2542

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

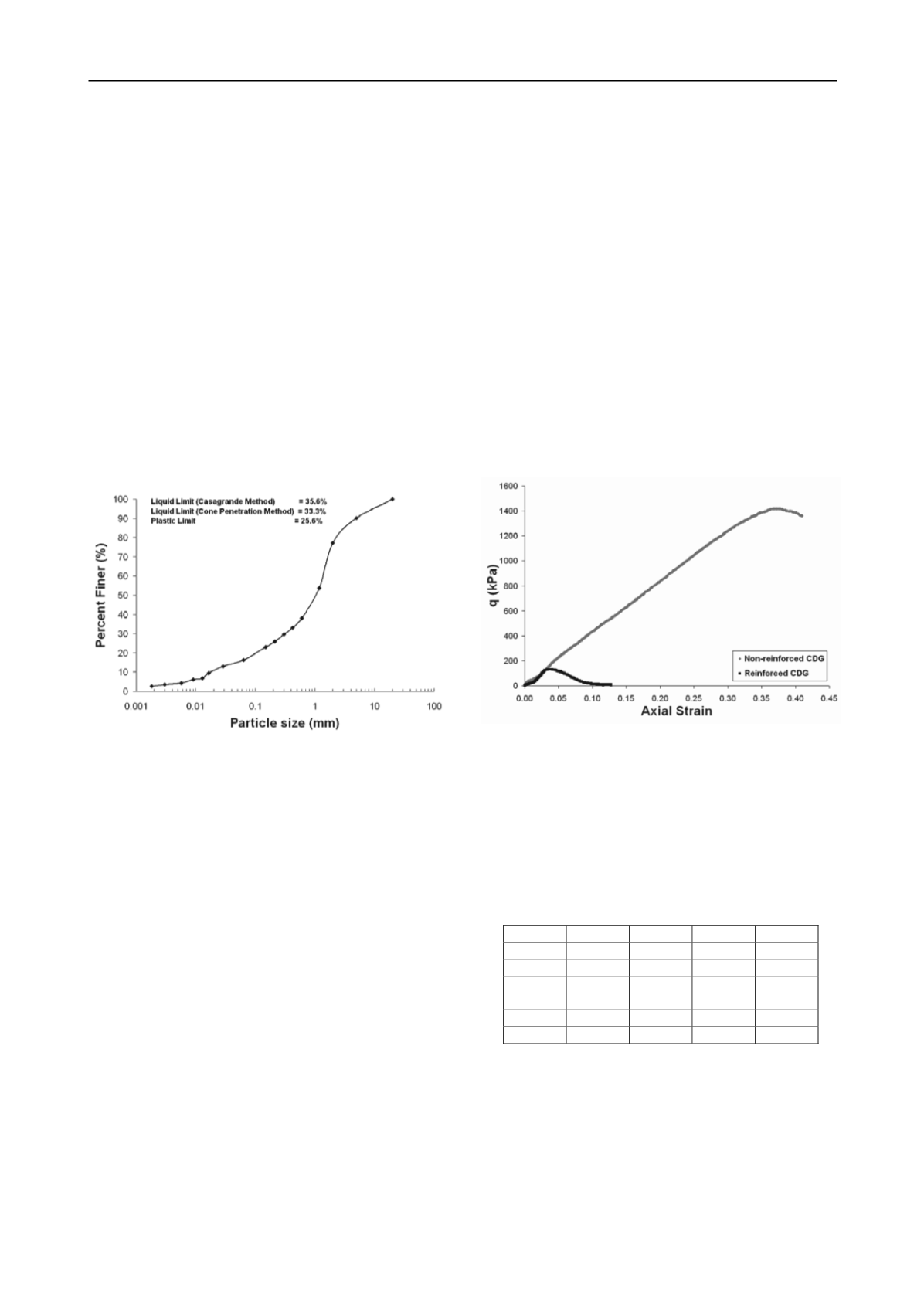

kaolinite and feldspar (Yan and Li, 2012). The grain size

distribution (shown in figure 1) reflects that the soil has 16%

particles finer than 63

. The specific gravity of the soil was

found to be 2.65. From Standard Proctor compaction tests, the

maximum dry density of the soil was determined as 1.93Mg/m

3

with an optimum moisture content of 12.3%. Tests on particles

finer than 425μ indicated the plastic and liquid limits to be

25.6% and 35.6% respectively. Using the Unified Soil

Classification System (USCS) the soil can be classified as

clayey sand of low plasticity (SC-CL).

The fibres used are short filaments made of polypropylene

similar to those used by Silva dos Santos

et al

. (2010). They are

chemically inert and have uniform characteristics, with a

relative density of 0.91, a tensile resistance of 120MPa, an

elastic modulus of 3GPa and a range of linear deformation at

rupture between 80% and 170%. The dimensions of the fibres

used in the tests were 0.023mm in diameter and 24mm long

(Silva dos Santos et al., 2010). After performing a series of

unconfined compression tests on CDG reinforced with a range

of fibre contents (0.3 – 1%), it was decided to continue the

study with 0.3% of fibre per weight in the triaxial tests.

Figure 1. Particle size distribution of CDG.

2.2

Testing apparatus, methods and sample preparation

2.2.1 Uniaxial Compression Test

Unconfined compression tests on CDG and CDG+fibre soils

were performed in a uniaxial compressive testing machine. The

particle sizes passing 2mm diameter sieve were used for

preparing specimens in a 38mm diameter; 76mm height mould

at maximum dry density and optimum moisture content. The

compression tests were performed at 0.5mm/min in all cases.

2.2.2 Triaxial Testing

Drained triaxial tests were performed using a conventional

triaxial apparatus with a computer controlled GDS cell and back

pressure controllers. The shearing tests were performed with a

constant effective stress on specimens of both unreinforced and

reinforced (with polypropylene fibres) CDG soil.

The soil was first soaked in water with a deflocculating

agent and left for air drying, then it was sieved to constituent

particle sizes so that the samples could be prepared in exact

proportion as shown in figure 1, discarding particles above

5mm. Loose specimens were prepared, avoiding macro-voids

and taking care of minimising membrane penetration. The

specimens of 76mm diameter and 152mm height were prepared

in a sample preparation mould.

The samples were saturated under back pressure and the

effective confining pressures ranged from 100 to 500kPa.

Saturation was monitored in each test, ensuring Skempton

B

values of at least 0.92 throughout the testing programme. The

axial strains were measured outside the cell using a standard

displacement transducer. The triaxial tests were run at a low

axial strain rate of 0.01% per minute to ensure no excess pore

pressure development within the sample (this was checked by

measurement at the opposite end of specimen). The membrane

and area corrections were made as per the recommendations

proposed by La Rochelle et al. (1988). The void ratios are

calculated averaging from that obtained by the initial density of

the sample and the final moisture content, taking account of the

measured volume change in all the stages. In all tests the

difference in specific volume compiled was less than 0.02.

3 TEST RESULTS

3.1 Unconfined compressive strength

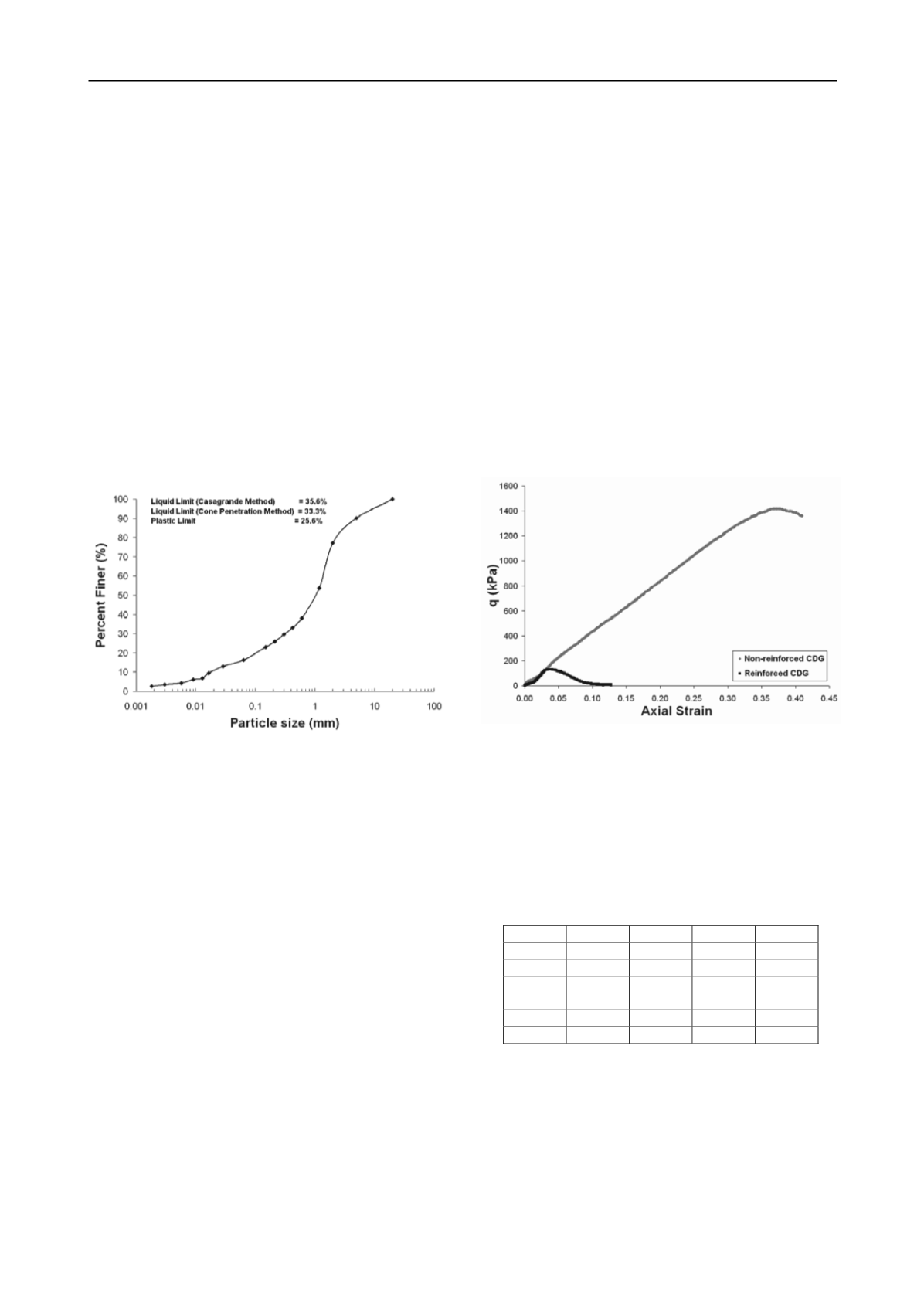

Representative unconfined compression test results on pure

CDG and CDG + 0.5% fibre are presented in figure 2. The plot

clearly shows that the specimens of reinforced CDG yielded at

very high strain, contributing an additional tenfold strength to

the soil. On the other hand unreinforced CDG yielded at very

low strength (131kPa) and low strain.

Figure 2. Unconfined compression of CDG and fibre-reinforced

CDG.

3.2 Triaxial shearing

Triaxial drained tests were performed on isotropically

consolidated specimens of pure CDG and reinforced CDG

(Table 1). Some specimens were over-consolidated by a ratio of

OCR=5 before being sheared. Details of the tests are shown in

Table 1 (UR and R refer to unreinforced and reinforced

specimens respectively).

Table 1. Summary of the triaxial tests.

Test

v

0

v

c

p

c

'

(kPa)

OCR

UR 100

1.42

1.32

112.0

5

UR 200

1.42

1.37

210.4

1

UR 500

1.48

1.32

499.6

1

R 100

1.58

1.36

98.9

5

R 200

1.43

1.32

202.9

1

R 500

1.58

1.41

499.4

1

The void ratios determined after consolidation (before shearing)

were found to vary between 0.32 and 0.37 for pure CDG

specimens and 0.32 and 0.42 for CDG-fibre specimens. Only

dense specimens were prepared for the test programme. Looser

specimens were difficult to prepare due to the presence of

macro-voids which caused an initial collapse of the specimen,

resulting in void ratios after consolidation within the same range

as those for the dense specimens.

The stress-strain and volumetric responses during shearing

are shown in figure 3. The stress-strain response (figure 3a)

shows that the reinforced specimens generally have higher