2546

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

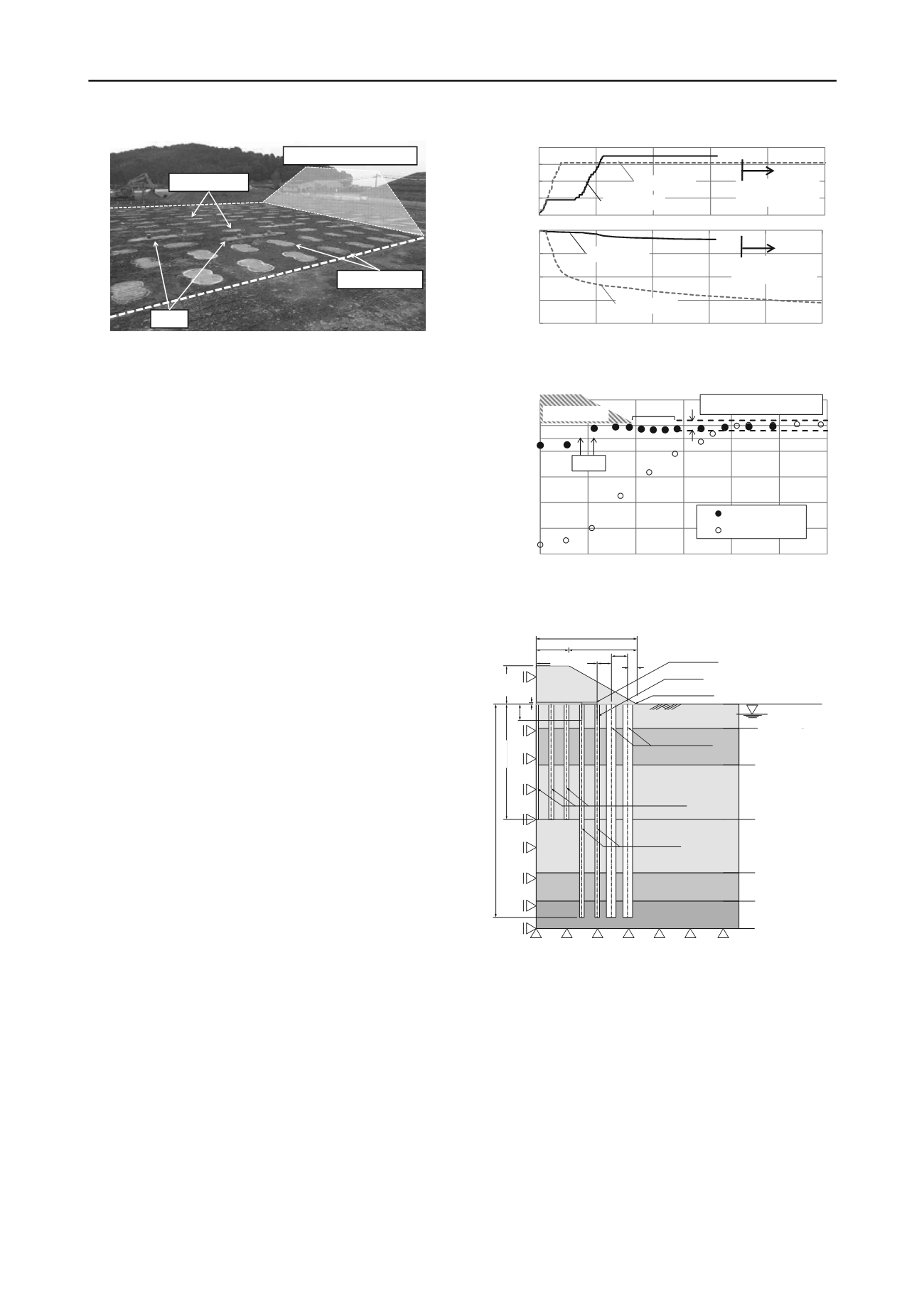

Wal l s

Out si de pi l es

I nsi de pi l es

Out l i ne of embankment

Figure 2.Ground surface after soil improvement.

bear the embankment loads as well as the lateral movement of

the soft ground. Deep mixing piles are placed inside and outside

the walls to restrict vertical and horizontal deformation caused

by the embankment.

Figure 1 shows an example of the arrangement of deep

mixing columns and walls at a site. The function and placement

of each pile and wall are explained below.

Inside piles: Columns placed in the ground directly under

the crown of the embankment. This part transfers the load from

the center part of the embankment to the deep layer.

Walls: Walls are placed in the ground under the edges of the

embankment crown. This part bears a large part of the

embankment load and prevents the soil from moving.

Outside piles: Columns placed in the ground directly under

the embankment slopes. This part transfers the load of the

embankment slopes.

This method is designed to economically satisfy the limit

value of settlement by optimizing and minimizing these parts in

the design.

3 TRIAL EMBANKMENT

3.1

Work outline

The effectiveness of this method was demonstrated in a road

construction project along the Ariake Sea in Kumamoto

Prefecture. The soft clay at the construction site was about 40 m

thick, so a large volume of settlement could be expected after

constructingan embankment 7m in height. Some parts of the

proposed road were close to residential buildings. Therefore, a

limit value for deformation was set not only for the

embankment but also for the area adjacent to the embankment,

as described below.

Embankment: Settlement sincethe start of service is equal to

or lower than 300 mm.

Adjacent area: Lateral and horizontal displacement since the

start of construction is equal to or lower than 20 mm.

During the design stage, many of the arrangements were

compared using two- and three-dimensional effective stress

analysis. After considering all of the above, the arrangement

shown in Fig. 1 was determinedto be optimal. Each column had

a design strength of 1.0MN/m

2

, and the arrangement hadan

improvement ratio of 18.5%.

Before the embankment was constructed, settlement plates

and pressure gauges were installedfor the purpose of taking

measurements. The ground surface after soil improvement is

shown in Fig. 2.

3.2

Result of construction

Figure 3 shows the settlement history of the ground surface at

the center of the embankment. The same figure also shows a

similar settlement history, observed at a trial embankment

nearby with no subsoil treatment. In the improvement case,

200mm of settlement occurred one year after embankment

construction. Subsequently, settlement converged in both cases.

0

2

4

6

8

Improvement

Starting date of

service

No treatment

Height of

embankment (m)

0

500

1000

1500

2000

0

200

400

600

800

1000

Starting date of

service

No treatment

Improvement

Elapsed days (day)

Settlement of

embankment (mm)

Figure 3.History of ground surface settlement in at the center of the

embankment.

‐100

0

100

200

300

400

500

0

10

20

30

40

50

6

Distance from center line of embankment (m)

0

Improvement

No treatment

Walls

Limit value

:±

20mm

Embankment

10m

Settlement after construction

of embankment (mm)

Figure 4.Distribution of ground surface settlement after construction of

the embankment.

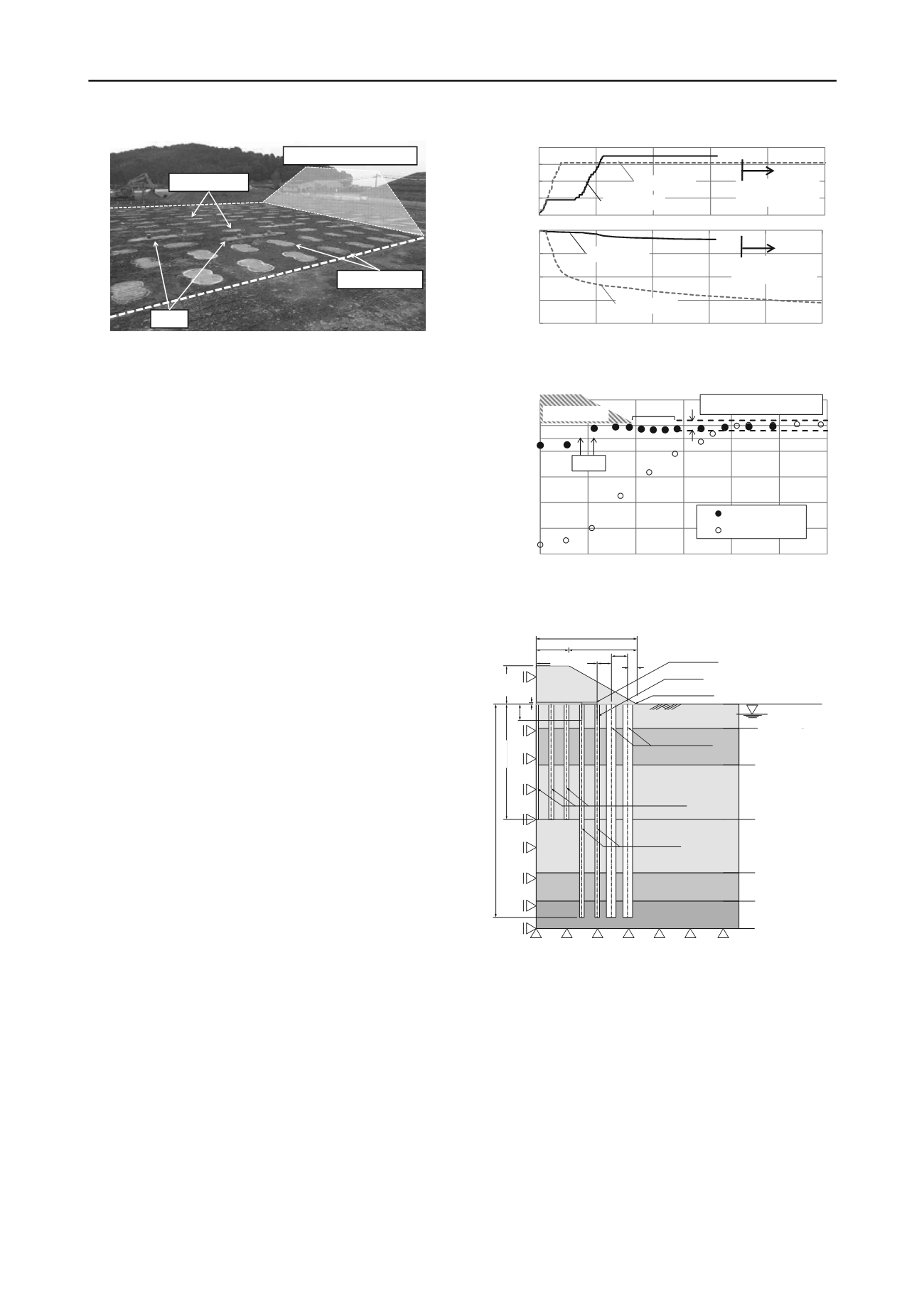

4@2810 2600 3000

12600

18600

1760

1:1.8

7000

21200

GL ‐1.90m

6000

Geotextile

Steel wire

H steel

3000

300

Inside piles

39200

Walls

Outside piles

As2

Ac2‐2

Ac1‐2

Ac2‐3

Dvc

Dvs

GL ‐4.50m

GL ‐11.20m

GL ‐21.20m

GL ‐31.00m

GL ‐36.20m

GL ‐41.60m

Figure 5.Section view of the numerical model.

Figure 4 shows the settlement history fora one-year period

after the construction road was removed.In the improvement

case, large the walls prevented deformation under the

embankment, keeping the settlement around the embankment

below the limit value. The vertical strain measured in the walls

is shown in Fig. 7; this, too, was kept below the fracture strain

value.

3.3

Back-analysis

To investigate the applicability of two-dimensional effective

stress analysisunder actual construction conditions, the

geological profile and mechanical properties of the deep mixing

columns were analyzed using Plaxis 2D Ver.9.02.

The numerical model is shown in Fig. 5. Due to the

symmetry of the embankment, only half of the geometry was

considered for the model. The distance from the embankment

Table 1.Material properties used for numerical model