2634

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The natural marine clay was first mixed with the prescribed

amount of water to achieve 100% moisture content and

remoulded. Cement slurry with the water-cement ratio needed

to achieve the desired mix ratio was then added to marine clay

in a Hobart Mixer and mixed at a rotational speed of 125rpm for

around 5 minutes. The fiber was finally added to cement soil

mixing and mixed for another 10 minutes. For mixtures with

water content of 100%, the superplasticizer was used to improve

their workability. The dosage of the superplasticizer was 1.13-

2.27l/100kg soil+cement solids. The mixture was placed into a

50mm (diameter) by 100mm (height) cylindrical polyvinyl

chloride (PVC) split-mould. No compaction was applied during

placement. Specimens were then submerged in distilled water

within their split-moulds without loading for curing. The

specimens were then taken out after 7 days for unconfined

compression testing. The test procedure followed those

prescribed in ISO/TS 17892 (2004). The strain rate used for the

unconfined compression test was 1.32%/min.

3 EXPREIMENT RESULTS AND ANALYSIS

3.1

Stress strain behavior

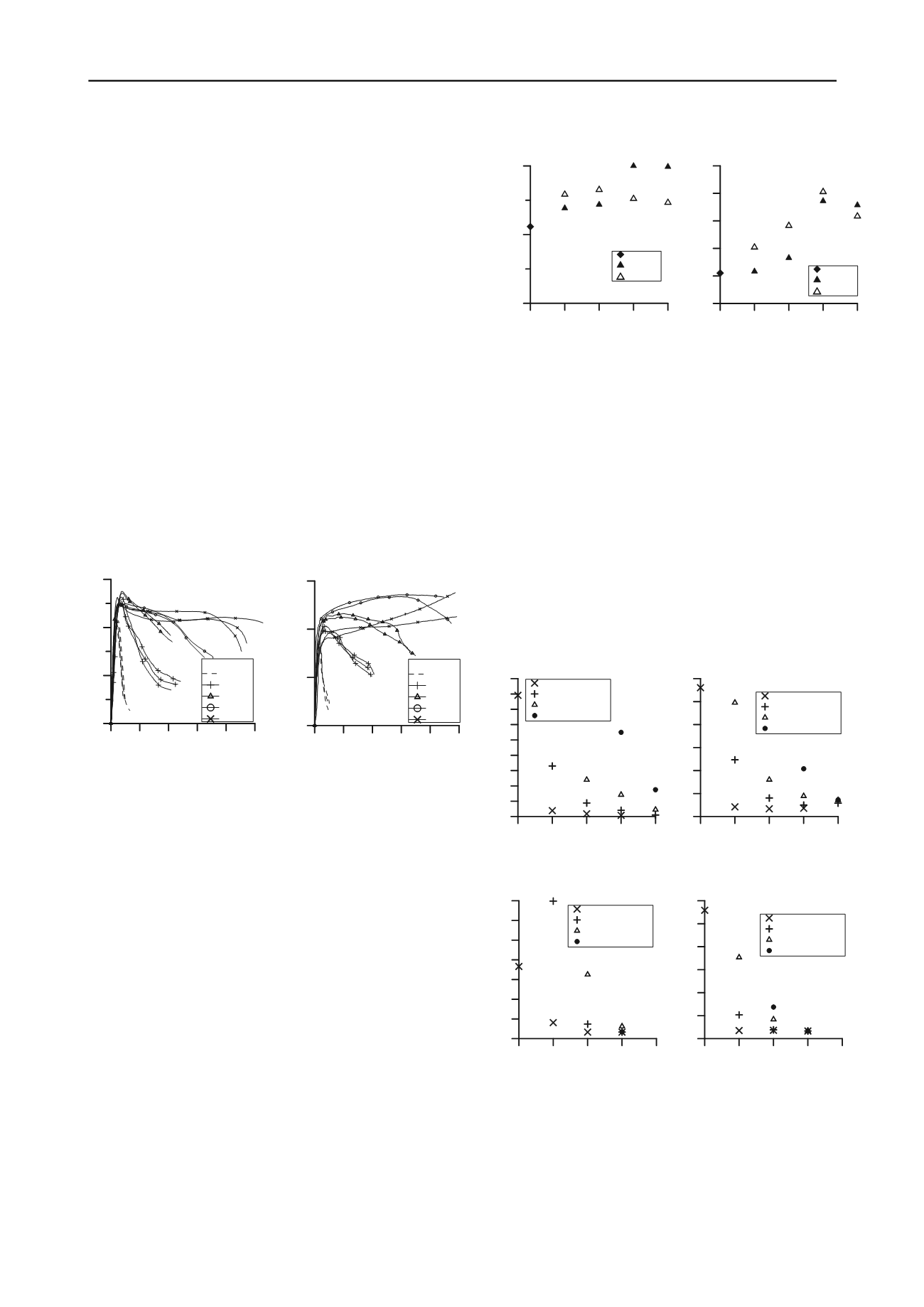

Figure 1 shows the typical stress strain behavior of FRCT soil

specimens under unconfined compression. Compared to purely

cement-treated soil, fiber reinforcement increases the strength

and ductility significantly, the ductility increasing with fiber

content.

(a) (b)

Figure 1. Stress strain behavior for FRCT soil specimens with 6mm

long fiber. (a) 50% cement content and 100% water content; (b) 50%

cement content and 167% water content.

3.2

Effect of fiber content

Figures 2-3 present the effect of fiber content on peak strength

and brittle index of FRCT soil specimens. As Figure 2a shows,

for both PP and PVA reinforced specimens with mix ratio 2:1:3

(cement content 50%, water content 100%), the peak strength

increases with fiber content until a certain fiber content (0.16-

0.24%), after which it decreases slightly. A similar trend is also

observed in Figure 2b for specimens with mix ratio 2:1:5

(cement content 50%, water content 167%).

0 0.08 0.16 0.24 0.32

fiber content (%)

500

1000

1500

peak strength

q u

(kPa)

no fiber

PVA

PP

0 0.08 0.16 0.24 0.32

fiber content (%)

200

250

300

350

400

450

peak strength

q u

(kPa)

no fiber

PVA

PP

(a) (b)

Figure 2. Effect of fiber content on strength for FRCT soil specimens.

(a) Specimens with mix ratio 2:1:3 (cement content 50%, water content

100%); (b) Specimens with mix ratio 2:1:5 (cement content 50%, water

content 167%).

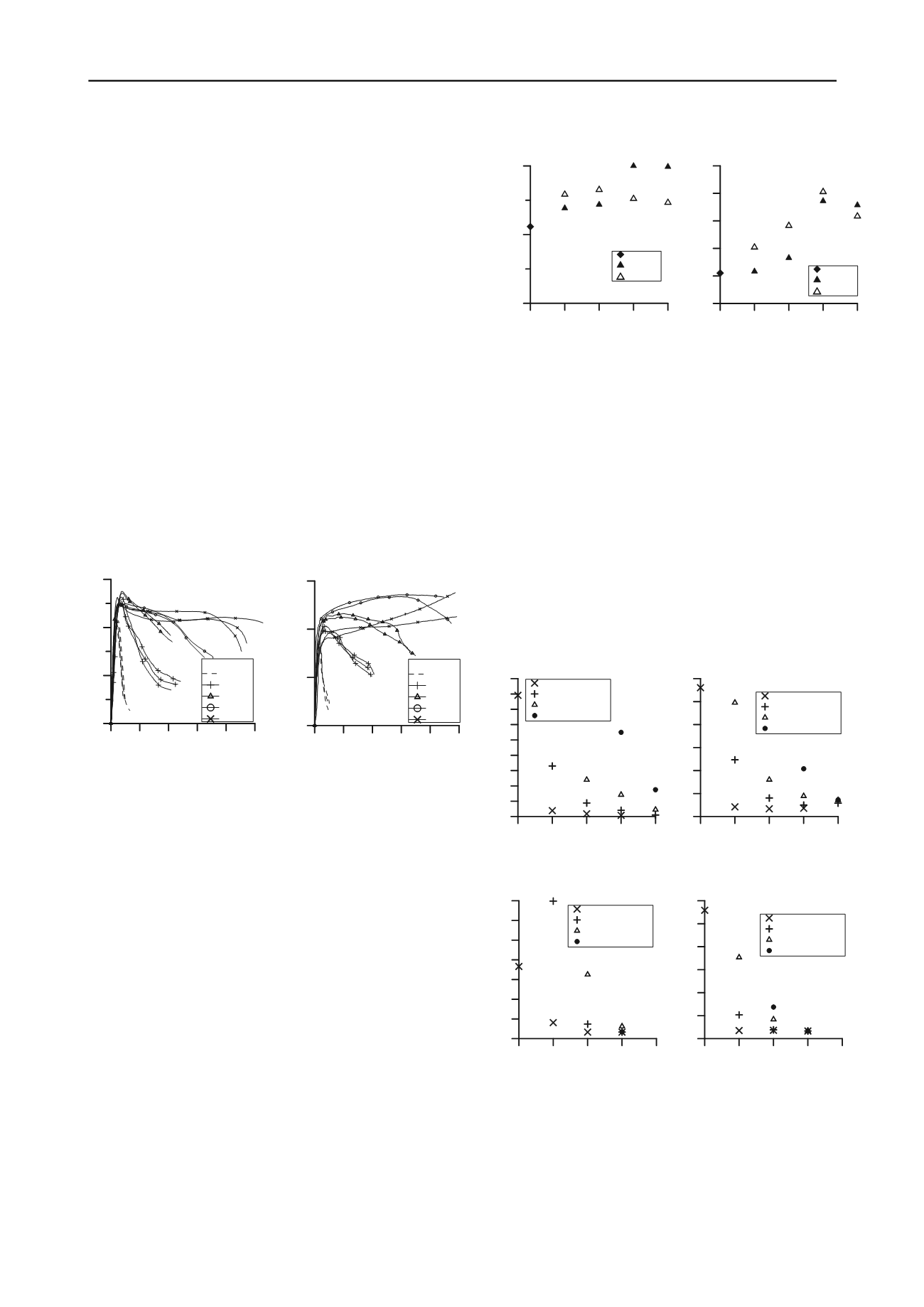

Figures 3a-3b show that the BI, evaluated at four different

axial strain levels between 2% and 20%, reduces significantly

with both PP and PVA fiber content for specimens with mix

ratio 2:1:3. A similar trend is also observed from Figures 3c-3d

for specimens with mix ratio 2:1:5. At higher fiber content, that

is, higher than 0.32% for mix ratio 2:1:3 and 0.24% for mix

ratio 2:1:5, the results were very scattered due to the poor

workability of the mix, which can be observed in Figure 1b.

Hence, with current mixing condition, the optimum fiber

content, taking into account performance and workability, is

0.32% and 0.24% for specimens with mix ratio 2:1:3 and 2:1:5

respectively. For mix ratios 2:1:4, 20:7:27 and 5:1:6, the

optimum fiber content is 0.24%.

0 0.05 0.1 0.15 0.2 0.25

axial strain (%)

0

500

1000

1500

q u

(kPa)

fiber content

no fiber

0.08%

0.16%

0.24%

0.32%

0 0.05 0.1 0.15 0.2 0.25

axial strain (%)

0

150

300

450

q u

(kPa)

fiber content

no fiber

0.08%

0.16%

0.24%

0.32%

0 0.08 0.16 0.24 0.32

PVA fiber content (%)

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

Brittleness index

2% of axial strain

5% of axial strain

10% of axial strain

20% of axial strain

0 0.08 0.16 0.24 0.32

PP fiber content (%)

0.9

1.2

1.5

1.8

2.1

2.4

2.7

Brittleness index

2% of axial strain

5% of axial strain

10% of axial strain

15% of axial strain

(a) (b)

0 0.08 0.16 0.24 0.32

PVA fiber content (%)

0.9

1.2

1.5

1.8

2.1

2.4

2.7

3

Brittleness index

2% of axial strain

4% of axial strain

8% of axial strain

15% of axial strain

0 0.08 0.16 0.24 0.32

PP fiber content (%)

0.9

1.2

1.5

1.8

2.1

2.4

2.7

Brittleness index

2% of axial strain

5% of axial strain

10% of axial strain

15% of axial strain

(c) (d)

Figure 3. Effect of fiber content on ductility for FRCT soil specimens.

(a) PVA reinforced specimens with mix ratio 2:1:3 (cement content

50%, water content 100%); (b) PP reinforced specimens with mix ratio

2:1:3 (cement content 50%, water content 100%); (c) PVA reinforced

specimens with mix ratio 2:1:5 (cement content 50%, water content

167%); (d) PP reinforced specimens with mix ratio 2:1:5 (cement

content 50%, water content 167%).