2626

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

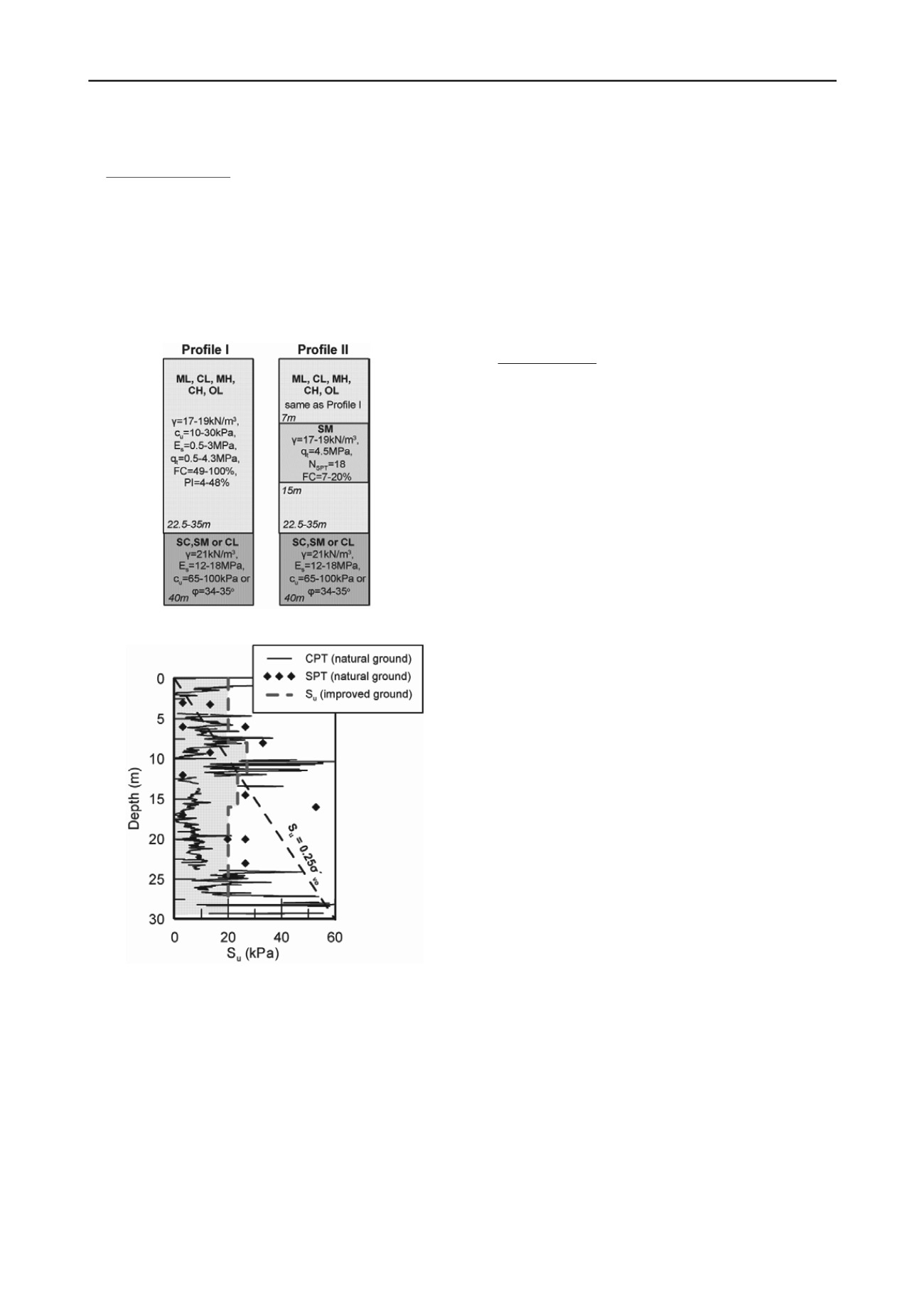

geotechnical conditions at these areas can be simplified in two

main profiles.

Soil profile I (Fig. 1) is encountered in the majority of the

bridge sites. Its main characteristic is the surficial layer of fine-

grained medium plasticity soil. According to the geotechnical

exploration results, this soil layer consists mainly of low to

medium plasticity silts (ML) and clays (CL), with thin layers of

high plasticity silts (MH), fat clays (CH) and organic clays

(OL). The thickness of this layer varies between about 22.5 to

35m. Below this layer, to the depth of 40m, either a medium to

dense non-cohesive soil unit (SC, SM) or a dense cohesive soil

unit (CL) are present. Rock or any other rock-like geological

formation was not encountered at any of the locations explored.

Figure 1: Representative geotechnical profiles

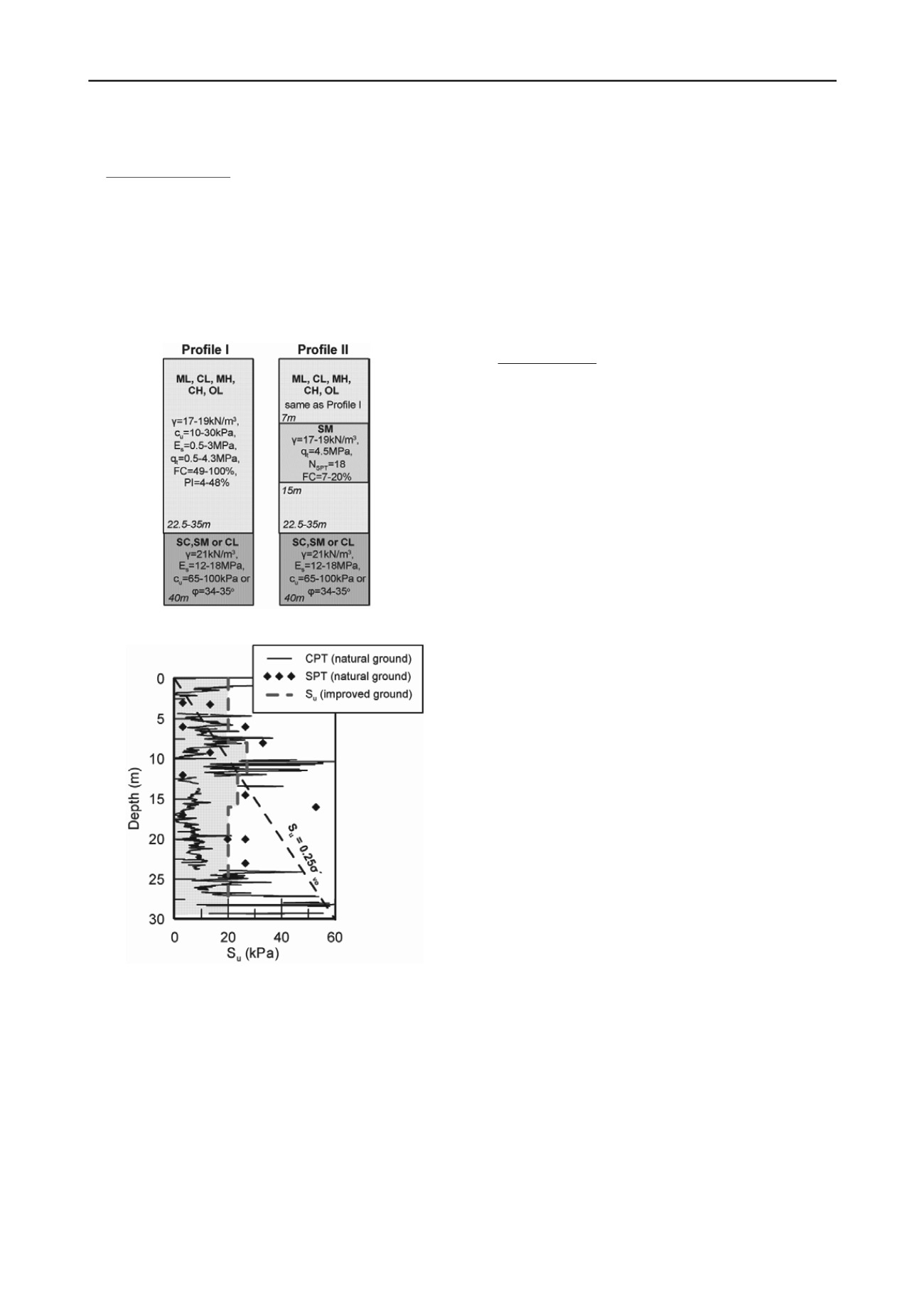

Figure 2: Distribution of undrained shear strength with depth for profile

I conditions, before and after the improvement

Figure 2 presents an estimation of the undrained shear

strength of the surficial fine-grained soil unit of Profile I, based

on the results of typical CPT & SPT recordings. An estimation

of undrained shear strength for normally consolidated clays is

also presented, based on Jamiolkowski et al. (1985) (see Eq.1):

S

u

= 0.25 σ΄

vo

(1)

where σ΄

vo

is the geostatic effective vertical stress. Comparing

these two estimations, it is concluded that the surficial fine-

grained layer is normally or even at some depths under-

consolidated, with low values of undrained shear strength. Thus,

the bearing capacity of this formation is considered low and

significant settlements are expected during loading, with the

necessary consolidation time to exceed the acceptable time

limits (horizontal coefficient of consolidation ranging between

c

h

=7x10

-7

– 9x10

-6

m

2

/sec based on CPTu dissipation tests). The

lateral resistance of this layer is also considered very low,

leading to large horizontal displacements and structural forces,

especially during seismic loading.

With regard to the seismic response, profile I belongs to

group type S1 according to EC8. The average shear wave

velocity V

s,30

generally ranges between 85 and 140m/sec, as

computed from the CPT recordings:

G

max,o

= (q

t

– σ

v

)x0.0188x10

0.55Ic+1.68

(2)

where I

c

is a soil behavior type index (Robertson, 2009). Thus,

special study is required for the definition of the seismic action,

which will take into account the non-linear response of the soil

layers and the dependence of soil moduli and internal damping

on cyclic strain amplitude.

Profile II (Fig. 1) represents the soil conditions prevailing at

one bridge site. The soil conditions resemble those of Profile I,

with the exception of an 8m thick layer of loose silty sand that

interrupts the surficial fine-grained formation. This non-

cohesive formation (SM according to USCS) is relatively close

to ground surface (at the depth of 7m), while it is classified as

non-plastic, with fines content between 7 and 20% and

potentially liquefiable under seismic conditions.

A preliminary liquefaction analysis with NCEER

methodology (Youd et al. 2001) for CPT recordings revealed

that this non-cohesive formation is liquefiable. As shown in Fig.

4, the factor of safety against liquefaction is well below unity

for the silty sand layer, revealing its high liquefaction potential.

Hence, although this soil layer presents higher stiffness

(V

s,30

=140m/s) and bearing capacity for static loading, as

compared to the clay layer, its liquefaction potential deteriorates

its mechanical properties. Thus, during earthquake loading, loss

of bearing capacity, lateral stiffness degradation and settlements

are expected to occur, increasing this way superstructure

displacements and structural forces. Furthermore, Profile II is

now characterized as Group type S2 according to EC8 and

special study is needed to define the seismic action and the

exact liquefaction potential.

4 DESIGN CONCEPT

As a result of the existing poor soil conditions, the foundation

of the foreseen bridge piers on surface foundations was

excluded and was replaced by a group of piles with a rigid pile

cap. However, due to the high seismicity of the area, the very

low P-y reaction of the soft silty clays and the eventual

liquefaction of the silty sand layer led to extreme internal forces

of the piles and increased dis-proportionally the cost of the

project. Hence, the necessity of an acceptable solution in terms

of both dimensions and cost, led to the decision to improve the

top part of the natural soil.

Among a number of possible methods of soil improvement

that were examined, it was decided to proceed with the

application of gravel piles followed by preloading. Plastic

drains are also prescribed to act as secondary drainage system

for greater soil depths.

The main aim of pre-loading was to increase the undrained

shear strength of the surficial fine-grained soil unit. The

improved undrained shear strength (when the increase of

effective stress due to surcharge exceeded 10% of its initial

value), was estimated according to Eq. 4:

S

u,f

= S

u,o

OCR

0.8

(3)

with S

u,o

reflecting the anticipated undrained shear strength for

normally consolidated clays (see Eq. 2). The increase of

effective vertical stress at each depth was computed according

to the well known Westergaard solutions, taking into account

the increase of soil stiffness at upper layers, where gravel pile

installation accompanies pre-loading. The effect of pre-loading

reduces with depth, while a percentage of the surcharge load is

used for the increase of OCR, due to the distribution of the

external load between gravel piles and original soil. Despite

that, the anticipated increase of undrained shear strength at

upper layers (i.e. at layers that are crucial for the overall safety