2558

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

is being examined at a depth of up to 10 m, where solid clay

lies.

figure 2. Geological profile

table 1. average values of the soil layers characteristics.

no.

soil type

e

-

γ

kn/m

3

c'

kpa

φ'

deg

E

mpa

1 top soil

1,35

1,45

11,0

8,0

3,5

2 Black clay

1,30

1,62

15,0

5,0

3,5

3 Brown clay

0,95

1,86

32,5

7,0

8,5

4 silty clay

1,41 1,70 11,0

5,0

6,0

5 sandy clay

0,82

1,89

32,5

18,5

15,0

2.2

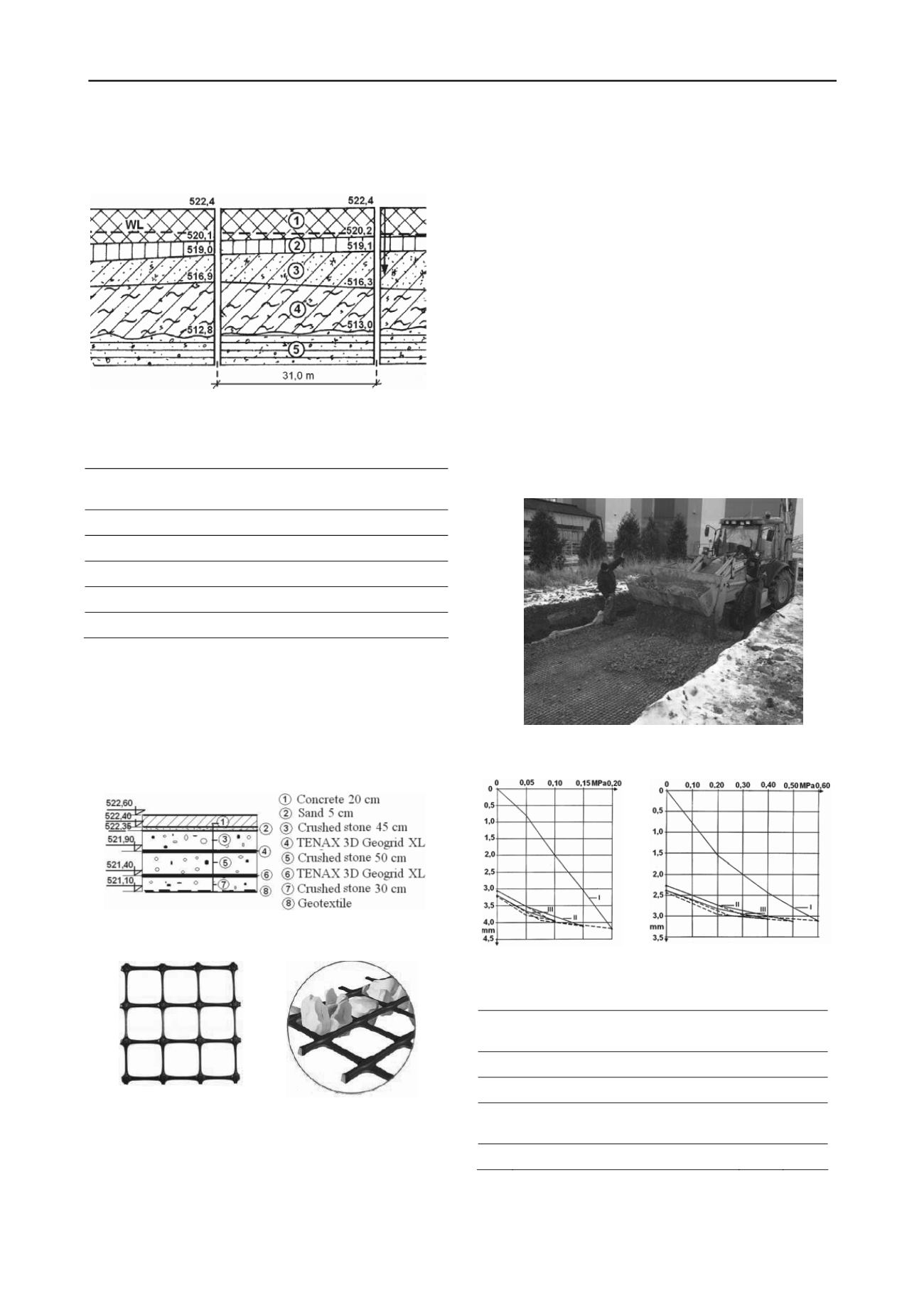

Structure of the reinforced crushed stone pad

investigations about the stress-strain behavior of the improved

soil ground with various thickness values of the crushed stone

pad, various numbers and various stiffness values of the

geosynthetic layers have been carried out in advance by fem

models. the optimal structure of reinforced pad with regard to

mechanical behavior of improved soil is obtained (fig. 3).

figure 3. structure of the reinforced crushed stone pad

figure 4. tenaX 3d Geogrid Xl (

)

the pad should be built of stone particles sized 0–85 mm,

and should be 1.3 m thick. the reinforcement is composed of

two polypropylene tenaX 3d geogrid Xl layers which have

particularly large concaved shaped ribs that enhance the

interaction mechanism between grids and stone particles by

restricting the horizontal movement of particles (fig. 4).

technical characteristics of the geogrids are: bi-axial stiffness

900/600 kn/m at 0.5% strain and coefficient of friction

soil/geogrid 1.2 (

.

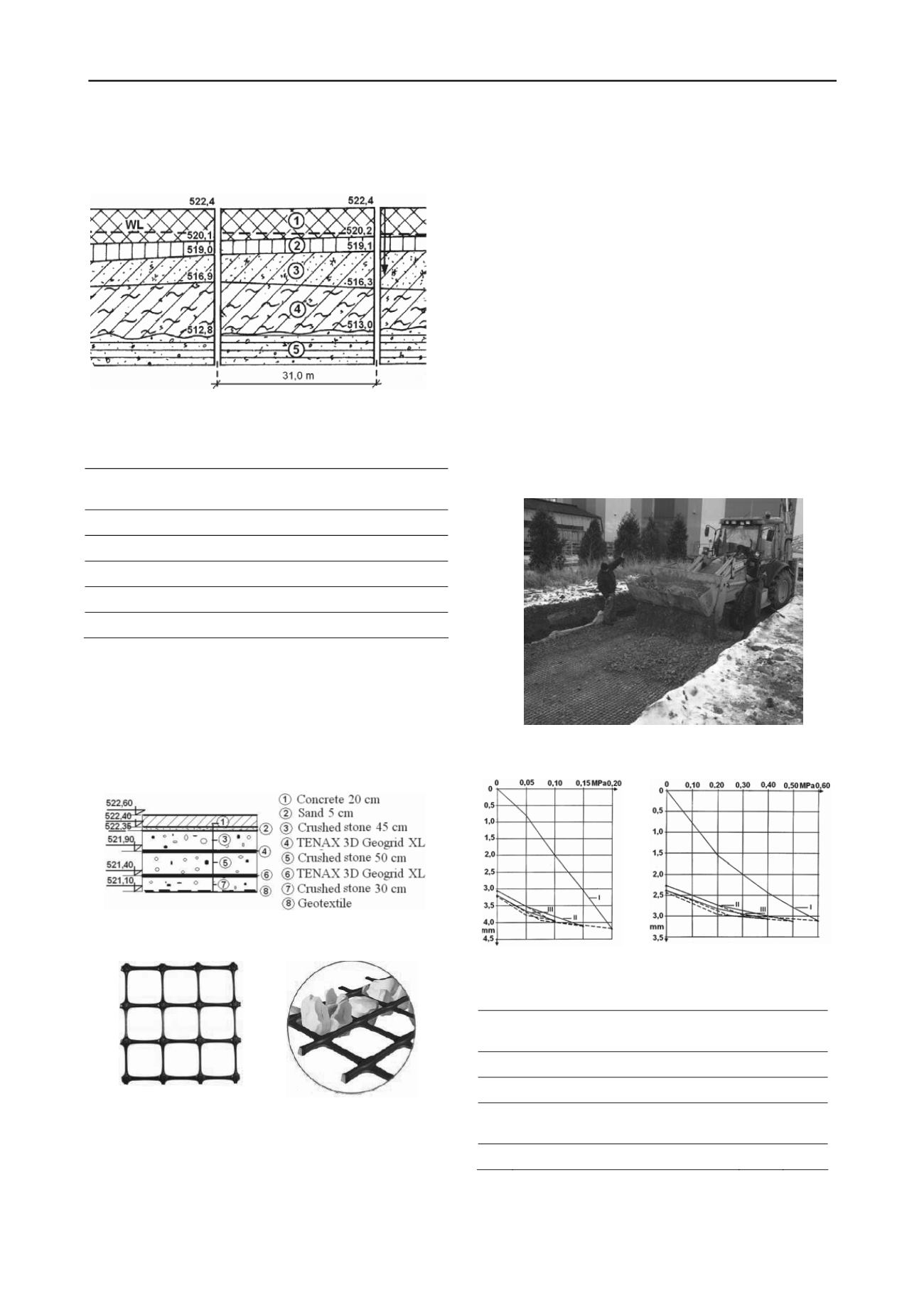

3 field testinG procedUre

to determine the e-modulus of the improved ground, a field

test program is performed. it includes the construction of the

reinforced pad of area 150 m

2

and an application of a static

loading by rigid plate of dimension 30 cm at the following four

stages of construction: (1) after compaction of the natural

ground; (2) after building the first layer of crushed stone with a

thickness of 30 cm; (3) after placing the first geogrid layer and

building the second crushed stone layer with a thickness of 50

cm; (4) at the end of the pad construction. at each stage three

loading/unloading cycles are applied by steps of 0.05 mpa and

settlement/load curves are obtained. the

E

-modulus of total

settlement and the

E

e

-modulus of their elastic part are estimated,

and the results are shown in table 2. the settlement/load curves

for the first and the last stage of pad construction are shown in

figure 6. the moduli values increase more than five times after

the soil ground improvement.

figure 5. construction of the experimental reinforced crushed stone pad

figure 6. settlement/load curves for the plate loading tests

table 2. Values of the

E

-moduli of the soil ground at field testing

no.

stage of the pad construction

E

mpa

E

e

mpa

1 compaction of the natural ground

10,0

33,0

2 the first 30-cm-thick stone layer

25,7

60,0

3 the first geogrid layer and the second 50-

cm-thick stone layer

44,3

121,0

4 the end of the pad construction

57,7

181,0