2551

Technical Committee 211 /

Comité technique 211

4 Geomaterial soil-cement colUmn

characteriZation

the cement used for the construction of soil-cement columns

was of the portland type cem i 52.5 sr. the slurry mix was of

a cement / Water type with the relation 1/1. the average

penetration rate for the construction of columns was 30 cm/min

with the rotation velocity of 50 to 55 rpm and the average

cement consumption of 350 kg/m

3

.

the unconfined compressive strength tests (Ucs) were

performed both on drilled core samples and wet grab samples

(cylinder dimensions height / diameter > 2), both of them

usually being the main mean of the quality control of wet deep

mixing methods. three core samples were taken from different

soil-cement trial test columns, 21 days after the completion of

the soil-cement columns. the samples were cored at a distance

of 110 mm to 120 mm from the centre of columns. the overall

average total core recovery was more than 97% for all soil-

cement columns. Wet grab samples were taken in the half an

hour after execution of columns and were tested at same age as

core samples. the Ucs tests were also used to determine the

stiffness modulus e

50

(secant value of Young´s modulus of

elasticity determined at 50% of Ucs).

the Ucs values of wet grab samples after 7 days varied

from 1.4 to 3.9 mpa, while Ucs values for drilled core samples

on 28 days ranged from 2.2 to 4.4 mpa and axial failure strain

values varied from 1 to 1.2 %. stiffness modulus values

determined from Ucs tests varied from 270 to 330 mpa, with

the average relationship between e

50

and Ucs resulting in

approximately 100.

some of the drilled core samples extracted from soil-cement

trial test columns is presented in figure 4. it can be observed

uniformly treated springsol

columns.

figure 4. drilled core samples of soil-cement columns.

5 nUmerical model

5.1

General data

When using finite element analysis to model deep mixed

columns installed in a periodic pattern, the problem is usually

modelled in a 2d axisymmetric model, referred as a unit cell

model. the homogenization equivalent model is usually not

used due to lack of access to column stresses.

the radius of the unit cell depends on the grid spacing:

s R

eq

(1)

where: r

eq

is the radius of the unit cell and s is the grid

spacing.

in this project different square grid patterns (grid spacing

varying from 1.50 to 2.00 m) depending on the surcharge of the

slab (ranging from 10.00 to 20.00 kn/m

2

) are taken into

account.

in this study the commercial finite element code used for 2d

modelling is plaxis (version 8.6). Both the soft soil and the soil-

cement column behaviour are modelled by the elastic-plastic

mohr-coulomb failure criterion, while the slab is characterized

by the elastic law. the load transfer layer formed by grouting

the gap within the contact gravel layer below the existing slab

of the approximate thickness of 20 cm is modelled by the mohr-

coulomb law. Geotechnical parameters of each material (ltl-

load transfer layer, cU-upper clay layer, cm-medium clay

layer, nsc-natural soil clay layer, sc-soil cement column) used

in the numerical analysis are given in table 2.

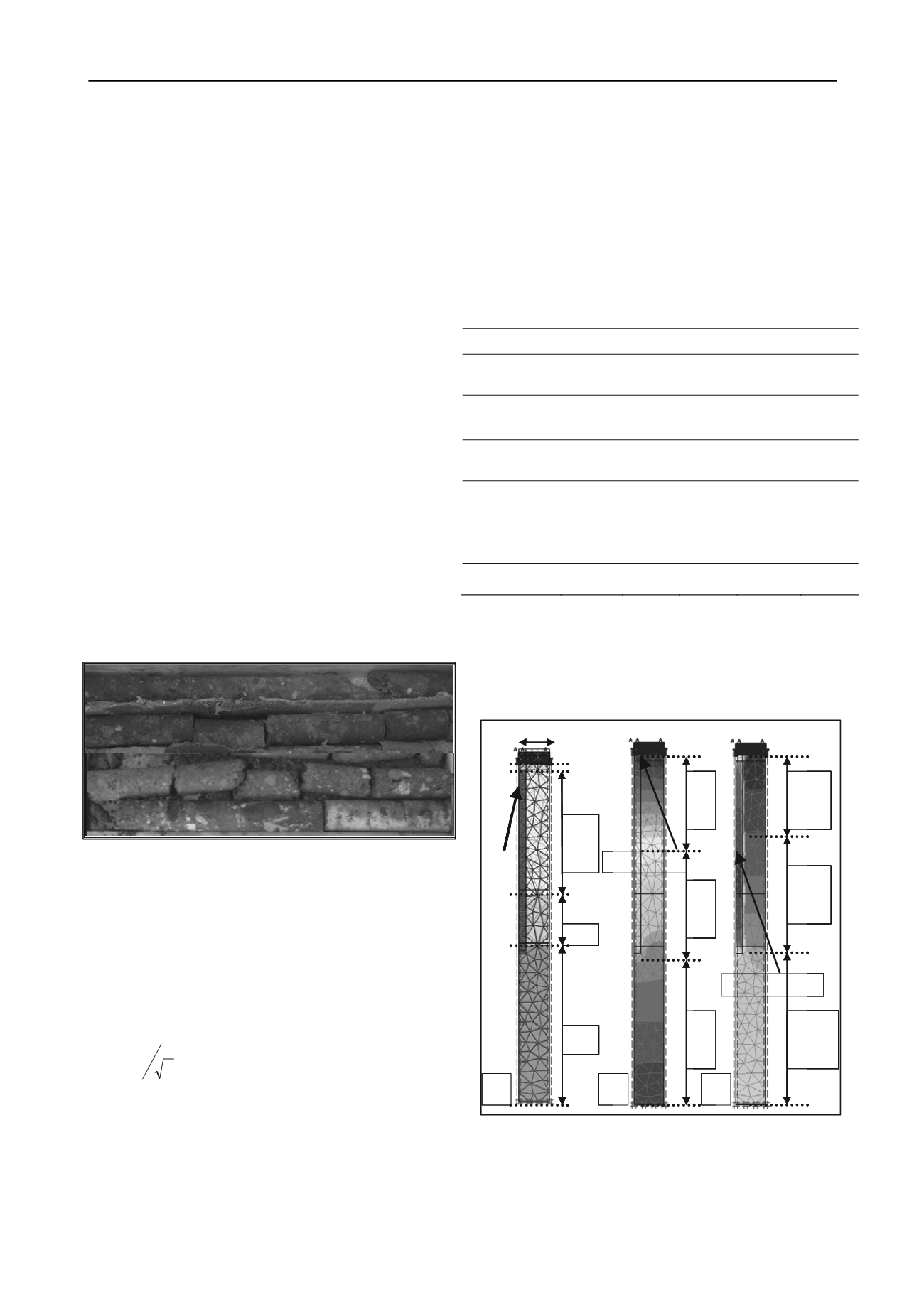

the cross section of the fe model is presented in figure 6

showing the geometry and soil layers used in analysis, as well

as the finite element mesh.

table 2. material parameters.

parameter

LTL

CU CM NSC

SC

thickness

(m)

0.2

4.0-

6.5

1.5

>4.5

density

(kn/m

2

)

22

16

17

18

20

cohesion

(kpa)

500

5

10

20

500

friction

angle (º)

40

18

20

22

35

Young

´

s

modulus (mpa)

300

2.5

5.0

50

300

poisson ratio

0.2

0.3

0.3

0.3

0.2

5.2

Results

figure 6 present the employed mesh in the fem model, and the

results regarding vertical displacements and axial stresses for

the case of the grid spacing of 1.50 m corresponding to the

surcharge of 20 kn/m

2

.

figure 6. numerical modeling results for reinforced soil. (a) Geometry

of the unit cell – mesh and model dimensions. (b) Vertical

displacements. (c) axial stresses.

max 7.85 mm

5-8

mm

2-5

mm

0-2

mm

max 385.6 kN/m

2

0-50

kN/m

2

50-150

kN/m

2

150-200

kN/m

2

R

eq

1.5m

4.0m

-

6.5m

SC

CM

CU

LTL

4.5m

NSC

a

b

c

the homogenized settlements as well as negligible

differential settlements due to high rigidity of the load transfer

layer, formed by grouting the layer of gravel below the slab, and

soil-cement columns can be observed in figure 6-b.