2631

Technical Committee 211 /

Comité technique 211

therefore adopted, using a method developed and extended from

EBGEO, which at the time of planning was only available in its

2004 draft stage. This extended design method was verified for

similar subsoil and loading conditions (Vollmert et al., 2006). The

anticipated further settlements at the level of the reinforcement

were estimated at less than 50 mm after termination of

construction.

Comparisons with the current EBGEO (2010), available in its

final form now that construction is complete, show that the design

and verification of the system is sufficiently robust to cater even

for the special case "Loss of Subgrade Reaction" in Load Case 3.

It must however be noted, that extreme changes in subgrade-

reaction conditions – such as its total loss – will result in load

redistribution in the sub-base layer. The long-term influence of

these on the serviceability can currently not be finally estimated

and is the subject of research. Taking serviceability aspects into

account, a conservative, realistic estimate of foundation conditions

is therefore critical in the design of such subsoil-improvement

projects.

2.3.4 Accompanying measurement

The selection of the subgrade-reaction value at the underside of

the reinforced layer is therefore a critical starting parameter for

design. Values for this are usually derived from the stiffness

modulus of the subgrade and the thickness of the weak soil layers.

The actual reaction is, however, a variable whose value depends

on, among other things, the soil improvement during the

construction phase, consolidation processes, the stiffness of the

geogrid-reinforced foundation layer and the sub-base layer.

In order to obtain further information on the subgrade reaction

and the actual behaviour of the structure, it is necessary to

investigate such structures in-situ. During the development of

Hongkongstrasse, boundary conditions for monitoring with a

measurement system were ideal, as not only the foundation soil

conditions, but also the geometric conditions and the alterations

anticipated in the medium term (development of the investor areas

and resulting encroachments into the stress distribution in the

structure) were seen as exemplary for the particular situation of

HafenCity Hamburg.

The objective of the measurement programme is therefore the

investigation and measurement of

-

the state of stress in the geogrid

-

the development of soil arching, taking construction and

operational conditions into account

-

the proportions of the load allocated to the supports and

the weak layer

-

the influence of variations in water-table level in the

foundation soil, and

-

the deformation situation at foundation level.

3. CONSTRUCTION AND MEASUREMENTS RESULTS

3.1 Sand pre-loading layer and vertical drains

After the necessary clearing away of foundations, the removal of

old services and the search for unexploded ordinance, in the

southern part of Hongkongstrasse, vertical drains were hydrau-

lically driven into the foundation soil. Plastic strip drains with a

width b of around 100 mm were used.

In installing the strip drains it was required to ensure that a

depth of soft soil of around d = 1.0 m remained under the drains as

a natural barrier to the lower groundwater aquifer (lower sands).

After this, the sand layer (including any pre-load) was placed.

Sand with a silt content ≤ 5 % by weight, a uniformity coefficient

U of approx. 2 and a rating of Z0 in accordance with the LAGA

guidelines was to be used. The sands were compacted in layers to

at least medium compaction density.

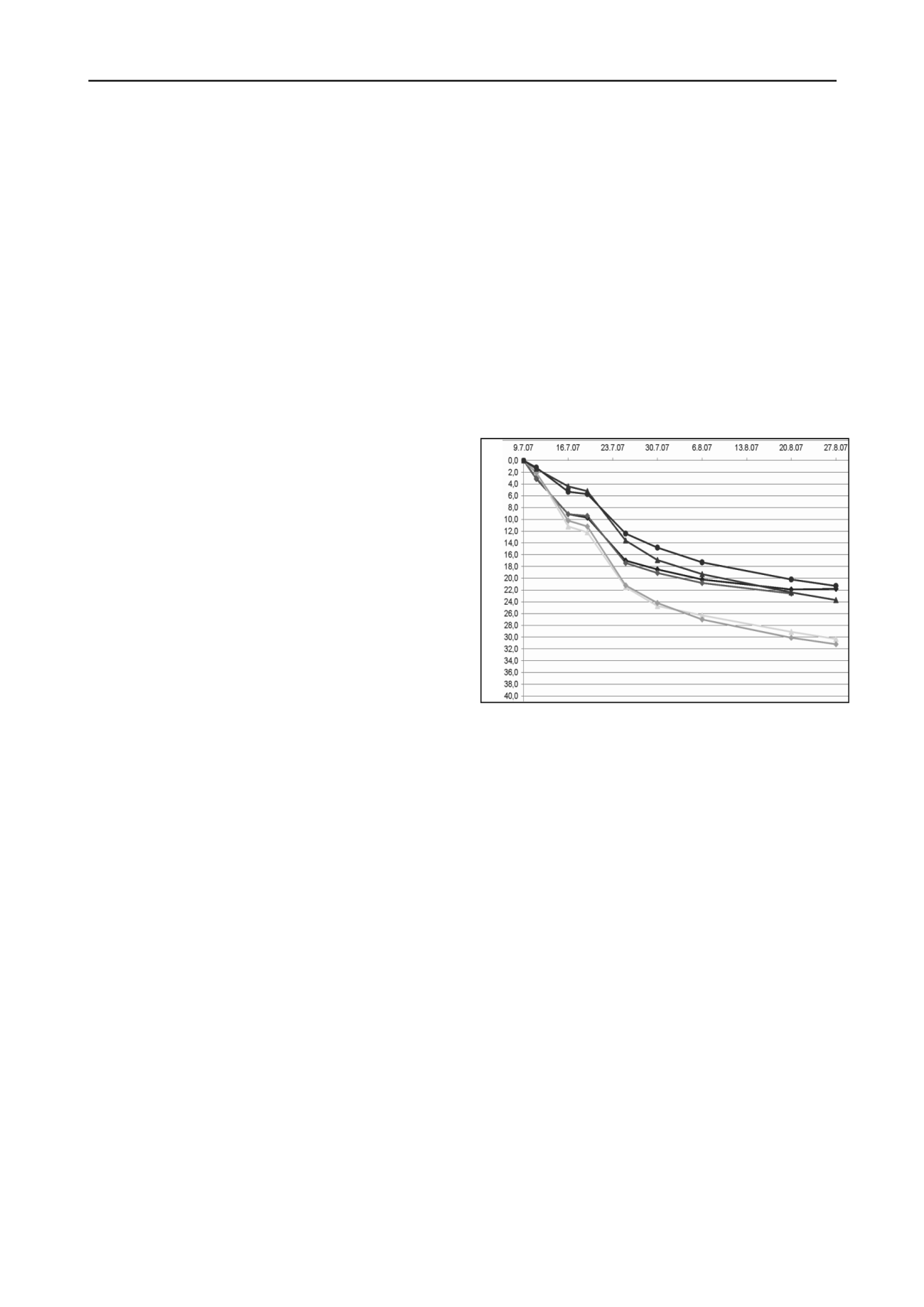

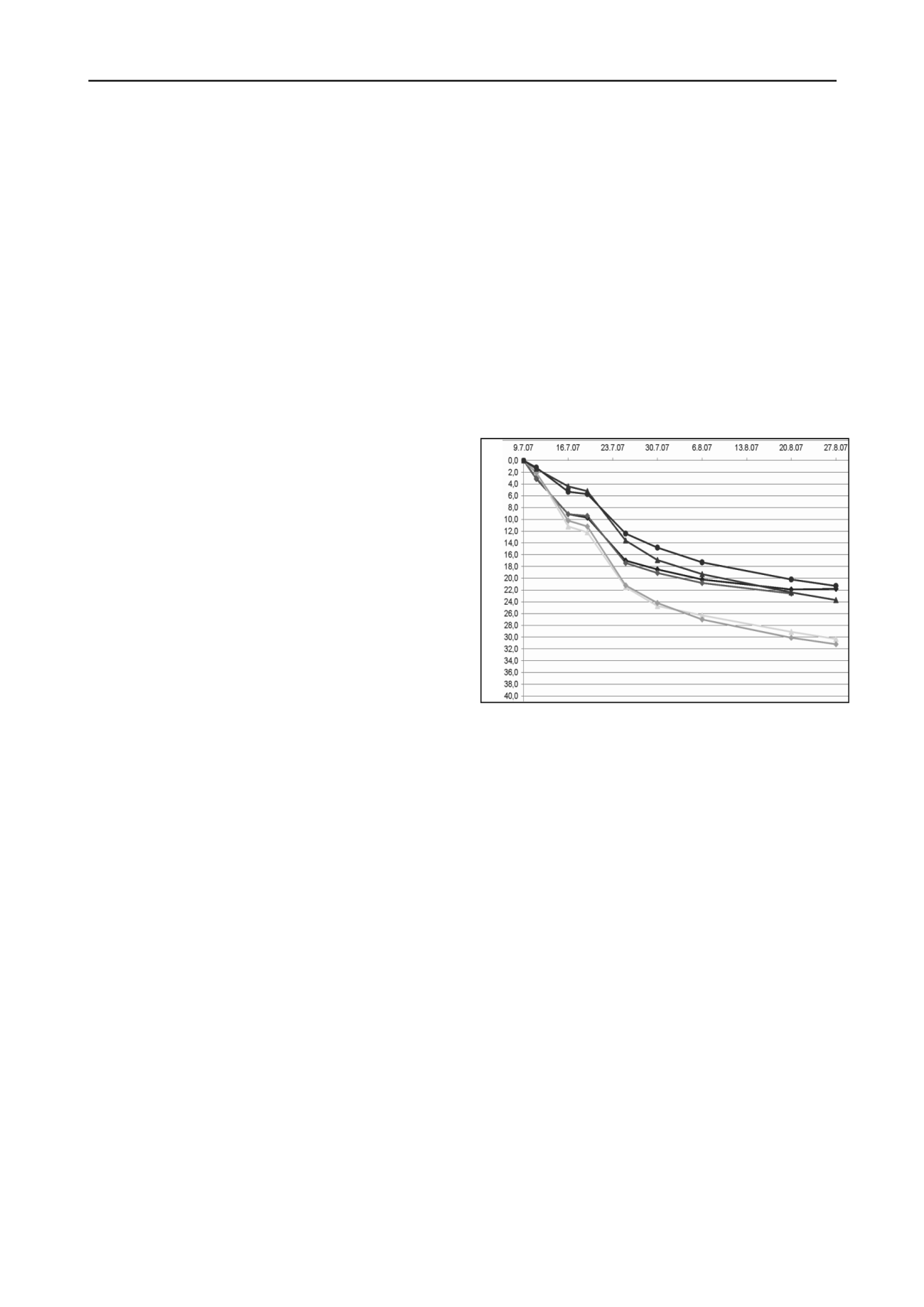

Below the level at which the sand was laid, settlement-

measuring rods, each adjustable in length and with a base plate

(1 m x 1 m) were installed, and these were continuously monitored

while the pre-load was in place. A plot of settlement against time

is shown in Figure 4.

3.2 Use of lightweight aggregate (expanded clay)

Lightweight aggregate in the form of expanded clay was used in

the northern area of Hongkongstrasse.

Various active services crossed the construction area and it had

to be ensured that these were not damaged during the excavation

of trenches, around 3.5 m deep. In the area of the services, the

expanded clay was installed in so-called big bags as a foundation

for the services. In the remaining areas, the expanded clay was

placed, spread, and compacted in layers to the design height (base

of sand protection layer) (Figure 5).

Settlements [cm]

Figure 4: Development of settlement during loading phase

3

.3

Piled, geogrid-reinforced sand base layer

3.2.1 Construction

For the required design working load of 500 kN, partial-

displacement bored columns with a diameter of 420 mm and an

unreinforced, fresh-in-fresh tapered cast cap C25/30 with a cap

diameter of 600 mm were installed by GKT Spezialtiefbau GmbH

working for Eggers Umwelttechnik GmbH.

High-strength, high-modulus geogrids Secugrid 200/40 R6 and

Secugrid 400/40 R6 were used to reinforce the sand base-layer.

The construction of the geogrid-reinforced sand layer had to be

carried out with overlap. A length of grid from the lower layer,

which was laid across the width of the base layer, was rolled and

stored at the edge of the fill. After the lengthwise reinforcement

and the fill had been placed, the stored roll was pulled up,

wrapped round the fill, and overlapped by the length required in

the design calculations (Figure 6). For a workmanlike placing it is

therefore necessary to ensure that the roll overlaps are arranged in

a staggered pattern in order to avoid distortion and twisting of the

geogrids.

The results of the measurements have been published by

Weihrauch et al. (2010) indicating the expected performance as

well as meeting the deformation requirements as given by the

design.