2547

Technical Committee 211 /

Comité technique 211

Unit

weight

γ

t

(kN/m

3

)

Effective

cohesion

c'

(kN/m

2

)

Effective

angle of

friction

φ'

(deg.)

Deformation

modulus

E

(kN/m

2

)

Initial

void

ratio

e

0

Consolidation

yield stress

p

c

(kN/m

2

)

Compression

index

λ

Expansion

index

κ

Critical

state

parameter

M

Poisson’s

ratio

ν

Coefficient

of

permeability

k

(cm/sec)

Embankment 19.0

10.0

35.0

28,000

-

-

-

-

-

0.25

1.00×10

-3

Ac1-2

14.6

10.0

36.4

1,720 2.13

36.8

0.289

0.029

1.48

0.35

1.30×10

-6

As2

18.7

-

-

28,000

-

-

-

-

-

0.25

1.00×10

-3

Ac2-2

14.3

10.0

36.2

6,380 2.53

146.1

0.665

0.067

1.47

0.35

3.00×10

-7

Ac2-3

15.1

10.0

33.0

7,130 2.00

178.5

0.408

0.041

1.33

0.35

2.30×10

-7

Dvc

15.8

10.0

33.0

6,510 1.21

215.7

0.149

0.015

1.33

0.35

1.40×10

-9

Dvs

19.0

-

-

70,000

-

-

-

-

-

0.35

1.00×10

-3

Columns

19.0

-

-

367,000 –

718,000

*1

-

-

-

-

-

0.20

1.40×10

-9

-

1.00×10

-3*2

*1 The deformation modulus of thedeep mixing columns was derived from quality verification tests, which reduced dependence on the improvement

ratio.

*2 The coefficients of permeability of the deep mixing columns are same as those for each layer.

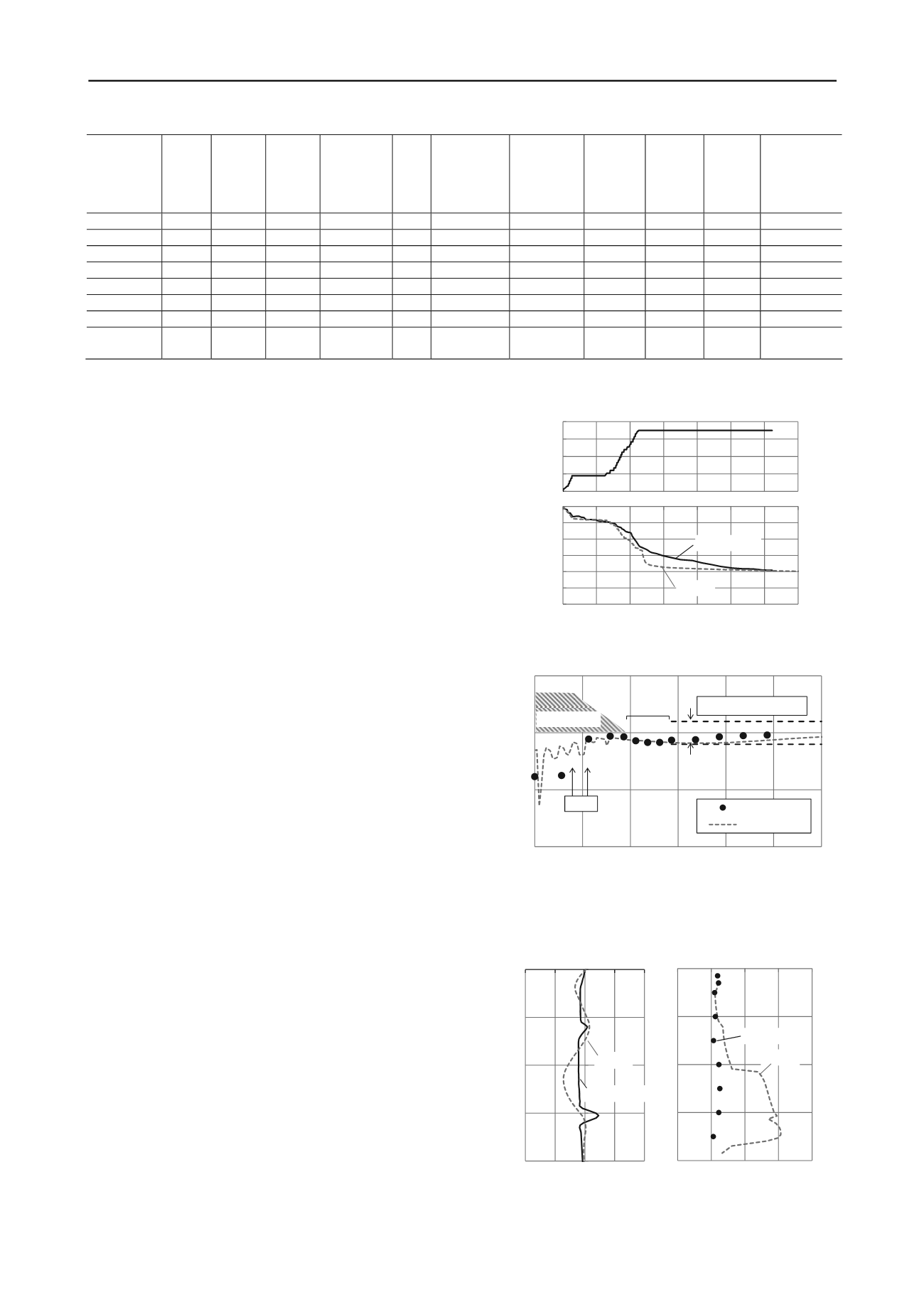

toe to the lateral boundary is 80m. As a boundary condition of

deformation, the bottom surface was fixed. The side surface was

free verticallyand fixed horizontally.As a drainage condition,

excess pore water pressures at the ground surface and bottom

surface were set to zero.

The soil layer is modeled as an elasto-plastic material using

the Sekiguchi-Ohta model (Sekiguchi and Ohta 1977). The sand

layers and deep mixing columns are modeled as a linear elastic

material. The embankment is modeled as an elasto-plastic

material using the Mohr-Coulomb model. Table 1 lists the

model parameters used for the analysis.

The history of the embankment construction was modeled

bybuilding up the elements. In converting from actual three-

dimensional ground to the two-dimensional numerical model,

the deformation modulus of the deep mixing columns was

reduced according tothe improvement ratio and the coefficient

on permeability for deep mixing columns was set to thevalue for

each layer of ground.

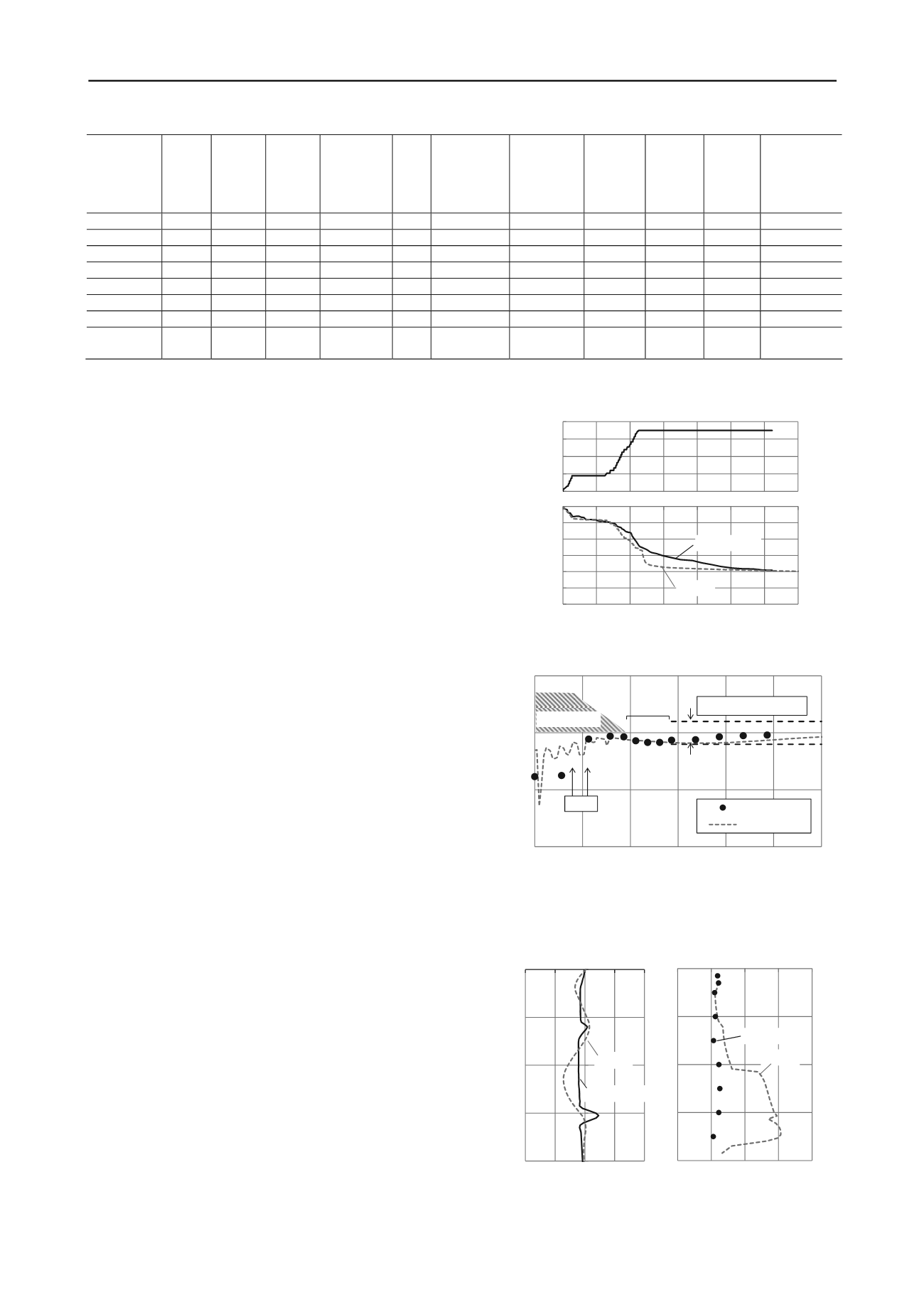

The following figures are for the sake of comparison and

analysis: Figure 6 shows the history of ground-surface

settlement at the center of the embankment; Fig.7 shows the

distribution of ground-surface settlement after construction of

the embankment; Fig. 8 shows the horizontal displacement and

vertical strain of the walls. The settlement history and

displacement of the ground surface and walls are quantitatively

evaluated using two-dimensional analysis. However, a clear

difference in the vertical strain exists at greater depths. In the

numerical models, the deformation modulus of wallsless than 21

m in height is lower than that of walls greater than 21m in

heightas perthe arrangement of the deep mixing columns. This

is thought to be the cause of the difference in vertical strain.

Individual material propertiesare effective for evaluating the

strain distribution of walls.

4 DETERMINING THE OPTIMUM ARRANGEMENT OF

DEEP MIXING COLUMNS

In this method, the piles and walls are effectively arranged

according to the limit values of deformation in the embankment

and the adjacent area. Due to the countless combinations of

planar arrangements and improvement depths, arbitrary

parametric studies require considerable time to identify

optimum arrangement. Therefore,the following3-step method is

proposed fordetermining the optimum arrangement.

1) Determine the planar arrangement: First, walls are placed

in the ground under the edges of the embankment crown. Next,

inside and outside piles are arrangedequidistantly by an amount

not less than the necessary improvement ratio α, defined as

α=γ

H/

q

uck

(1)

0

2

4

6

8

0

50

100

150

200

250

300

0 100 200 300 400 500 600 700

Elapsed days (day)

Analysis

Measurement

Height of

Embankment (m)

Settlement of

Embankment (mm)

Figure 6.Settlement history of ground surface in center of the

embankment

‐100

0

100

200

0

10

20

30

40

50

6

Distance from center line of embankment (m)

0

Measurement

Analysis

Walls

Limit value

:±

20mm

Embankment

10m

Settlement after construction

of embankment (mm)

Figure 7.Distribution of ground surface settlement after construction of

the embankment

‐40

‐30

‐20

‐10

0

‐40 ‐20 0 20 40

Depth (m)

Analysis

Measurement

(a)

Horizontal displacement of walls after

construction of embankment (mm)

‐1500

‐1000

‐500

0

500

Analysis

Measurement

(b)

Vertical strain of walls after

construction of embankment (με)

Figure 8.(a) Horizontal displacement of walls (b) Vertical strain

in walls