2614

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2.2

Curing method (nutrient injection process)

After saturation, 250 ml of microbial broth was injected into

each specimen. The microbial broth was made by planting

Sporosarcina pasteurii

in the medium described in Table 2.

After confirming that the broth had completely permeated the

specimen, 200 ml of the nutrient mixture described in Table 3

was injected into the specimen at 12 h intervals for specified

cycles.

Table 1. Physical properties of Toyoura sand

Soil

particle

density

s

(g/cm

3

)

Water

content

(%)

Max.

grain

diameter

(mm)

50%

diameter

on the

grain

size

diagram

D

50

(mm)

Fine

fraction

content

(%)

Max.

dry

density

d

max

(g/cm

3

)

Min.

dry

density

d

min

(g/cm

3

)

Soil

suspension

pH

2.623 0.0 0.425 0.177 0.6 1.645 1.333 6.3

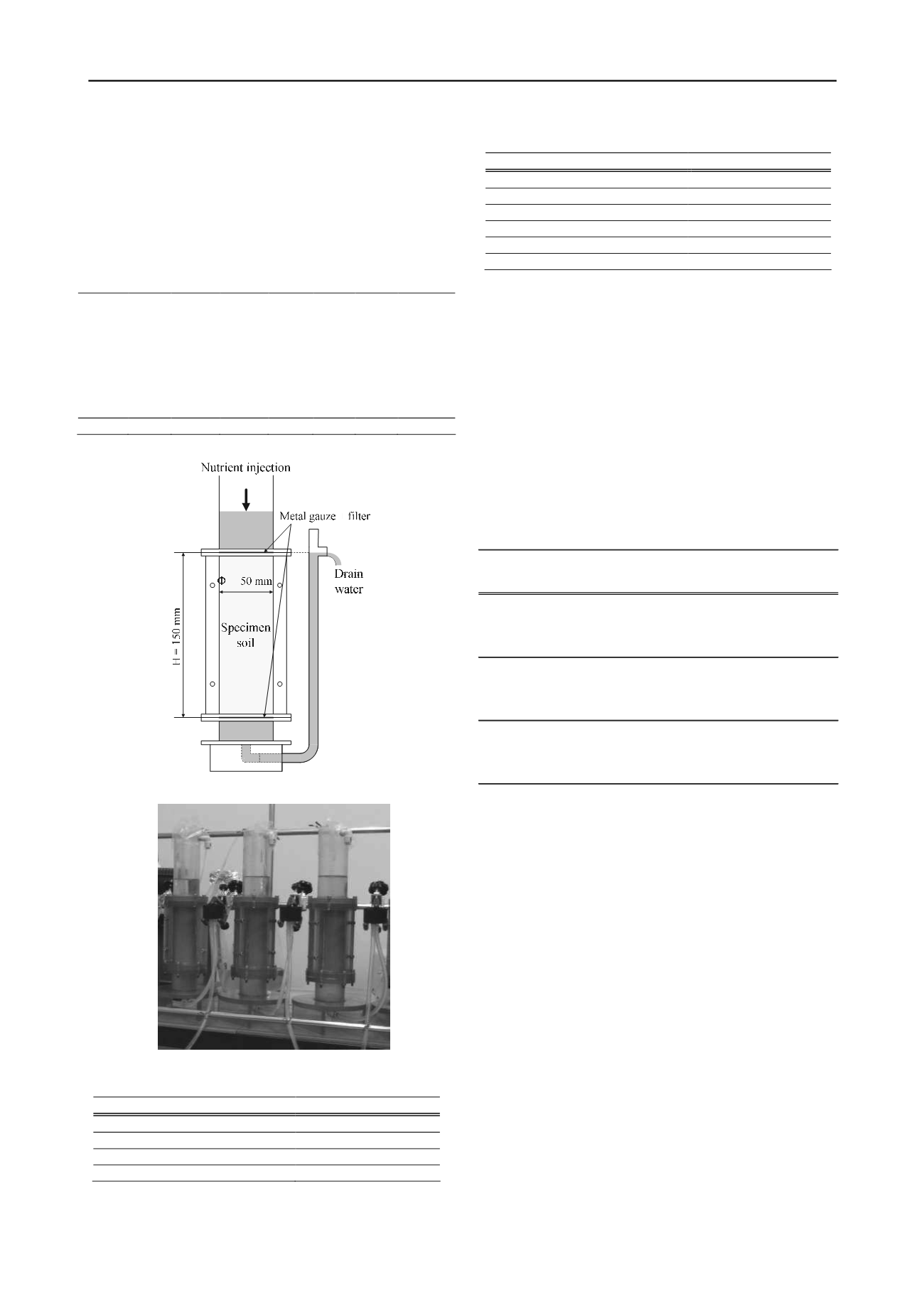

Figure 1. Schematic diagram of the mold

Photo 1. Photo of the mold

Table 2. Composition of medium

Name of reagent

Added amount

0.13 M Tris (pH = 9)

0.13 mol = 15.75 g

Yeast extract

20 g

(NH4)

2

SO

4

10 g

Distilled water

1 L

Table 3. Composition of nutrient mixture

Name of reagent

Added amount

Nutrient broth

3 g

NH

4

Cl

10 g

NaHCO

3

2.12 g

Urea

0.5 mol = 30.03 g

CaCl

2

0.5 mol = 55.49 g

Distilled water

1 L

The mold was cured in a room with a constant temperature

set at 22°C. The nutrient mixture that had been injected

previously and that remained in the pore was pushed out and

drained to maintain the saturated state of the specimen in the

mold.

Approximately 12 h after the specified cycles of nutrient

injection were completed, 300 ml of distilled water was injected

to wash away the nutrient mixture remaining in the pore.

As Table 4 shows, 15 specimens were made. The nutrient

mixture was injected into these specimens at various

frequencies in order to diversify the amount of CaCO

3

precipitation at each relative density. In addition, three

specimens were only saturated with distilled water, and not

injected with the broth and nutrient mixture, in order to examine

the strength of the Toyoura sand itself.

Table 4. Test cases

Initial dry

density

Initial

relative

density

CaCO

3

Precipitation

• •

d

(g/cm

3

)

Dr (%)

(kg/m

3

)

Dr30-N

―

―

1.423

33.2

―

Dr30-P1

2(400)

24

1.428

35.2

32.24

Dr30-P2

4(800)

48

1.414

30.2

63.72

Dr30-P3

8(1600)

96

1.416

30.8

141.92

Dr30-P4

12(2400)

144

1.414

30.4

225.53

Dr60-N

―

―

1.513

62.6

―

Dr60-P1

2(400)

24

1.504

59.9

28.11

Dr60-P2

4(800)

48

1.504

60.0

51.77

Dr60-P3

8(1600)

96

1.504

59.9

130.61

Dr60-P4

12(2400)

144

1.504

60.0

212.11

Dr85-N

―

―

1.589

84.9

―

Dr85-P1

2(400)

24

1.589

85.0

27.12

Dr85-P2

4(800)

48

1.589

85.0

57.38

Dr85-P3

8(1600)

96

1.589

84.9

117.13

Dr85-P4

12(2400)

144

1.589

85.0

198.55

Dr60

Dr85

Case Specimen

No.

Dr30

Frequency of

nutrient injection

(Total injection

amount ml)

Curing

time

(hours)

2.3

Triaxial test method

Triaxial tests (CD condition) were conducted using the

specimens produced by the method explained in 2.2. To reduce

disturbance caused by the demolding/shaping of specimens, the

specimens were frozen in the mold after the free water was

removed. The specimens that featured high CaCO

3

precipitation

were also frozen to equalize test conditions. The frozen

specimens were removed from the molds and shaped to 10 cm

in height and 5 cm in diameter. The shaped specimens were

measured to check the diameter and height and then placed in a

triaxial cell and defrosted under a negative pressure of 30 kPa.

The defrosting time was set at about 1.5 h, which was the

approximate time needed for stabilization of the axis

displacement caused by contraction in the process of defrosting.

We measured the diameter and the height of the defrosted

specimens, covered them with a cell cover, and saturated them

with degassed distilled water via the double-negative pressure

method. The back pressure was increased to 200 kPa, and

effective consolidation stresses of

c

’

= 100 kPa were applied

for isotropic consolidation. After consolidation, we confirmed

that the

B

values in all the specimens were 0.95 or higher. Then,

axial compression was performed at a strain rate of 0.5%/min.

The axial force was measured by the load cell inside the cell,

axial strain was measured by the displacement gauge outside the

cell, cell pressure and back pressure were measured by the

water pressure gauge, and the volume change was measured by

the low-capacity differential pressure gauge.