2619

Technical Committee 211 /

Comité technique 211

S

c

= S

m

(1 + 2C

a

)

(1)

where S

c

is the shear strength of the mixture, S

m

is the shear

strength of the matrix, and C

a

is the area concentration of the

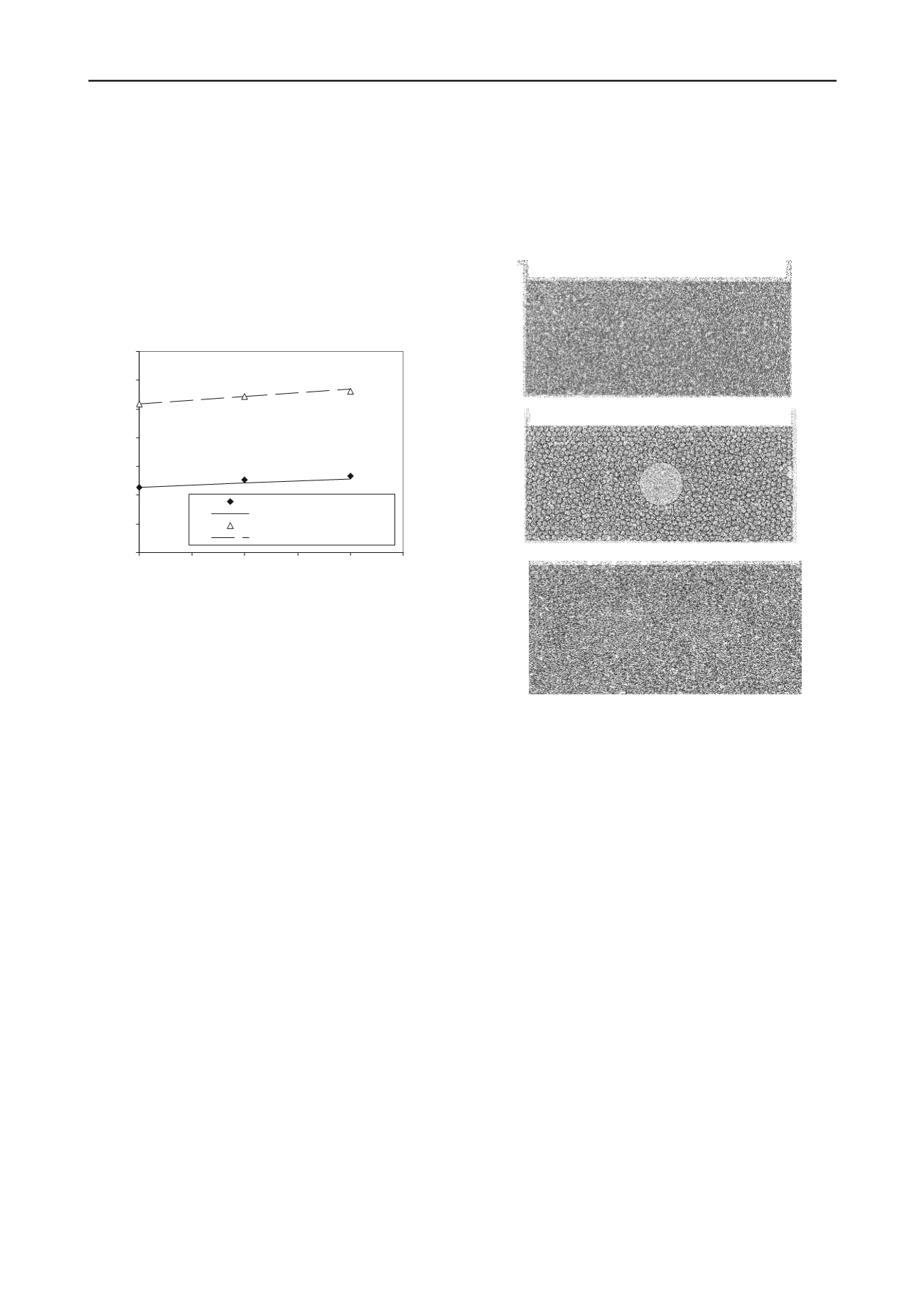

large cylinders in the mixture. The results of Fig. 5 and Eq. (1)

indicate that the overall shear strength of the simulated granular

mixtures increases with an increase in the number of the large

cylinders. Thus, in the case of real sand-gravel mixtures, it is

expected that the shear strength of these mixtures will increase

with the volume concentration of the gravel in the mixtures.

Figure 5.Shear strength of the simulated granular mixtures in function

of the area concentration of the large cylinders in the mixture.

3 ANALYSIS OF THE LABORATIRY RESULTS USING

THE DISCRETE ELEMENT METHOD (DEM)

3.1 Configuration of the samples

The PFC

2D

program produced by Itasca (Itasca Consulting

Group Inc., 2002) was used for the simulation of the direct

shear tests on granular material with dispersed oversized

particles. The first step on the configuration of the sample was

the construction of the shear box. The box had two sections

each with a width of 6 cm and a height of 1.5 cm. The two

sections were placed on top of each other and after the circular

particles were generated inside the box, the gap between the two

sections was maintained at 0.5 mm. The depth of the sample

was assumed to be equal to 1 m. The shear and normal stiffness

of the walls forming the box were set to 1x10

9

N/m. The

coefficient of friction between the circular particles and the

particles and the walls was set to 0.7.

After the construction of the box, 1000 particles representing

the granular matrix and having a diameter of 0.63 mm were

generated inside the box. The density of the particles was set to

2,500 kg/m

3

, their normal and shear stiffness were set to 1x10

8

N/m. Their positions were randomly chosen by the program,

having the limitation of no overlap between particles. A normal

gravity field (9.8 cm/sec

2

) was used during the simulation. In

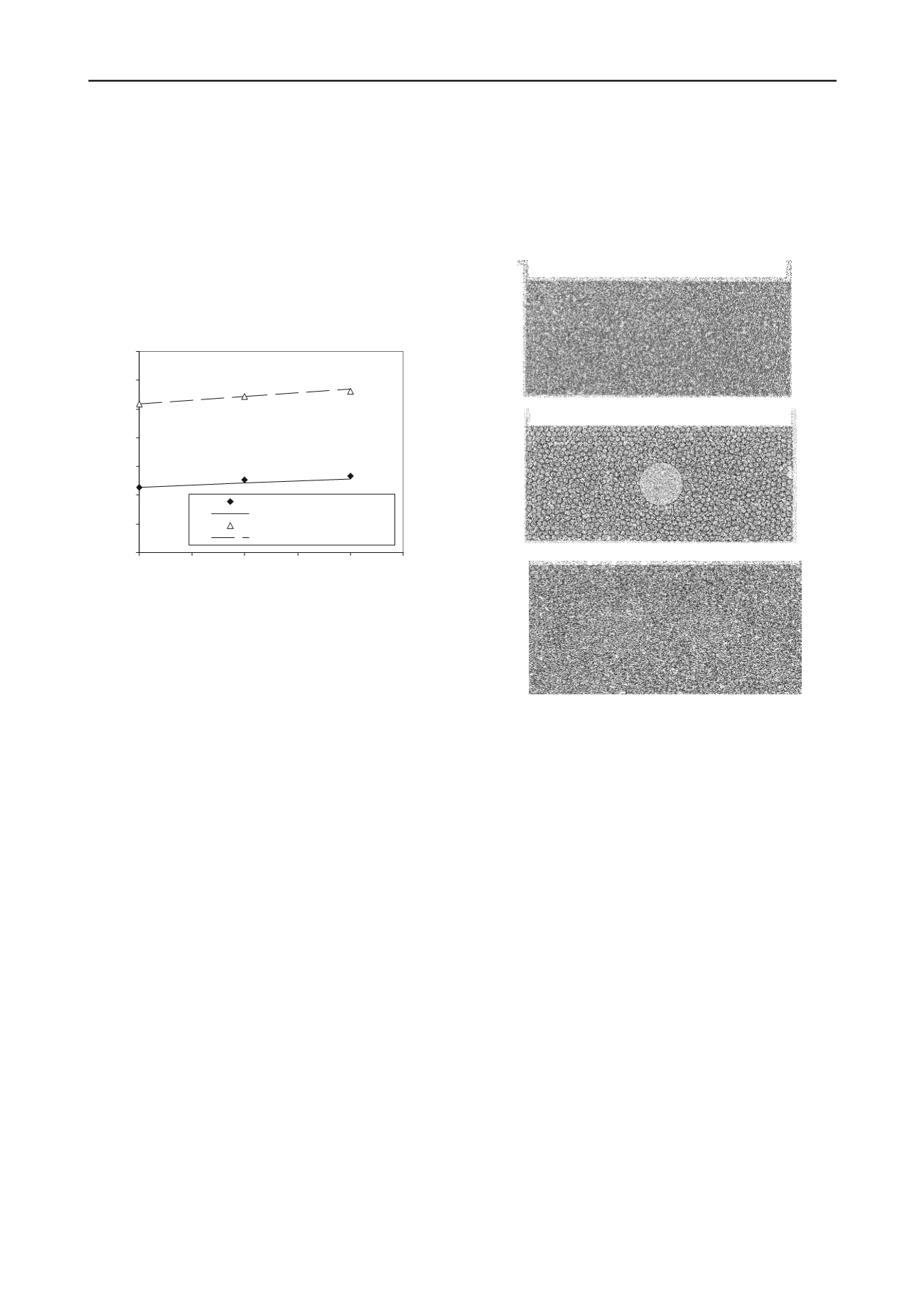

order to simulate the dispersed oversized particles, 52 particles

of diameter equal to 0.63 mm were removed and replaced by an

oversize particle measuring 5 mm. If an additional oversize

particle was needed to be placed in the sample, the same

number of smaller particles were removed and replaced by

another large particle of 5 mm in diameter (Fig. 6). The tests

were run under a constant normal compressive load equal to

2x10

4

N. After the normal compressive force was applied to the

sample, the shearing started by moving the upper section of the

shear box to the left with a constant velocity of 0.44 mm/sec.

The tests ended when the horizontal displacement was equal to

5 mm. Also, using a subroutine available in the PFC

2D

code, one

can obtain the value of the shear stress in function of the

horizontal deformation. In this study, the peak shear resistance

that was measured in the simulationrepresents the shear strength

of the mixture.

Figure 6. Simulated samples using DEM that contained zero, one, and

two large dispersed particles.

3.2 Results of the simulations

The DEM simulations of the direct shear tests were carried out

on mixtures having zero, one, and two oversized particles. Figs

7 shows typical DEM results for the samples with zero, one and

three oversized particles. These figures shows the force chains

and their intensity (the thicker the force chains, the bigger are

the force chain value, their maximum values are shown on top

of the figures) for the samples with 3.5 mm of horizontal

displacement.

An analysis of Fig. 7 indicates that the larger force chains which

were compressive in nature were directed toward the large

particles and were transmitted to them by the smaller

surrounding particles. When the horizontal displacement in the

simulated test reached a 3.5 mm value, the force chains were

inclined at about 45 and 135 degrees with respect to the

horizontal axis of the cross sectional area of the large particles.

It is usually assumed that when samples of granular materials

with oversized particles are subjected to either compressive or

direct shear stress conditions, the smaller particles in the

mixture distribute the loads uniformly around the perimeter of

the bigger particles. This uniform load distribution produces

low compressive stresses on the bigger particles which allows

them to survive without breakage (Fragaszy et al., 1992). The

results shown by Fig.7 indicate that this is not the case. Under

direct shear, the smaller particles concentrate on the oversized

particles, large compressive forces that are exerted on a small

section of the perimeter of the large particles. These high

concentrated compressive forces exerted by the smaller particles

60

100

140

180

220

260

300

340

0

0.01

0.02

0.03

0.04

0.05

Area concentration, Ca

Shear strength (kPa)

Lab. results (99.6 kPa)

Sc = Sm(1+2Ca) ; 99.6kPa

Lab. results (199.3 kPa)

Sc= Sm(1+2Ca) ; 199.3 kPa