2555

Technical Committee 211 /

Comité technique 211

The pulverized clay was mixed with dry hydrated lime, and was

thoroughly rehydrated using distilled water. Two halves of the

pre-cut specimen were formed by remolding or compaction and

separately consolidated inside the top and bottom halves of the

shear box using the procedure described by Mesri and Cepeda-

Diaz (1986) and Mesri and Huvaj-Sarihan (2012). The

consolidation pressure ranged from 100 to 450 kPa, and shear

displacement rate was in the range of 3.3x10

-4

to 5x10

-4

mm/min.

Lime content as a percent of dry weight of clay ranged from

0 to 10%, and water content was in the range of 30 to 274%. In

a few direct shear tests, dry hydrated lime was sprinkled on the

exposed shear surface or on the top and bottom, of the direct

shear specimen to examine lime diffusion.

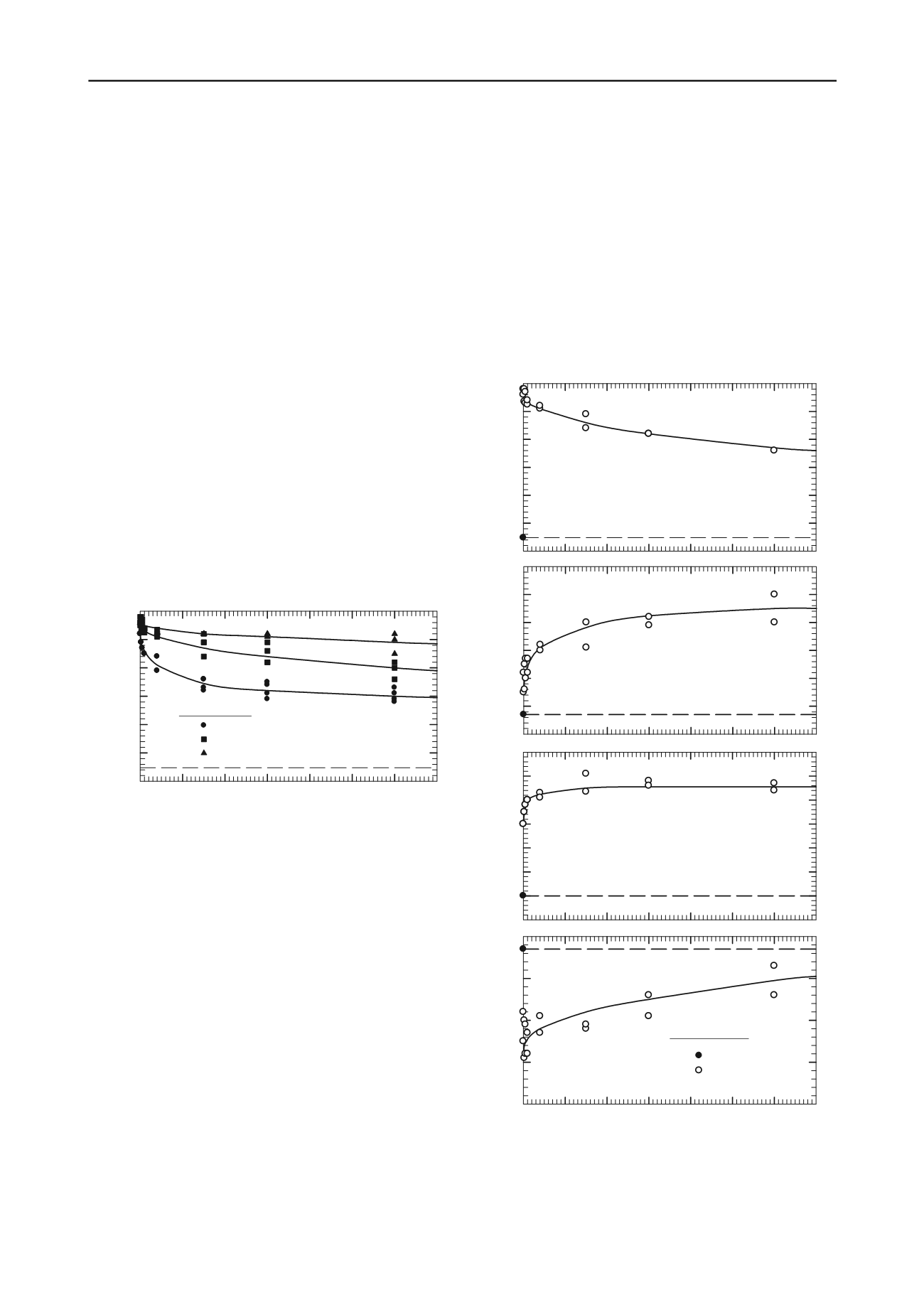

For one series of direct shear specimens with lime content

of 6.6%, liquid limit and plastic limit were determined at the end

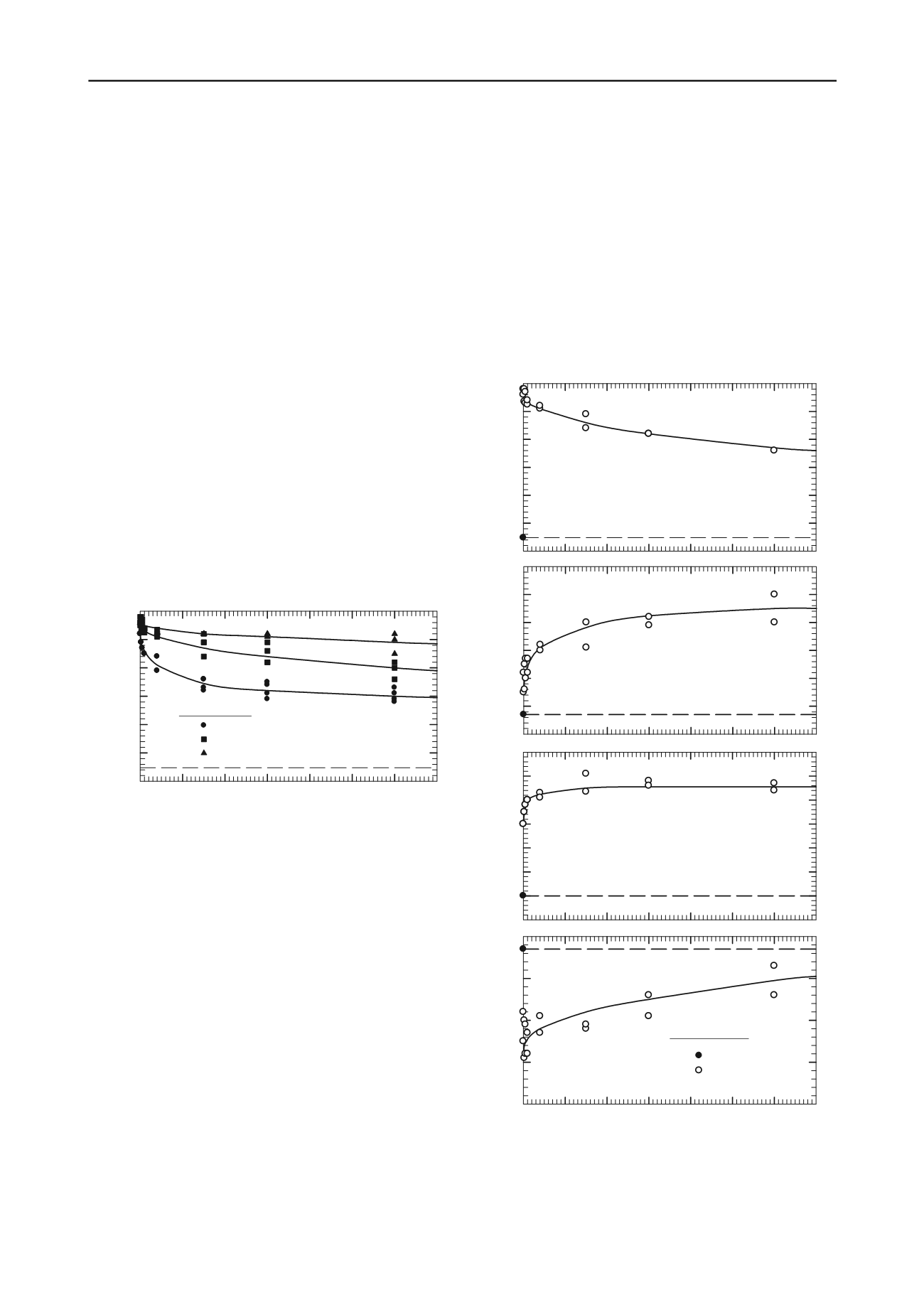

of the test. These data are shown in Fig. 1. For another series

of lime-treated Brenna clay samples with lime content of 2, 5

and 9% and water content of 80, 100, 150 and 230%, pH and

Atterberg limits were measured as a function of time. These

samples were sealed; however, they were not subjected to

confining pressure. The pH measurements are shown in Fig. 2,

and the liquid limit and plastic limit at lime content of 5% and

water contents of 80 and 100% are shown in Fig. 3.

The data on residual friction angle and fully softened

friction angle from drained direct shear tests are summarized in

Table 1. All index tests and direct shear tests reported here were

performed at laboratory temperature of 20 ± 2

C.

Curing Time, days

0

10

20

30

40

50

60

70

PH

7

8

9

10

11

12

13

2

5

9

Untreated

Lime Content, %

Figure 2. pH measurements of lime-Brenna clay

5 INTERPRETATION OF THE MEASUREMENTS

The pH measurements on lime-treated Brenna clay, such as

those in Fig. 2 as well as others, show that immediately after

introduction of lime, pH increases to a range of 12.2 to 12.7;

shortly thereafter, however, pH begins to decrease. This

observed behavior suggests that either within hours no free lime

is left to dissociate to maintain pH above 12, or dissociated

(OH)

-

is simultaneously consumed by the silica and alumina

dissolved from Brenna minerals. Nevertheless, during the 60

day observation period, pH remained above 9 suggesting

continued lime-clay chemical reactions.

The rather immediate large increase in plastic limit above

that of the untreated Brenna clay, such as observed in Figs. 1

and 3 results from flocculation and agglomeration of lime-

treated clay, especially as the water content is reduced during

the plastic limit measurements. Rapid chemical attack of

adsorbed lime on clay particles contributes to the production of

porous flocs and agglomerates that entrap water.

When the curing of lime-Brenna clay takes place

unconfined, liquid limit dramatically increases above the liquid

limit of untreated clay (Fig. 3); whereas when curing takes place

under an imposed effective stress condition, such as the

n

in

the range of 100 to 450 kPa in the direct shear tests, there is a

minor increase in liquid limit (Fig. 1). The interpretation of this

significant observed behavior appears to be that when

aluminosilicates form in unconfined condition, they hydrate

fully, thus holding significant amount of water that contributes

to the high liquid limit. On the other hand when lime-clay

reaction products form under effective confining pressure, either

the resulting aluminosilicates do not hydrate much or they

experience irreversible dehydration through consolidation, thus

resulting in little change in the liquid limit. The implication of

this behavior, which is under more detailed examination, is

significant for both laboratory study of lime-soil interaction to

improve frictional resistance as well as field application of lime

to remediate reactivated landslides.

PH

7

8

9

10

11

12

13

Untreated

Water Content, %

30

40

50

60

70

80

90

100

Untreated

Plastic Limit

80

90

100

110

120

130

140

Untreated

Liquid Limit

Curing Time, days

0

10

20

30

40

50

60

70

10

20

30

40

50

0

5

Untreated

Lime Content, %

Plasticity Index

Figure 3. Lime-Brenna clay interaction under unconfined condition

The fully softened friction angle and residual friction angle

of stiff clays and shales decrease with the increase in effective

normal stress (Mesri and Shahien 2003, Mesri and Huvaj-

Sarihan 2012 ). The secant friction angles of Brenna clay in