. Dial gauges measure the normal and shear

displacements. The changes in fabric experienced by the

mixture as well as the interaction between the granular matrix

and the large particles during shear was recor ed using d gital

ph tographs of the open face of the PSDSA .

Figure 2. The Plane Stress Direct Shear App ratus (PSDSA)

(Vallejo, 1991)

(a)

(b)

(c)

Figure 3. Simulated granular mixture in the PSDSA before shearing: (a)

sample with no oversized particles, (b) sample with one oversized

particle, (c) sampl with two oversized particles.

2.2

Direct shear testing in the PSDSA

The simulated granular mixtures depicted in Fig. 3 were

subjected to she r in the PSDSA. Th shear testing of the

mixtures wer carried out using two normal stresses. T se

were equal to 99.6 and 199.3 kPa. The ate of shearing of the

mixtures was equ l to 2mm/min Fig. 4 sh w the shear str ss

versu the horizon al displacement relationships for the ample

containing the m trix alon and th samples with one nd two

12 mm in diameter cylinders representing the large particles

(Fig.3).

0

50

100

150

200

250

300

350

0

0.02

0.04

0.06

0.08

0.1

0.12

Horizontal displacement (cm)

Shear stress (kPa)

Matrix (99.6kPa)

One oversized particle (99.6kPa)

Two oversized particles (99.6 kPa)

Matrix (199.3 kPa)

One oversized particle (199.3 kPa)

Two oversized particles (199.3kPa)

Figure 4. Shear stress versus horizontal displacement for the samples

test d in t PSDSA

The peak values of the shear stress plots of Fig. 4 have been

used to plot the shear tr ngth versus he area concentration of

the large cylind rs in the sample. This area concentration is

qual to the cro s section l ar a of the large cyli ders in the

mixture divided by he re of the whole mixture (7.62 cm x

7.62 cm) (Fig. 3). The resulting plot is shown in Fig. 5. This

figure shows that t shear strength of t e mixture increases as

the number of large cylinders increases n the mixture. An

quation that rep esents this increas i of the for :

S

c

= S

m

(1 + 2C

a

) (1)