2630

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

loading layer and vertical drains to pre-empt settlements is an

economical standard method.

To accelerate consolidation, vertical drains are installed in the

area to be loaded. The planned, elevated cross-section is then

constructed, and an additional 2.0 to 3.0 m thick sand pre-load is

placed.

The consolidation of the weak organic layers is monitored over

time using settlement gauges.

After the time required for settlement (usually at least three

months), during which no further construction takes place, the

sand pre-load is removed to the agreed planned height and the

structure passes out of the responsibility of the earthworks

contractor.

2.2 Use of lightweight aggregates (expanded clay)

In areas where pre-emption of settlement is impractical because of

local structures or services, lightweight aggregates are often used.

These materials significantly reduce settlements resulting from the

raising of ground levels.

For forecast residual settlements of around 50 to 70 mm, the

lightweight materials are placed to a depth of around MSL + 2 m.

The expanded-clay layer is wrapped in a nonwoven geotextile

to prevent particle displacement and leaching-in of soil.

The use of expanded clay is regulated in the "Merkblatt über

die Verwendung von Blähton als Leichtbaustoff im Untergrund

von Straßen" of the Forschungsgesellschaft für Straßen- und

Verkehrswesen (FGSV).

2.3 Construction of a piled, geogrid-reinforced sand layer

2.3.1 Construction method and system chosen

The system is characterised by vertical columns (lime-cement

treated gravel, unreinforced) and an overlying sand layer

horizontally reinforced with geogrids. Use is made of the arching

effect of the overburden sandy soil while the foundation soil acts

as a bedding layer. In contrast to concrete slabs on (reinforced

concrete-) piles, in which the individual elements are very stiff in

comparison to the surrounding soils, there is a pronounced

interaction between the columns, geogrid and the foundation soil

in the system described here.

In contrast to

the methods described under 2.1 and 2.2, the

foundation soil in this system is only subjected to low additional

stresses. The major part of the vertical stresses is transferred in a

concentrated manner by the vertical columns into the firm

foundation soil. The system settlements remain proportionally

very small both during and after the construction phase.

When correctly designed, the system possesses significant

reserves of bearing capacity, so that subsequent interventions and

changes within limits in the foundation soil have no influence on

the serviceability of the structure.

The placement grid of the supporting elements should be

designed to transfer the geogrid loads in an orthogonal manner.

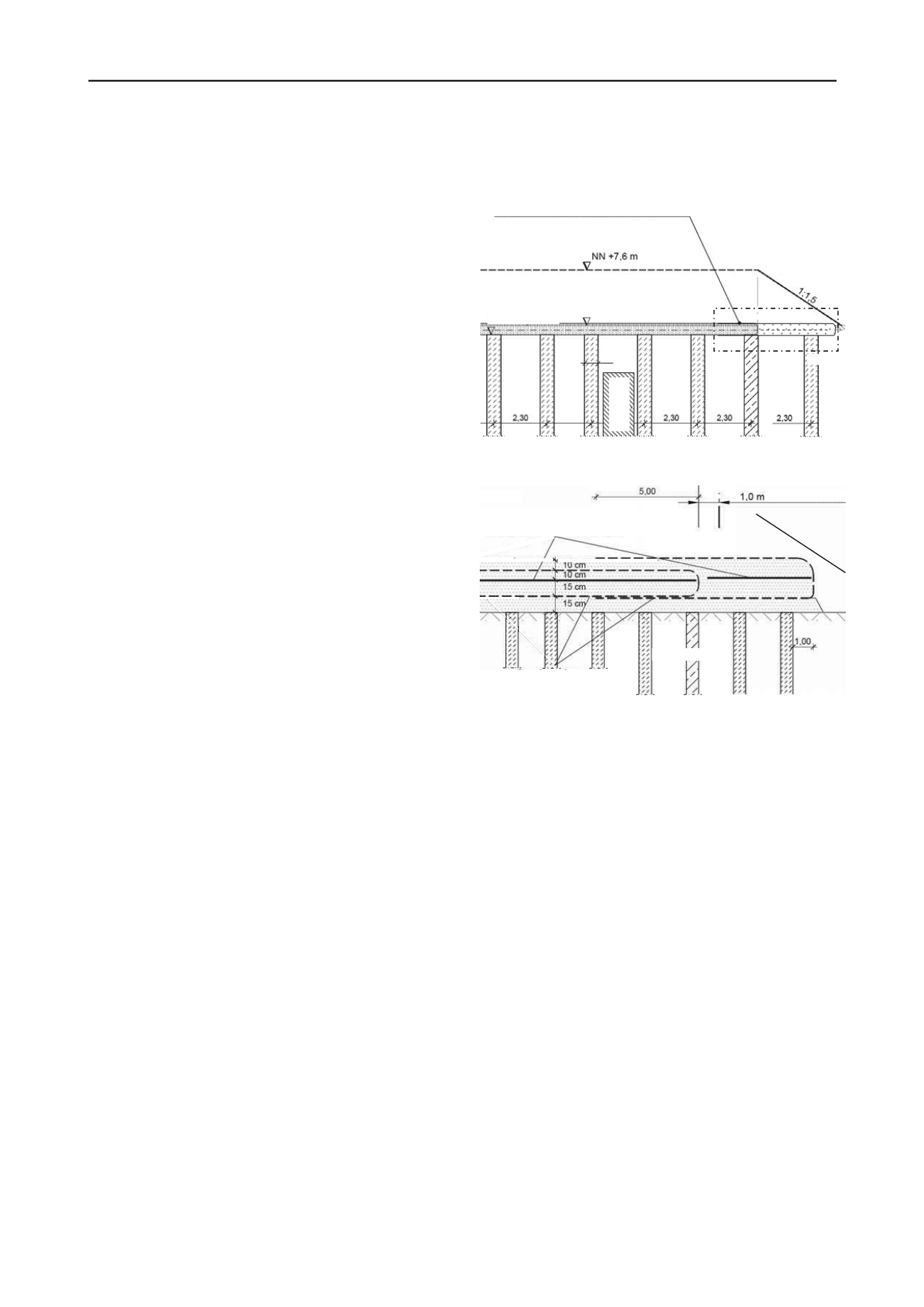

For Hongkongstrasse, this resulted in a rectangular grid with a

spacing of 2.3 m normal to the embankment axis and 2.5 m in the

axial direction; the diameter of the elements was 0.6 m (Figure 2).

Reinforced-concrete columns with continuous steel reinforcement

were used at the edge of the structure to cope with a bending

moment (e.g. should any excavation be required at a later date) as

a result of lateral pressure.

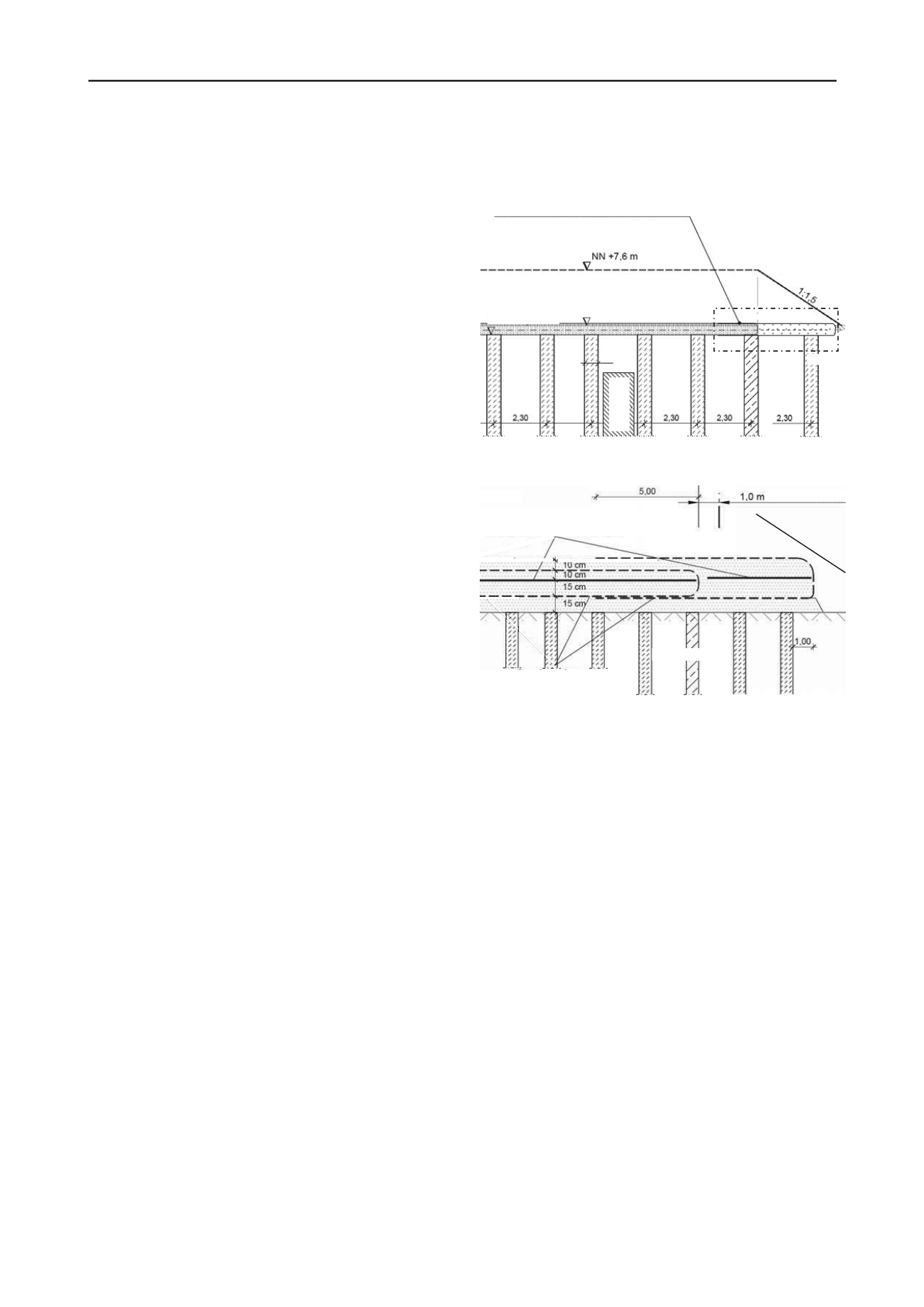

The geogrid-reinforcement is installed 150 mm above the

columns in order to guarantee adequate safety against shear during

the construction phase, and in case of large settlements. The

reinforcement is placed at right angles to the placement grid, so

that the layers are cross-laid in the longitudinal and transverse

directions of the embankment.

In the transverse direction, the constructive situation leaves

practically no room to anchor the geogrid. The design requirement

of a short-term tensile strength of 400 kN/m is therefore assigned

to two layers, which are wrapped round at the edges of the

structure, and overlapped in the upper layer.

MSL +5.2 m (prev. GL)

MSL +4.8 m

0.6

reinforced-concrete

l

filled

old sewer

Detail A

0.5 m geogrid – reinforced sand layer

Figure 2: Cross section – piled sand layer

Figure 3: Detail A – sketch of system showing reinforcement placing

(vertical scale greater than horizontal)

2.3.2 Points of constructive relevance near Hongkongstrasse

To avoid the risk of subsequent construction activity of investors

endangering or destroying sections which have already been built,

an area of 1.0 m of the traffic section must be able to be removed.

Fill which intrudes into investor areas must also be removable.

In order to prevent any damage to the embankment-support

system, the geogrid-reinforced fill layer was built with sufficient

overlap (Figure 3). The outer section can thus be removed in the

course of normal earthworks.

2.3.3 Design and verifications

The design of the support system is performed for the columns

and the geogrid-reinforced fill layer in co-ordination with one

another.

The columns are designed for the total load, and the

contribution of the subsoil to load bearing and subgrade reaction

between the columns is neglected.

The geogrid-reinforced layer was designed according to a

verification concept which has already been used and proven itself

several times in HafenCity Hamburg. The limit bearing capacity

was first verified in accordance with a suggestion from Kempfert

et al. (1997). A conservative value for subgrade reaction was used.

This verification procedure does not enable any deformations to

be inferred.

However, verification of serviceability and of deformation

limitation is compulsory for all construction projects in the

HafenCity Hamburg. A complementary design procedure was

1:1.5

(for investors)

reinforcement in longitudinal direction,

Secugrid 400/40 R6

weak layers

reinforcement in cross‐direction,

Secugrid 200/40 R6