2615

Technical Committee 211 /

Comité technique 211

After the triaxial tests were completed, the specimens were

dried in a furnace and weighed, and the CaCO

3

precipitation in

each specimen was then obtained by measuring the decrease in

mass resulting from CaCO

3

decomposition by hydrochloric acid.

3 TEST RESULTS

3.1

Relationship between the amount of nutrient mixture

injected and the CaCO

3

precipitation

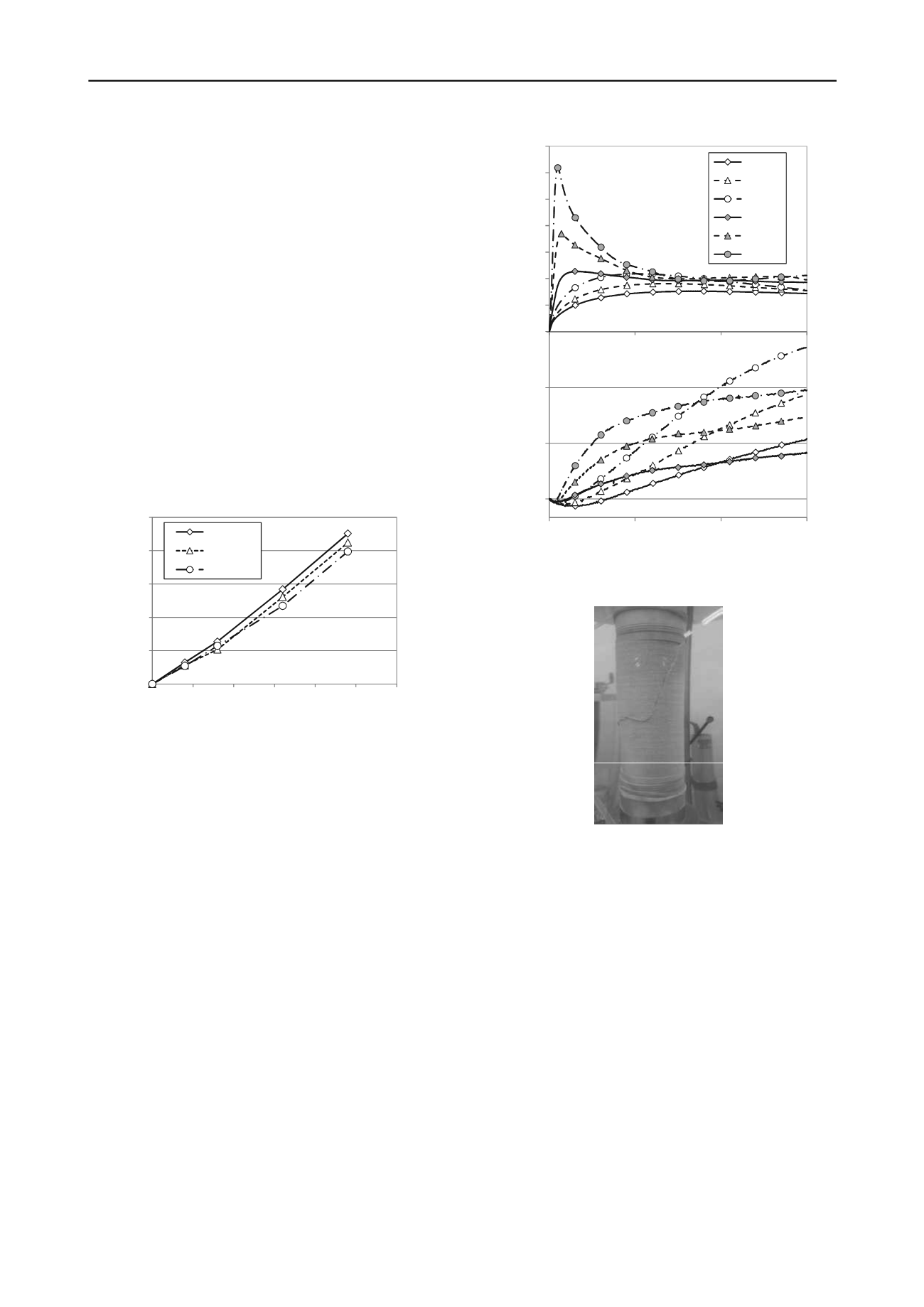

Figure 2 shows the relationship between the amount of nutrient

mixture injected and the CaCO

3

precipitation. The quantity of

CaCO

3

precipitation is given per unit volume of the test

specimen.

The tendency for CaCO

3

precipitation to increase as the

injections of the nutrient mixture increased can be confirmed for

each relative density. When the total injection of the nutrient

mixture is less than 800 ml, the differences among specimens

with different densities is unclear. When more than 800 ml of

the nutrient mixture is injected, the differences among the

specimens with different densities are observed. It is confirmed

that lower the relative density, the more CaCO

3

precipitates.

This is because the low relative density increases the amount of

microbes and nutrients absorbed by the test specimen.

0

50

100

150

200

250

0

500 1000 1500 2000 2500 3000

CaCO

3

precipitation (kg/m

3

)

Total amounts of nutrient injection (ml)

Dr = 30 %

Dr = 60 %

Dr = 85 %

Figure 2. Total amounts of nutrient mixture injected and CaCO

3

precipitation

3.2

Relationships among axial strain, principal stress

difference, and volumetric strain

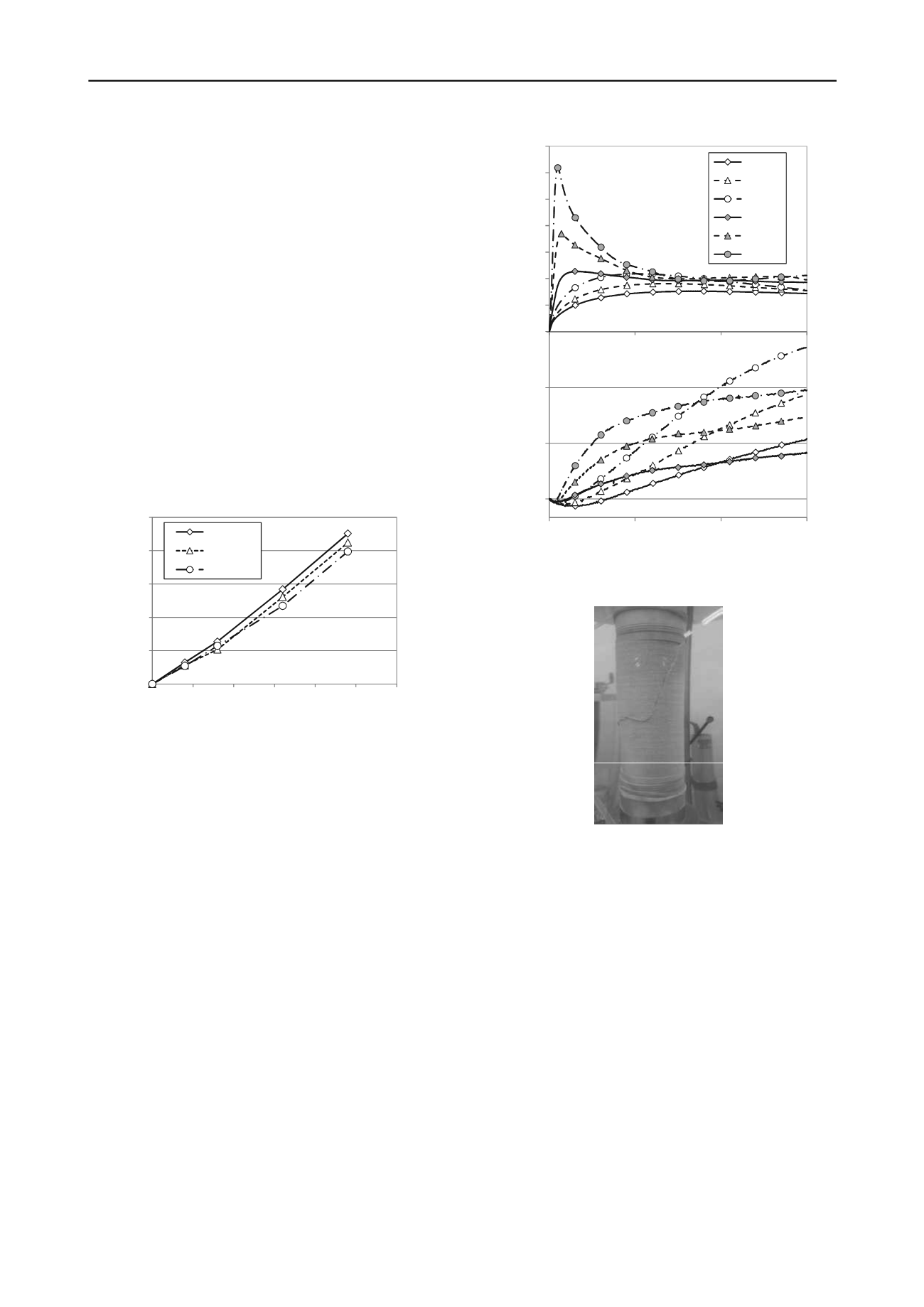

Figure 3 shows the principal stress difference

–

axial strain

curves and volumetric strain

–

axial strain curves. Toyoura sands

of each relative density saturated only with distilled water

(unsolidified) and those injected with 800 ml of the nutrient

mixture and CaCO

3

precipitation of 51.8

–

63.7 kg/m

3

are shown

in Fig. 3. Photo 2 shows the solidified test specimen after shear.

It can be confirmed that the solidification caused by the

CaCO

3

precipitation leads to an increase in the maximum

principal stress. In specimens with about the same CaCO

3

precipitation, the higher relative density of the soil, the increase

in the maximum principal stress difference is the greater. Strain

softening behavior is observed when the principal stress

difference reaches the maximum in the solidified test specimen.

A residual state occurs when axial stress reaches 5% or more;

then, the principal stress difference is constant at every relative

density, and its value shows no difference at each relative

density. It is thought that the principal stress difference becomes

equality in the residual domain because the test specimen is

sheared along the sliding surface. Photo 2 also shows a shearing

plane along the sliding surface. The increase in the volumetric

strain on the expansion side is confirmed clearly in the

solidified test specimens when the axial strain is small at each

relative density in comparison with the unsolidified test

specimens, and the ratio of increase becomes small around an

axial strain over 5%.

-9

-6

-3

0

0

5

10

15

Volumetric strain (%)

Axial strain (%)

0

200

400

600

800

1000

1200

1400

0

5

10

15

Principal stress difference (kN/m

2

)

Dr30-N

Dr60-N

Dr85-N

Dr30-P2

Dr60-P2

Dr85-P2

Figure 3.

Relationships among axial strain, principal stress difference,

and volumetric strain (

c

’

= 100 kPa)

Photo 2. Condition of the test specimen after shear

3.3

Relationship between CaCO

3

precipitation and maximum

principal stress difference

Figure 4 shows the relationship between CaCO

3

precipitation

and the maximum principal stress difference. There is no

change in the maximum principal stress difference when CaCO

3

precipitation is less than 30 kg/m

3

at each relative density. At

precipitation levels greater than 30 kg/m

3

, the maximum

principal stress difference increases monotonically depending

on CaCO

3

precipitation. The increase in strength is remarkable

in test specimens have higher relative density but little CaCO

3

precipitation. In the case of Dr = 85%, in comparison with Dr =

30% and Dr = 60%, the maximum principal stress difference

increases even as CaCO

3

precipitation stays at the same level.

3.4

Relationship between CaCO

3

precipitation and secant

modulus

Figure 5 shows the relationship between CaCO

3

precipitation

and the secant modulus. The secant modulus was calculated

from the principal stress difference at the axial strain of 0.4%.

At each relative density, there is little change when CaCO

3

precipitation is less than 30 kg/m

3

; however, when CaCO

3

precipitation is more than 30 kg/m

3

, the secant modulus

increases linearly according to the increase in CaCO

3

precipitation.