2524

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

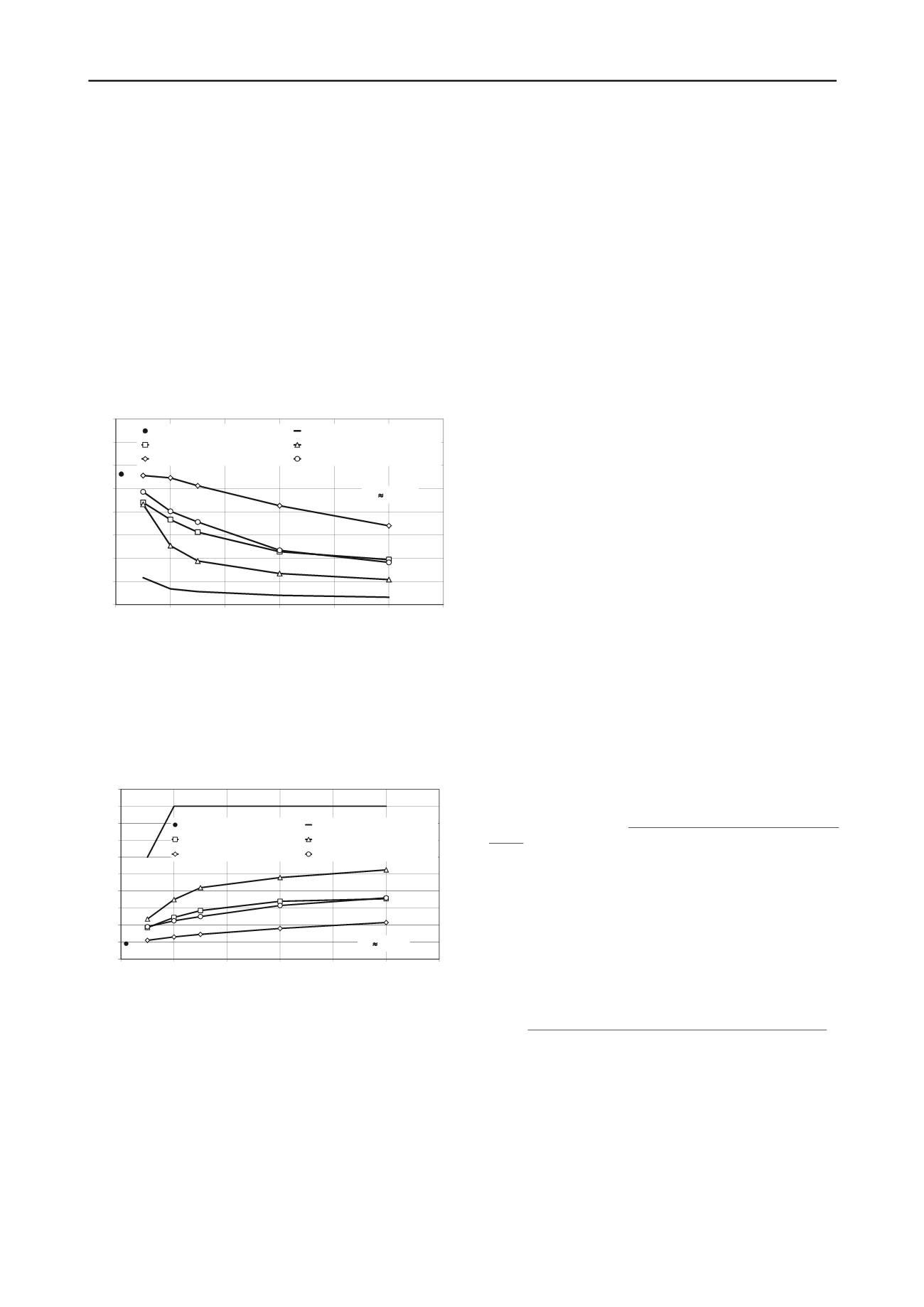

− 60-cm diameter column-type improvements reduce the

settlements linearly with increasing unconfined strength, but

not very markedly,

− 60-cm diameter columns are more effective in 2.0×2.0-m

grid spacing than in 3.0×3.0-m, although the settlements are

halved at

q

u

= 1 MPa for the larger grid as well,

− there is little difference between the reduction curves of the

60-cm diameter columns in 2.0×2.0-m grid spacing and of

the 1,8-m diameter equivalent columns made in 5.4×5.4-m

grid spacing,

− the improvement with 1,8 m diameter equivalent columns in

3.6×3.6 m grid spacing is dramatic, the settlements are

halved at about

q

u

= 0,2 MPa,

− total mass stabilization can be the most effective techno-

logy. Even for very small unconfined strengths (

q

u

= 0.1

MPa) the settlements are reduced to one-fourth.

0

5

10

15

20

25

30

35

40

0,0

0,2

0,4

0,6

0,8

1,0

1,2

settlement

s

[cm]

unconfined compressive strength

q

u

[MPa]

without treatment

mass stabilization

5.4×5.4 m square grid - d=1.8 m 3.6×3.6 m square grid - d=1.8 m

3.0×3.0 m square grid - d=0.6 m 2.0×2.0 m square grid - d=0.6 m

E

70

·

q

u

Figure 10. Calculated relationship between

s

- q

u

3.3 Stability analysis

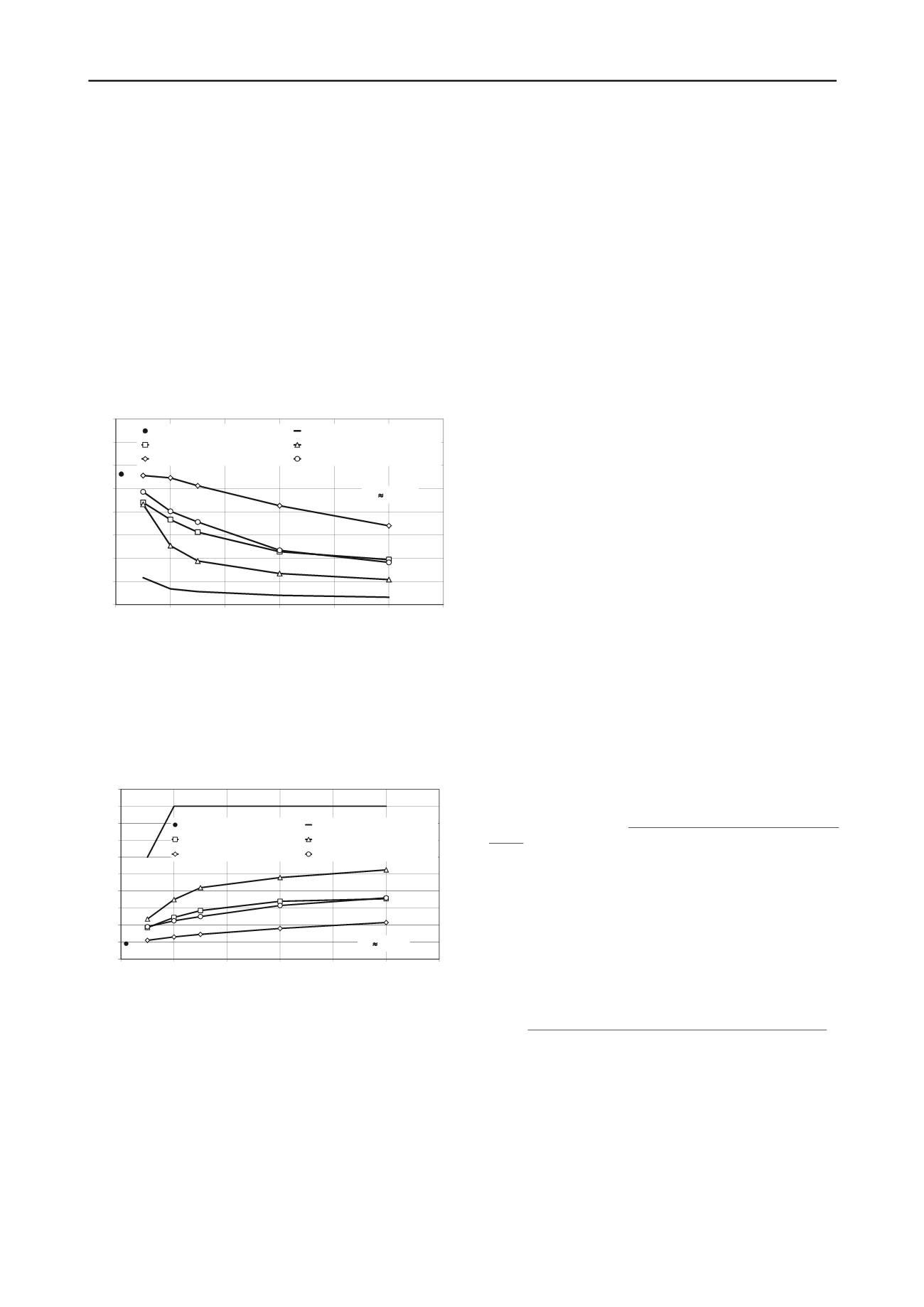

The influence on sliding stability was evaluated by plotting

safety factor as a function of unconfined strength (Figure 11.).

For untreated soil,

SF

=

1.18 and it could be significantly

increased with even a slight amount of treatment.

1,0

1,2

1,4

1,6

1,8

2,0

2,2

2,4

2,6

2,8

3,0

0,0

0,2

0,4

0,6

0,8

1,0

1,2

safety factor

SF

[-]

unconfined compressive strength

q

u

[MPa]

without treatment

mass stabilization

5.4×5.4 m square grid - d=1.8 m 3.6×3.6 m square grid - d=1.8 m

3.0×3.0 m square grid - d=0.6 m 2.0×2.0 m square grid - d=0.6 m

E

70

·

q

u

Figure 11. Calculated relationship between

S

F –

q

u

The results can be summarized in the following:

− the lines for different diameters and grid spacing are very

similar (except for mass stabilization),

− the four lines show that for

q

u

> 0.5 MPa, improvement is not

necessary,

− the 0.6-m diameter columns with 3-m grid spacing is the

least effective just reaching

SF

=

1.4 value with the

maximum strength investigated,

− the most effective technology to insure stability is the partial

mass stabilization. With 1.8-m diameter equivalent columns

and 3.6-m grid spacing, the required

SF

= 1.35 value can be

achieved with even small unconfined strength,

− the line for total mass stabilization shows a very different

behavior. It generates a high safety factor even for small

strength values, but quickly reaches a plateau. Beyond this

point the mechanics of the stability failure changes with the

failure surface travelling through the embankment slope

only.

4 CONCLUSIONS

For road and rail embankment foundations, soil improvement is

a frequently-used technique. Column-type deep-mixing and

mass stabilization are effective soil improvement technologies

to reduce settlements increase safety against slope failure. To

prepare new railway rehabilitation projects the usability of both

methods was investigated on a special soil type: chalky silt in

Sárrét (Hungary).

While the underlying chemistry may be complex, the

performance of the mixed material can be evaluated by standard

laboratory and field tests. Laboratory tests have clearly

demonstrated that the Sárrét chalky silt is suitable for

improvement by cement. While it cures relatively slowly, an

adequate strength is reached in about 40 days. Unconfined

strengths up to 1,0 MPa can be reached by adding relatively

small amounts of cement. Its uniform and predictable response

to treatment allows the engineer to design the field

improvement. For example, the relationship between

unconfined strength and total water-cement ratio can be

described with simple equations. The Young’s modulus of the

chalky silt can be calculated as 70 times the unconfined

strength.

Finite element modeling was used to study the effectiveness of

the mixing improvement. Column-type and mass stabilization

scenarios were analyzed using strength and compressibility

values from laboratory test results. Both technologies showed

reductions in settlement and increase in stability. Based on the

figures presented, the effectiveness of various solutions can be

evaluated at the first design stages easily and rapidly. Using the

trends from the figures, an optimal solution can then be arrived at

during the detailed design phase by making only some

calculations with PLAXIS for the actual design conditions.

In the future, a further refinement of the proposed method can

be achieved by assessing and involving the cost-effectiveness of

the alternatives in the design.

5 REFERENCES

Allu Stabilisation System,

-

system

Brinkgreve R.B.J., Vermeer P.A. (2010):

PLAXIS-Finite element code for

soil and rock analyses,

Plaxis 3D. Manuals, Delft University of Techno-

logy

Plaxis bv, The Netherlands.

Dumas, C. et. al. (2003):

Innovative Technology for Accelerated Const--

ruction of Bridge and Embankment Foundations in Europe,

FHWA-

PL-03-014, 2003, pp. 6-13.

Filz, G.M., Hodges, D.K., Weatherby, D.E. and Marr, W.A. (2005):

Standardized Definitions and Laboratory Procedures for Soil-Cement

Specimens Applicable to the Wet Method of Deep Mixing,

GSP 136

Innovations in Grouting and Soil Improvement, ASCE Geo-frontiers,

Reston, Virginia, pp.1-13.

Hayward Baker, (2010) Geotechnical Construction, Construction Tech-

niques,

Logar, J. (2012),

Ground Improvement State of the Art in South Eastern

Europe

, 2. Symposium Baugrundverbesserung in der Geotechnik am

13. und 14. September 2012 an der TU Wien, pp. 19-46.

Moseley, M.P., Kirsch, K. (2004):

Ground Improvement,

Taylor and

Francis, London, pp. 57-92, 331-428.