2544

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

6 REFERENCES

Altuhafi F.N. and Coop M.R. (2011). Changes to particle

characteristics associated with the compression of sands.

G

é

technique

61, No. 6, 459–471.

BS 1377:1990. Methods of test for soils for civil engineering

purposes. British Standards Institution, London

Consoli N.C., Casagrande M.D.T. and Coop M.R. (2005).

Effect of fiber reinforcement on the isotropic compression

behavior of a sand.

J. Geotech. Geoenviron. Engng, ASCE

131, No. 11, 1434–1436.

Consoli N.C., Heineck K.S., Casagrande M.D.T. and Coop

M.R. (2007). Shear strength behavior of fiber-reinforced sand

considering triaxial tests under distinct stress paths.

J.

Geotech Geoenviron. Engng , ASCE

133, No. 11, 1466–1469.

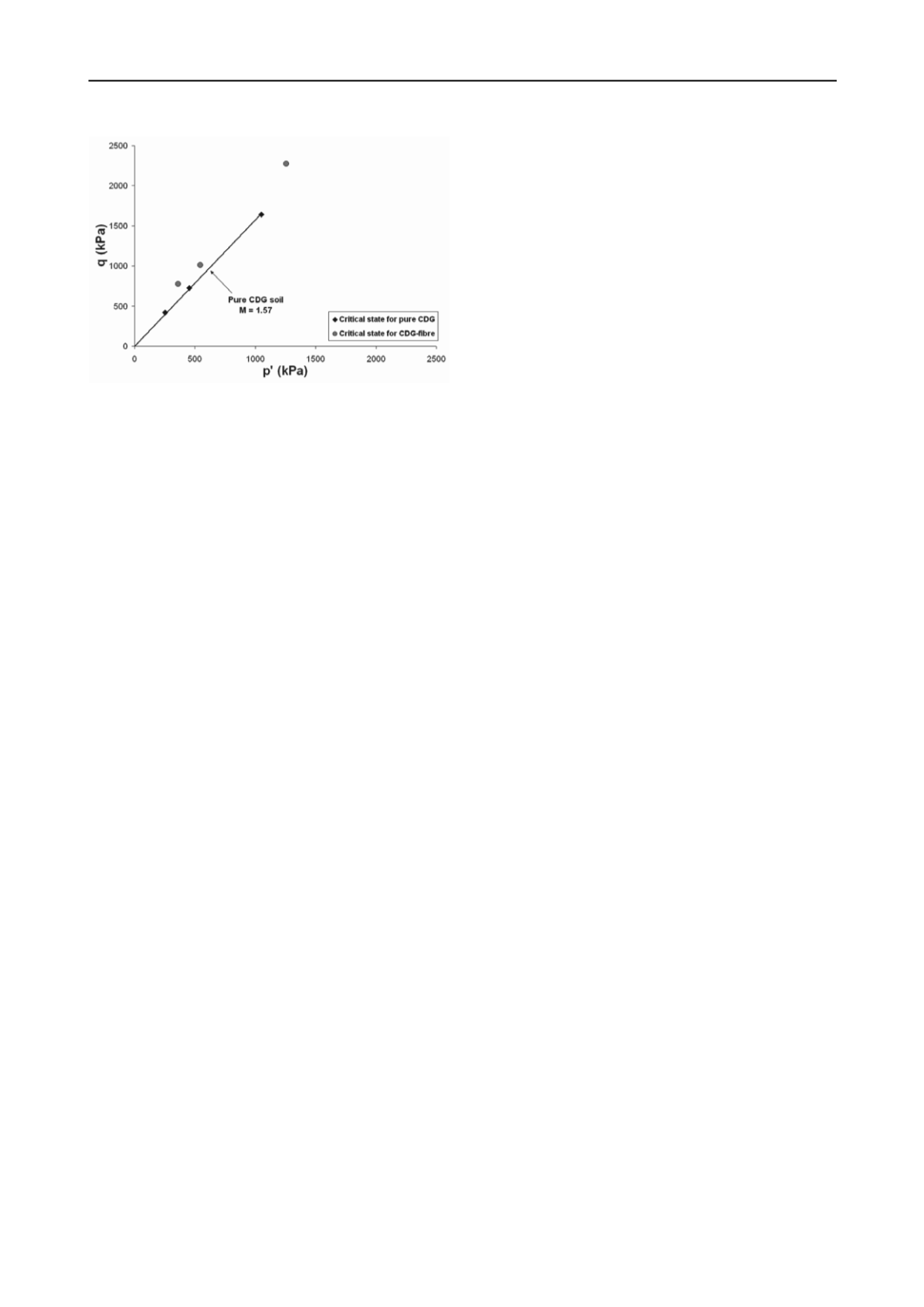

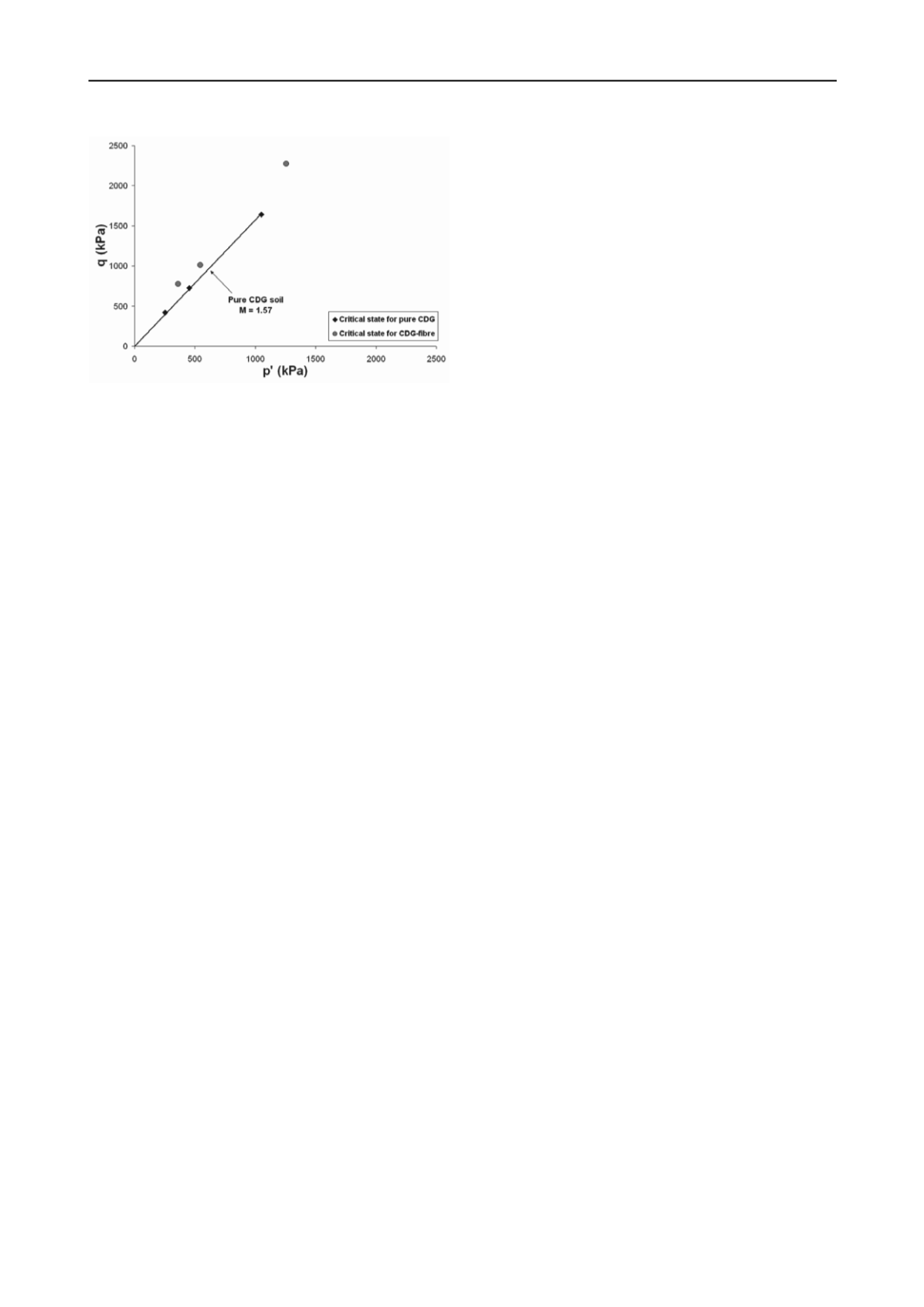

Figure 5. Critical states and end of test points for CDG and

fibre-reinforced CDG in q-p

'

plane.

Consoli N.C., Casagrande M.D.T., Thomé A., Dalla Rosa F.

and Fahey M. (2009a). Effect of relative density on plate tests

on fibre-reinforced sand.

Géotechnique

, 59, No. 5, 471–476.

4 CONCLUDING REMARKS

The results presented indicate that using discrete fibres can be

an effective means of reinforcing CDG, specifically at low

effective stresses. The unconfined compressive strength tests

showed a tenfold increase in strength with 0.5% fibres content

in the soil prepared at maximum dry density and optimum

moisture content. In triaxial drained tests, adding fibres seems

to increase the shear strength by up to two times the strength of

the unreinforced specimens, as well as its initial stiffness.

Dilation was also found to be reduced. Unique critical states

were reached for the unreinforced CDG and reinforced CDG

tested at high effective stress. The stress-dilatancy was found to

be frictional for all normally consolidated specimens, but with

different critical state stress ratios (

M

) for the fibre-reinforced

specimens depending on their effective confining stress. Initial

results also seem to indicate that the over-consolidation ratio

affects the performance of the reinforced CDG, noticeably in

the stress-dilatancy response, but more work is needed to

confirm it.

Consoli N.C., Festugato L. and Heineck K.S. (2009b).

Strainhardening behaviour of fibre-reinforced sand in view of

filament geometry.

Geosynthetics Int.

16, No. 2, 109–115.

Crockford W.W., Grogan W.P. and Chill D.S. (1993). Strength

and life of stabilized pavement layers containing fibrillated

polypropylene.

Transpn Res. Rec.

1418, 60–66.

Gray D.H. and Al-Refeai T. (1986). Behavior of fabric versus

fiber reinforced sand.

J. Geotech. Engng, ASCE

112, No. 8,

804–826.

Lee I.K. and Coop M.R. (1995). The intrinsic behaviour of a

decomposed granite soil.

Geotechnique

45 (1), 117–130.

Maher M.H. and Ho Y.C. (1994). Mechanical properties of

kaolinite/fiber soil composite.

J. Geotech. Engng, ASCE

120,

No. 8, 1381–1393.

Santoni R.L., Tingle J.S. and Webster S.L. (2001). Engineering

properties of sand–fiber mixtures for road construction.

J.

Geotech. Geoenviron. Engng, ASCE

127, No. 3, 258–268.

Silva Dos Santos A.P., Consoli N.C. and Baudet B.A. (2010).

The mechanics of fiber-reinforced sand.

Géotechnique

, 60,

No. 10, 791–799.

5 ACKNOWLEDGEMENTS

The authors wish to acknowledge Ku Hei Man, Gloria (final

year project student 2012, The University of Hong Kong) for

providing the Unconfined compressive test results. The

financial support provided by Hong Kong Research Grant

Council GRF No.70211 is gratefully acknowledged.

Yan W.M. and Li X.S. (2012). Mechanical response of

medium-fine-grained decomposed granite in Hong Kong.

Engineering Geology

129-130 (2012) 1–8.