2543

Technical Committee 211 /

Comité technique 211

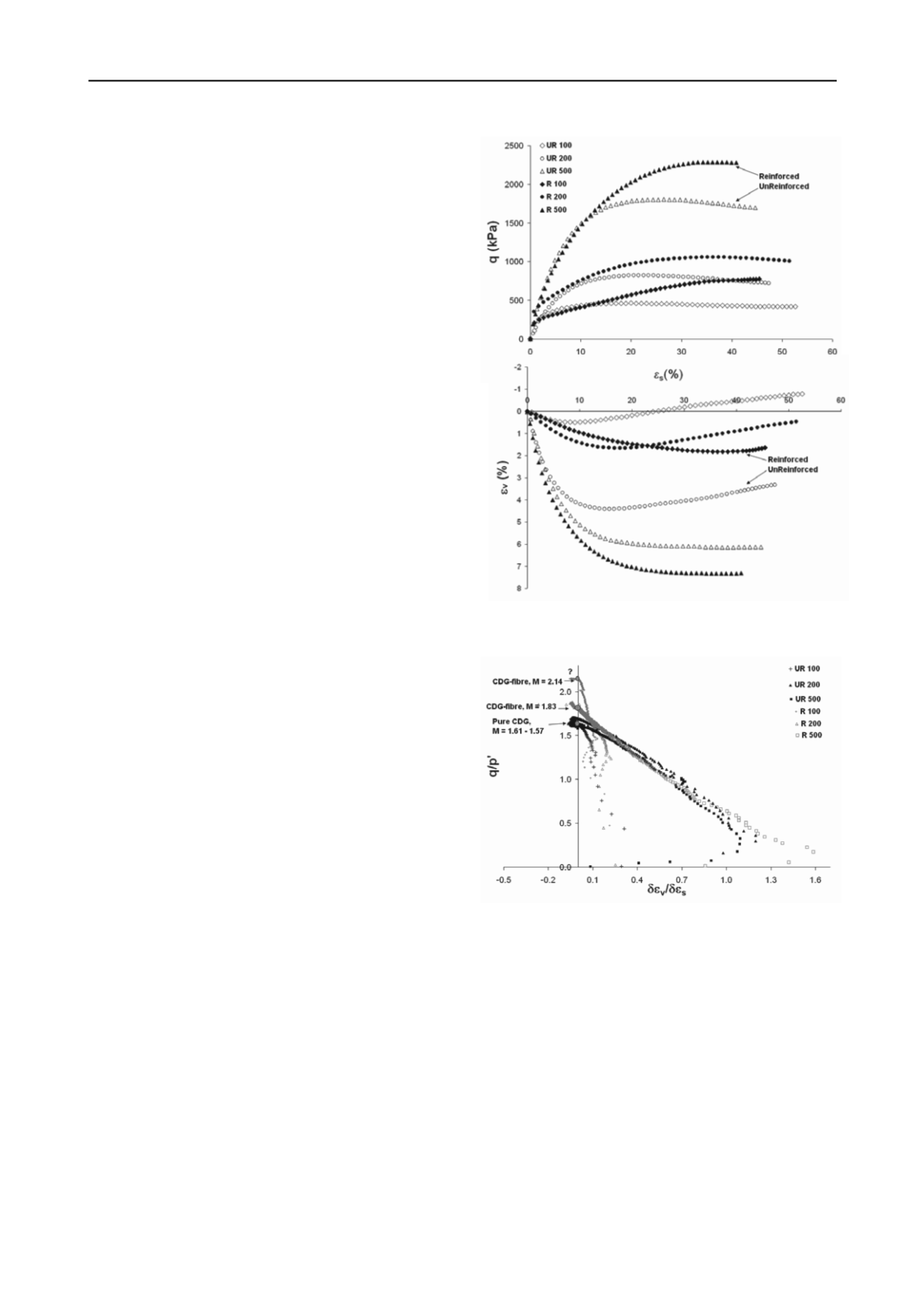

strength and higher initial stiffness at the beginning of shearing,

when compared to their unreinforced counterparts. However the

reinforced specimens that mobilised their full strength only did

so at shear strains in excess of 20%. The unreinforced

specimens on the other hand either reached a constant stress by

20% strain or they showed strain-softening, depending on their

consolidation history. Unlike the other reinforced specimens,

R100 kept gaining strength and never reached critical state even

at large strains (about 50%). This may be due to the over-

consolidation history of the specimen, which may have released

some of the tension in the fibres prior to shearing. The peak

strengths of reinforced CDG were calculated to be 1.76

(100kPa), 1.29 (200kPa) and 1.26 (500kPa) times that of the

pure CDG.

Similar behaviour on fibre-reinforced sands is reported by

Consoli

et al.

, 2007, Consoli

et. al

(2005) and Silva dos Santos

et al

. (2010). For example Silva dos Santos

et al

. (2010) found

that the effect of fibres depends on the effective stress at which

they are sheared, reducing marginally with increasing effective

stress. For sands, it is already reported that at low effective

stress, adding fibres contributes to reducing the degree of

dilation in the reinforced specimens (Silva dos Santos

et al

.,

2010). The persistent strain hardening behaviour (figure 3a,

R100) was also observed by Consoli

et. al

(2005) on Botucatu

residual soil, however their data were limited to strains of about

25%. In the present study, the specimens were sheared to strains

up to 50% and it is clear that the strain hardening behaviour of

specimens R200 and R500 stopped beyond

s

>35% to reach a

critical state. The governing mechanism for the strain hardening

behaviour of R100 specimen might therefore be due either to

the effect of low effective stress or to the effect of over-

consolidation, or a combined effect.

The effect of the fibres on the volumetric response of the

reinforced CDG in comparison seems to be that of restricting

the degree of dilation in the specimen sheared at lower effective

stresses, while at higher effective stress this effect is not so

evident (figure 3b). The over-consolidated specimen of

reinforced CDG shows a different volumetric response i.e. it

tends to dilate after 20% shear strain even though it is expected

that reinforcement will impede dilation. This behaviour is again

either due to over-consolidation or to low effective confining

stress. Previous findings on Botucatu residual soils (Consoli

et.

al,

2005) and other pure sands may be extrapolated to normally

consolidated CDG, but the effect of over-consolidation is new

and more test results are required to explain it within the critical

state framework.

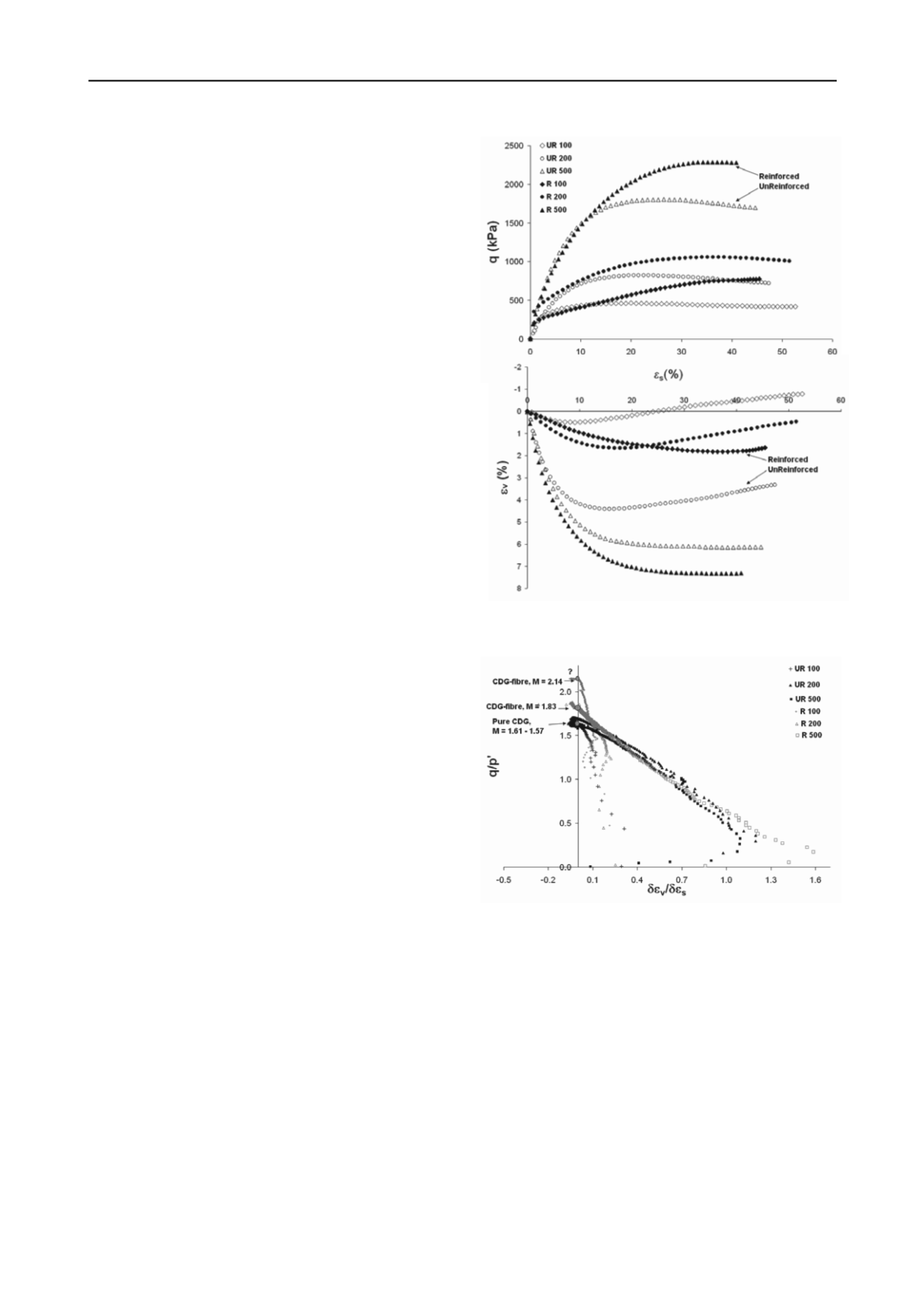

The stress-dilatancy behaviour of CDG (black symbols) and

reinforced CDG (grey symbols) samples tested at different

effective stress are shown in figure 4. All normally consolidated

specimens, reinforced and unreinforced, show a typical

frictional behaviour. The pure CDG specimens converge to a

unique critical state stress ratio ranging from

M

=1.57 to

M

=1.61. The reinforced CDG specimens tested at effective

stresses of 200 and 500kPa converged to a critical stress ratio of

M

= 1.83. For the lower effective stress of 100kPa (R100), the

specimen reached a higher stress ratio of

M

= 2.14, which is

similar to what was found by Silva dos Santos

et al

. (2010) on

fibre-reinforced sand. The over-consolidated specimens, UR100

and R100, did not follow the frictional trend but showed much

less volumetric deformation up to critical state, which was also

observed in the stress-strain behaviour. This may have been

caused by locking of the fibres during compression and swelling

prior to shearing.

(a)

(b)

Figure 3. Stress-strain-volumetric response of CDG and fibre-

reinforced CDG sheared at different effective confining stresses.

Figure 4. Stress-dilatancy response of CDG and fibre-reinforced

CDG.

The deviatoric stress and corresponding mean effective

stress in the test that reached a stable critical state are plotted in

a q-p

'

plane in figure 5. These points form a critical state

envelope for the pure CDG with a critical state gradient

M

=1.57. This is found to be consistent with critical stress ratio

M

= 1.57 - 1.61, obtained from the stress-dilatancy plot (figure

4). The end of test points are also plotted for the reinforced

specimens but no attempt has been made in this paper to define

the critical state envelop for fibre-reinforced CDG because at

low stresses, the deviatoric stress does not stabilise (figure 3a).

More tests are required over a larger range of stresses to do so,

as was done by Silva dos Santos

et al

. (2010) who found that

the critical state lines of the unreinforced and reinforced

specimens converge at large stresses of the order of 5MPa.