2516

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Nevertheless, below the embankment, there is no concrete slab

or rigid structure like for the foundation of the bridge.

Reinforced earth with galvanized steel was designed to hold the

large horizontal forces of active earth pressure. Because of the

large geotextile deformations during the consolidation period, as

shown in the following monitoring results, the decision was

made to use a stronger more rigid construction with nearly no

deformation. Compared with plastic geotextiles, the steel grid

material has only very small elastic deformations, and as a

result limiting the horizontal deformations of the embankment.

Through the addition of some gravel in parts of the sandy load

transfer platform LTP, the friction between LTP and CMC was

greatly increase and nearly no deformation was necessary to

mobilize the friction of the LTP.

5.2

Controlled Modulus Columns CMC

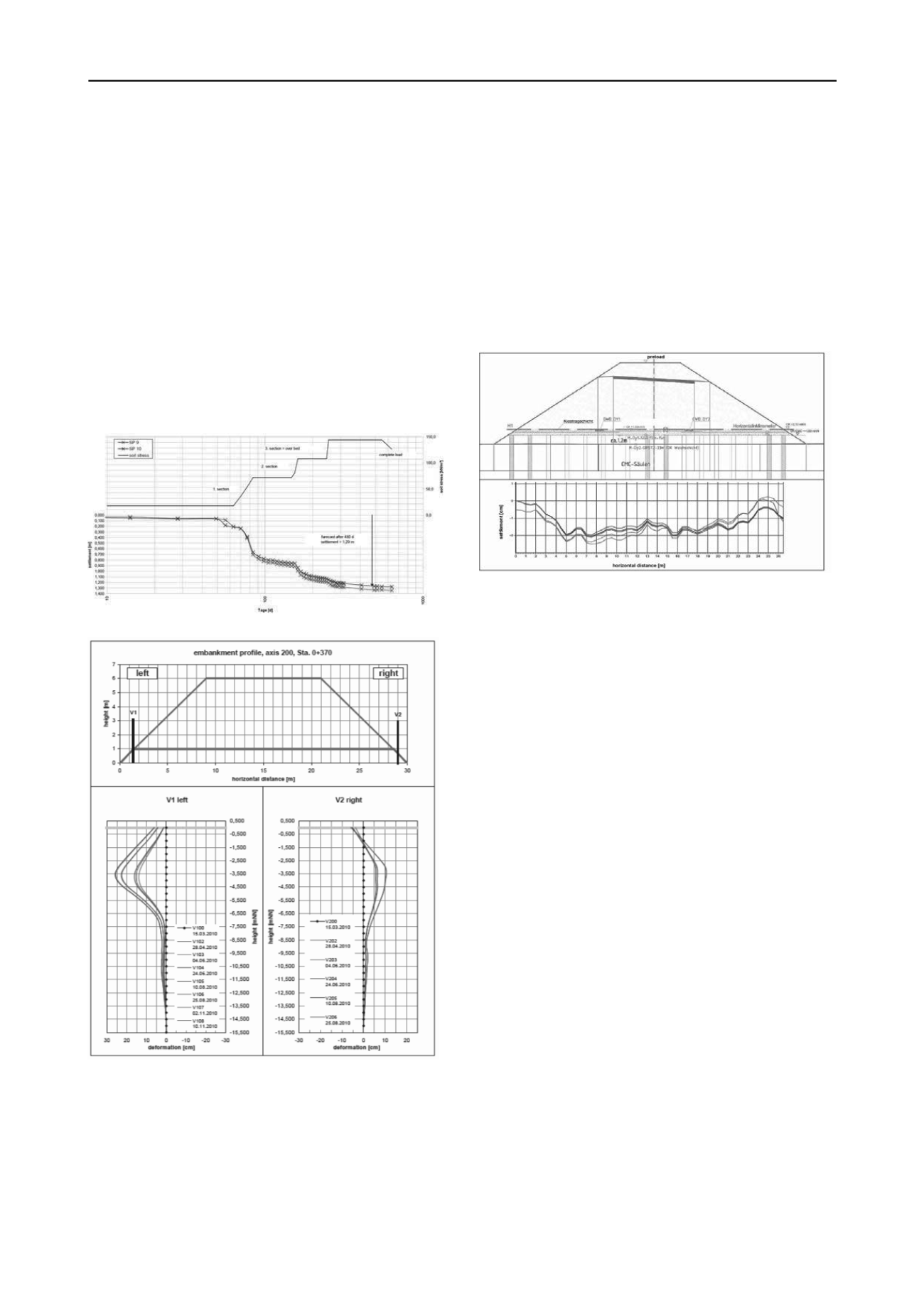

Several measurement systems were installed between the CMC

and the reinforced earth in the load transfer platform. The

instruments show an almost perfect full stress concentration of

the load on the CMC and less than one centimetre of horizontal

deformation. Figure 10 shows the cross section and the 5

vertical deformation measurements over a period of 2 years.

The horizontal inclinometer was laid across six marked CMC-

columns (figure 1 and figure 9). A settlement of one centimetre

of the top of the CMCs and two centimetres in-between CMC in

the reinforced earth steel construction were measured. There

was a good agreement between the calculated values of the

settlement and the results of the monitoring.

F

igure 10. horizontal inclinometer results with arround 1 cm of CMC

settlements and 2 cm of reinforced earth settlements

5 MONITORING RESULTS

5.1

Wick drains

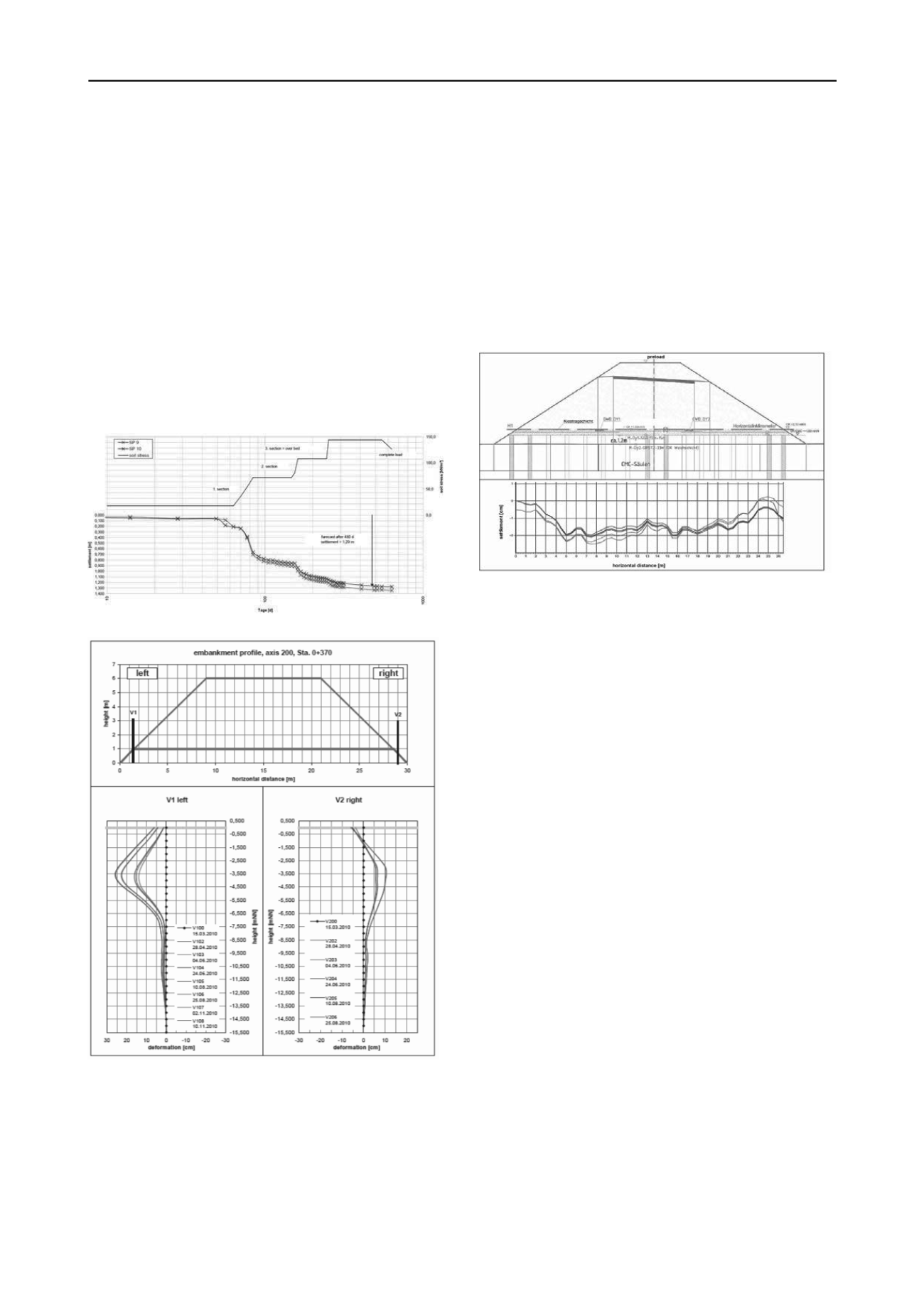

Figure 8. measurement at the settlement plates SP 9 und SP10.

6 SUMMARY AND CONCLUSIONS

F

igure 9. vertical inclinometer results at the 7 m high damm with drains

and 600 kN/m vowen geotextile

Soft and fat clay were found at the B5 / B202 road crossing.

Additional soil investigations and laboratory tests were

performed to be able to complete a proper design, regarding

stability and consolidation time.

Oedometer consolidation tests allowed to precisely predict the

movements during the consolidation processes that were

accelerated by the use of vertical drains at different spacings.

Large deformations of up to 1.5 m of settlements and 27 cm of

horizontal displacement were experience and closely match the

calculations and show that it was the right decision not to place

the highest embankment directly on the softest soil beside the

bridge over the running traffic on the highway B5.

Vibration free CMC in combination with reinforced earth

allowed to construct this high embankment with less than two

centimetre differential settlements to the piled bridge.

With a careful planning of the work within the overall

construction schedule, detailed design combined with an

extensive monitoring program, economic soil improvement

techniques can be combined with deep foundations in one

project even on very soft soil can be treated successfully.

7 REFERENCES

DIN Deutsches Institut für Normung, 2002, DIN 4094-4: Subsoil –

field testing – part 4 : Field vane test.

DIN Deutsches Institut für Normung, 2001, DIN EN 12699: Execution

of special geotechnical work - Displacement piles; German version

J-L Chaumeny, J.F.Kirstein, S. Varaksin, 2008, An experience of

consolidation of extremly soft mud for one of Europe’s largest

projects “The AIRBUS A-380” factory in Hamburg, Glasgow.

The measured settlements during the consolidation process in

figure 8 follow very closely the predictions shown in figure 7.

An additional strong geotextile layer of 600 kN/m tensile

strength between the embankment and the vertical drains had

27 cm of deformation measured with vertical inclinometers.