2534

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

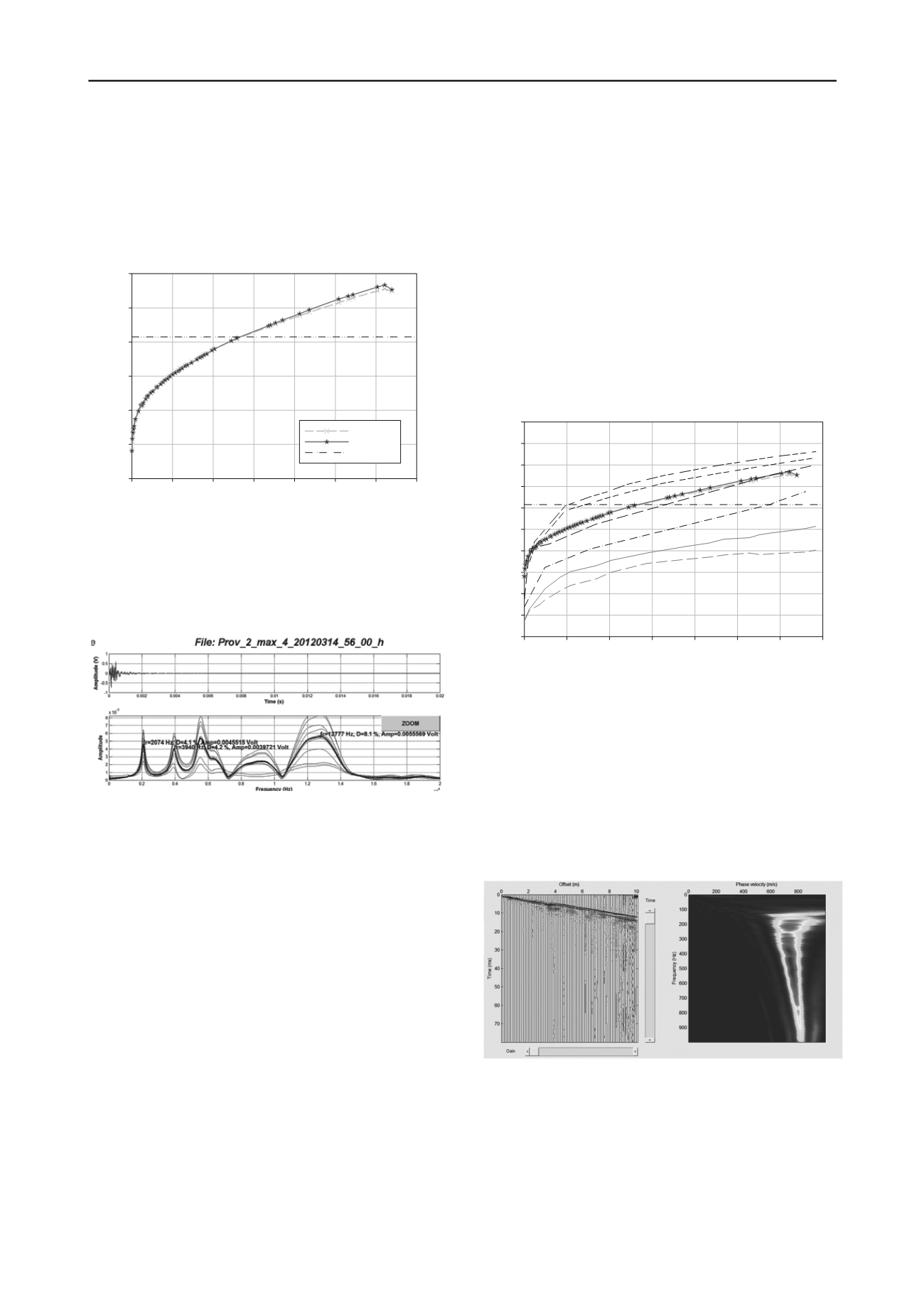

cement stabilised soils (rydén

et al.

, 2006).new samples were

prepared to measure the early strength development, see

figure 1.after more than 1200 hours the samples were removed

from the plastic mould that supported the samples during

compaction and in the beginning of the curingperiod of the

samples. this resulted in a small drop in p-wave velocity.

Curing time (h)

0

200

400

600

800

1000

1200

1400

P-wave velocity (m/s)

200

400

600

800

1000

1200

1400

1600

1800

2000

2200

PS 1

PS 1

PS 1

PS 1

PS 1PS 1

PS 1

PS 2

PS 2

PS 2

PS 2PS 2

PS 2

PS 5

PS 5

PS 5

PS 5

PS 5

PS 5

PS 5

PS 5

PS 5

PS 5

PS 6

PS 6

PS 6

PS 6

PS 6

PS 6

PS 6

PS 6

PS 6

PS 6

PS 9

PS 9

PS 9

PS 9

PS 9

PS 9

PS 9

PS 9

PS 9

PS 9 PS 9

PS 9 PS 9PS 9PS 9 PS 9PS 9PS 9

PS 11

PS 11

PS 11

PS 11

PS 11

PS 11

PS 11

PS 11

PS 11

PS 11 PS 11PS 11 PS 11PS 11PS 11 PS 11PS 11PS 11

Curing time (h)

0

200

400

600

800

1000

1200

1400

P-wave velocity (m/s)

600

800

1000

1200

1400

1600

1800

Sample 1

Sample 2

Limit

figure 1.the figure shows the development of compressive wave

velocity with time. the drop in velocity after 1240 hours is caused by

removing the samples from the plastic mould.

the seismic measurements of the prepared samples were

performed several times every 24 hours for the first 400 hours.

in figure 2 the measured frequency is shown together with

higher frequency modes.

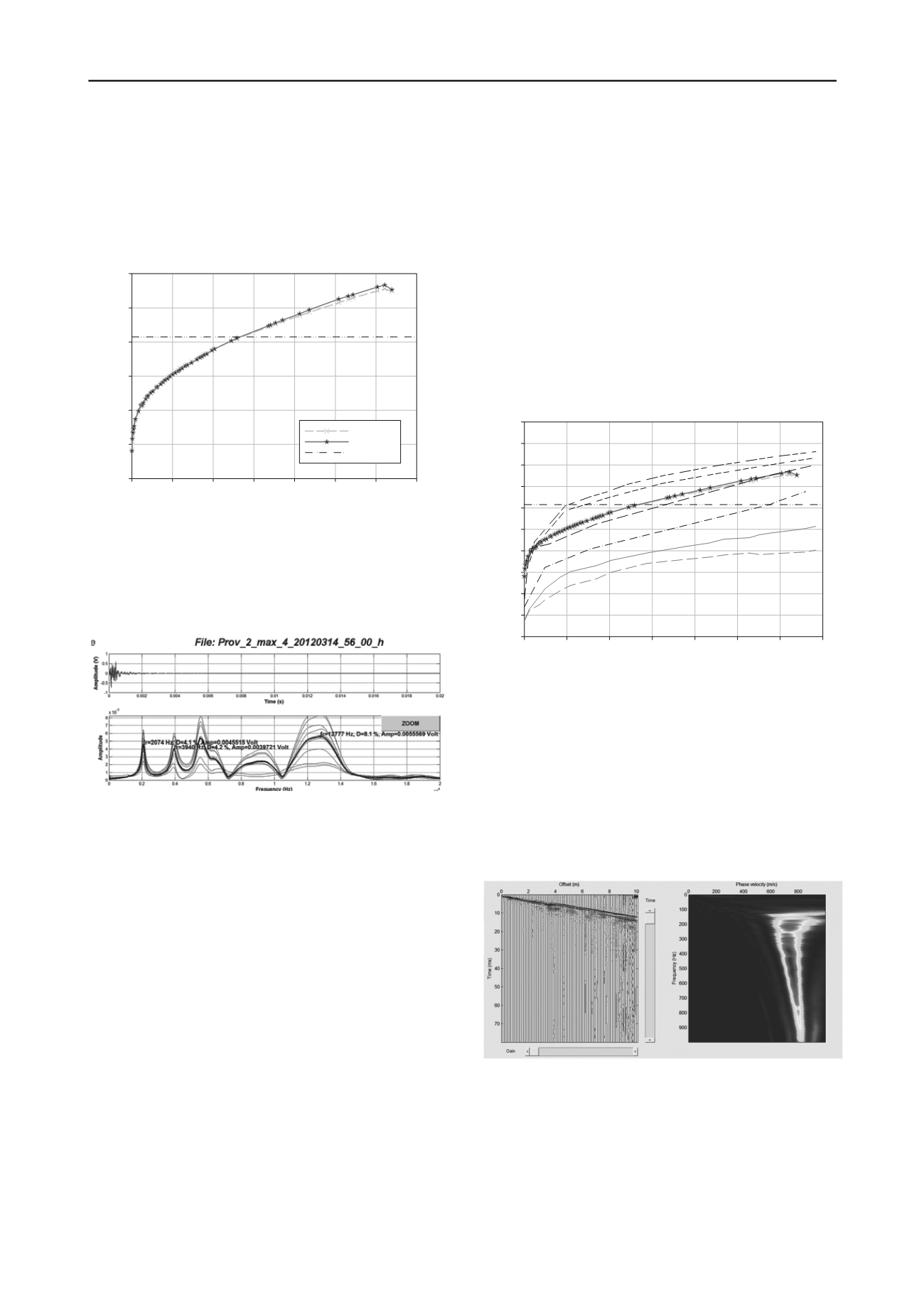

figure 2.different frequency modes for sample number 2 after 56

hourscuring. the lowest frequency peak corresponds to a fundamental

mode longitudinal resonance frequency of 2074 hz which corresponds

to a p-wave velocity of 1043 m/s.

the longitudinal resonance frequency of 2074

hzcorresponds to a p-wave velocity of 1043 m/s for sample 2.

the samples needed approximately 500 hours of curing in 20

degree celsius to meet the requirements regarding p-wave

velocity.

2 in-sitU measUrements

the quality testing in-situ was done both as ordinary testing

with binder content, mcV, pulverization and e

vib

measurement

with the compaction roller. the testing procedure also included

sampling from the stabilised soil when the mixer had made two

mixing passes. the stabilised soil that would be tested was

excavated and transported to a field laboratory for compaction

in plastic moulds. after compaction the p-wave velocity was

measured and compared with the laboratory mixed samples.

most of the production samples (ps) were stored in room

temperature to ensure the same conditions compared with the

laboratory compacted samples.

there was a great variation in the development of p-wave

velocity versus curing time for different samples, see figure 3.

the causes of this variation were a combination of different

Variation in grading (clay content)

in the figure. the sample ps 9 was

figure 3.development of compressive wave velocity with time for

ref

transfer is one

dim

e will affect the stabilised soil in-situ.

n example of the in situ seismic measurements is shown in

st

a

me

e

value of the stabilised soils’ performance. the seismic testing

will be followed up in future with testing on the concrete slab.

parameters such as;

Variation in water content

Variation in density

Variation in the degree of pulverization

in order to study the development of p-wave at different

temperatures two pairs of specimens were manufactured. one

pair was stored in room temperature and the other pair was

stored at outside temperature. the difference in p-wave

development is shown in figure 3. the different samples are

denoted ps9 and ps11

stored at room temperature and the sample ps 11 was stored at

outside air temperature.

erence and production samples.

the production sample denoted ps9 required more than

2400 hours achieving the limit value of 1430 m/s and the

sample ps 11 did not achieve the required limit. however,

storing a specimen in an outside air temperature is not fully

correct compared to the in situ conditions due to larger volume

of stabilised soil and in the in-situ case the heat

ensional. it does however give an idea of how low

temperatur

a

figure 4.

figure 4.a result from seismic in-situ measurement along the surface of

the stabilised layer is presented in the figure. the top layer has almo

re ched a surface wave velocity (~0.92Vs) of 800 m/s at the time for

asurement. the target shear wave velocity after curing is 900 m/s.

the in-situ measurement of the stabilised soil is performed

with the same equipment as used for sample testing. however,

the in-situ testing involves the whole volume and gives a tru