2550

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

diameter along the column depth. figure 1 shows the nowadays

available original and modified improved springsol

tool. the

folded tool is of a diameter of 150 and 165 mm for the original

and modified version respectively.

some of the advantages of the method are:

-

no pollution of the subgrade layer with the cement

slurry, due to insertion of the casing that enables the

recovery of spoil.

-

the spoil collection with the system installed at the

base of the mast of the drilling rig, connected to the

peristaltic pump drawing the spoil directly to the

container.

-

the high production rate.

-

Working under difficult execution conditions and

limitations, i.e. under low headroom conditions and

within reduced spaces.

-

execution with small batching plants and small drilling

rigs in reduced limited spaces, etc.

the quality of soil-cement columns regarding their

homogeneity and strength is influenced by two parameters:

-

im (rev/m) - blade rotation number determining the

mixing efficiency defined as a total number of mixing

blades passing along one meter of tool penetration, and

-

ii (kg/m

3

) - cement quantity introduced per m

3

of the

treated soil.

table 1. springsol

columns performance and geo-mechnaical

arameters.

p

parameter

diameter (mm)

400-700

Water / cement ratio

0.6-1.2

penetration velocity (cm/min)

15-50

im (rev/m)

min 350

ii (kg/m

3

)

150-350

Ucs (mpa)

0.5-6.0

e

50

(50-500) Ucs

shear strength

20-40% Ucs

Bending strength

8-15% Ucs

the general execution parameters and geo-mechanical

characteristics (unconfined compressive strength - Ucs,

stiffness modulus – e

50

, shear and bending strength) of the soil-

cement columns executed by the springsol

device are given in

table 1. these data are established on experiences gained on

different projects and field tests carried out recently in spain

(melentijevic et al 2012, melentijevic et al 2013). these

findings on geo-material properties are in agreement with

worldwide published information on deep mixed columns

(Bruce 2001, cdit 2002, etc.).

3 proJect details and adopted GroUnd

improVement solUtion

in this chapter an example of application of the springsol

technique for underpinning is presented. the industrial building

in the central spain presented different post-constructive

pathologies regarding differential settlements of floor slabs and

pavements as a consequence of poorly compacted anthropic fill

material. the main structure (walls and columns) were founded

on a natural ground, and due to its adequate geotechnical

characteristics did not present any pathology. the shallow

foundation on a natural ground was performed after a massive

excavation of superficial layers of natural soil, applying the

same material for construction of a fill without its appropriate

compaction.

the affected area included more than 8000 m

2

with the

installation of more than 2500 soil-cement columns. the length

of soil-cement columns ranged from 5.50 m to 8.00 m in

function of the thickness of the man-made fill, with the total

length of columns of more than 15000 meters. due to the form

of the springsol

tool, the columns were embedded

approximately 20 cm in the natural ground. the columns of a

400 mm diameter, performed with the originally developed tool,

were distributed in a square grid pattern ranging from 1.50 m to

2.00 m in function of the surcharge to be transmitted from the

slab. the performed solution is schematically presented in

figure 2.

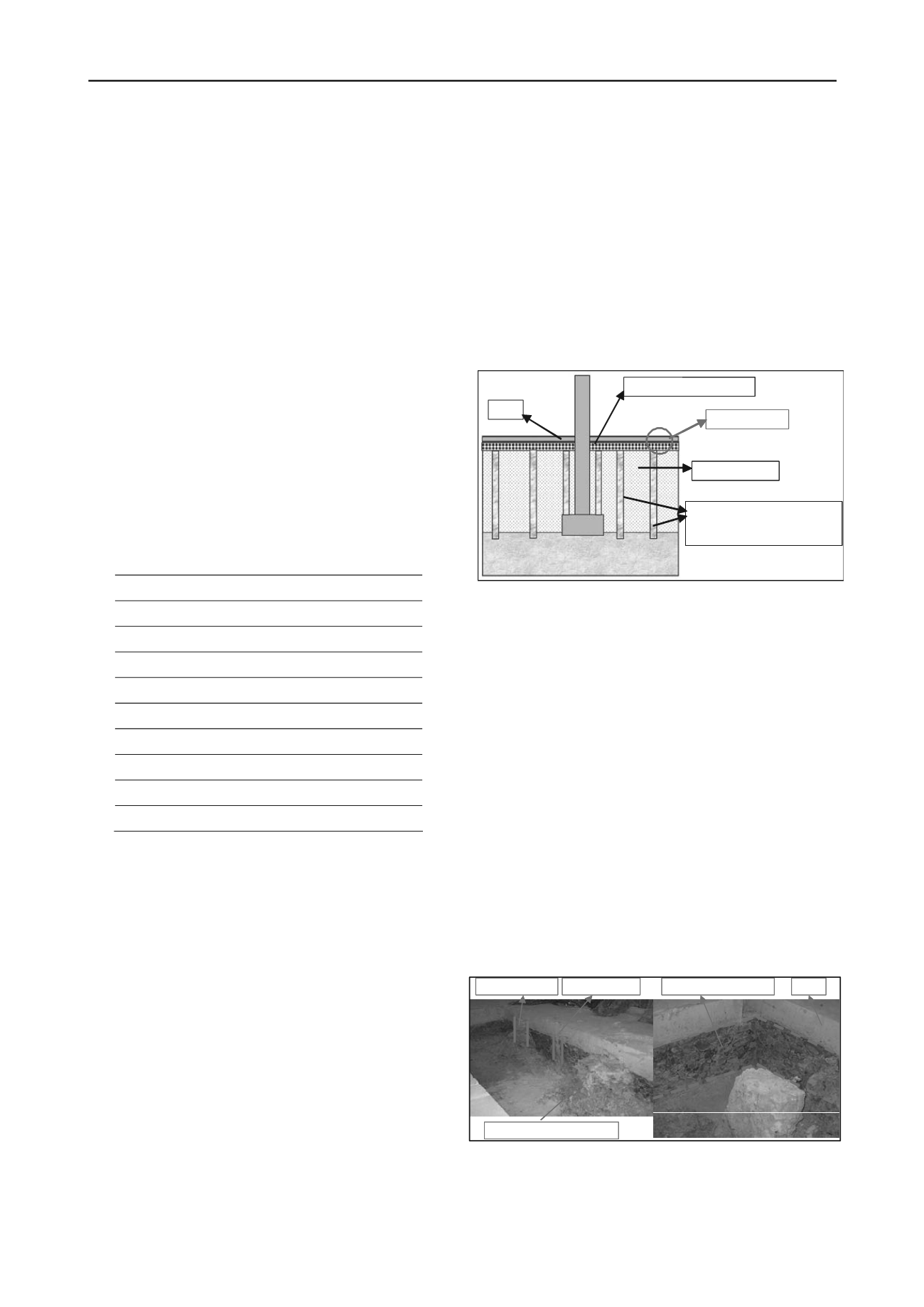

Slab

Springsol columns Ø400mm

Length = 5.50–8.00m

Grid=1.50x1.50m 2.00x2.00m

Man made fill

Natural soil-clays with

gravel and boulders

Grouting gap slab-fill

figure 2. cross section of the ground treatment solution.

the post pathology site investigation consisted of 46

dynamic penetration tests and 5 drilled boreholes with standard

penetration tests, executed from the working platform, i.e. the

existing floor slab level. the natural ground, detected at the

depth of 5.50 to 8.00 m from the surface, consisted of clays of

high consistency with gravels and boulders, with the n

20

>40

(dpsh). the overlaying treated loose man made fill was

formed of clays with gravels (n

20

<10) proceeding from the

natural ground after a massive excavation for the foundation of

the main structure elements.

the soil treatment solution included following steps:

-

coring of the existing slab (diameter = 62 mm) for

grouting of the gap between slabs and fill.

-

contact grouting between the slab and the fill in order

to fill gaps due to settlement of badly compacted man

made fill.

-

coring of the existing slab and contact grouted gap

(diameter = 182 mm) for the passage of the spreadable

tool.

-

execution of springsol

columns (diameter = 400 mm).

-

filing the gaps of coring the existing slab.

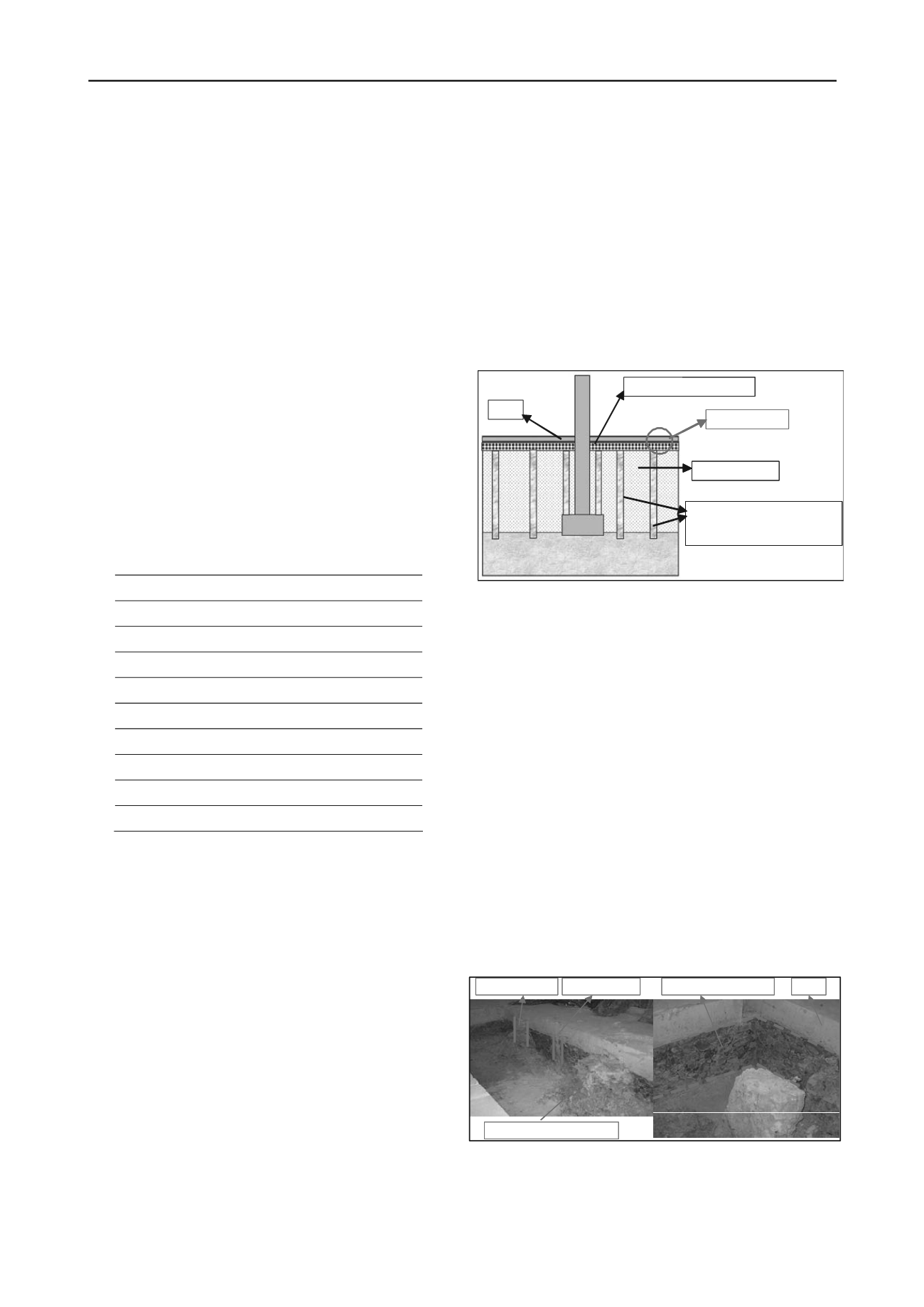

Visual description of the executed steps previously

mentioned is shown in figure 3.

figure 3. Visual control of the excavated treatment area.

see Figure 3

Slab

Grouting gap slab-fill

Coring 62 mm

Coring 182 mm

Springsol columns 400 mm