2522

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 LABORATORY TEST RESULTS

2.1 Parameters of deep-mixing technologies

The quality of the mixed depends on the applied binder type and

quantity as well as the ratio of water to binder in the mixture.

These quantites can be expressed by volume or weight. It is

essential that the water content of the original soil is considered

when calculating the water content of the slurry.

The binder quantity is described with the cement factor (

and the in-place cement factor (

inpl

):

−

=

m

cement

/

V

soil

= binder weight / soil volume [kg/m

3

],

−

inpl

=

m

cement

/

V

mix

= binder weight

/ mixture volume [kg/m

3

].

The water content of the soil is described with

−

w

T

/

c

=

m

w,mix

/

m

cement

= the total water-cement ratio [-].

The quality of the mixture is generally described with two

parameters:

−

q

u

= the unconfined compressive strength [MPa],

−

E

= the Young’s modulus [MPa]).

These mechanical properties are generally measured at 7, 14,

28, 42 and 90 days after mixing, because the stregthening of the

improved soft fine grained soils is a long process, but the qua-

lifying parameter is generally the 28 day unconfined com-

pression strength [Filz et. al., 2003].

2.2 Properties of the chalky silt soil before treatment

Based on the laboratory tests, the main parameters of the

original chalky silt are listed in Table 1.

The soil changes its color if its water content changes: the

in-situ moist soil is pale yellow, while it turns light grey when

drying. It has high lime content; the texture has small roots and

organic threads, and high sensitivity. Based on laboratory tests,

it is classified as highly plastic silt (MH).

Table 1. Soil properties of the chalky silt soil in „Sárrét”

2.3 Data of chalky silt mixtures

In the testing program the use of both deep-mixing

technologies was investigated. Thirteen different mixtures were

prepared by varying

and

w

T

/

c

parameters (Table 2).

Mixtures P1-P3 were made with low water contents and with

slightly-varying cement contents. Mixtures 1-5 were prepared

with lower water contents but highly varying cement contents.

The mixtures 6-10 were made

with a little bit greater water

contents and with cement contents varied in the similar range.

Since the water content of the original soil was high the

addition of water was less significant in comparison to cement.

The cement content dominated the behavior of the mixture.

2.4 Evaluation of stabilized soil parameters

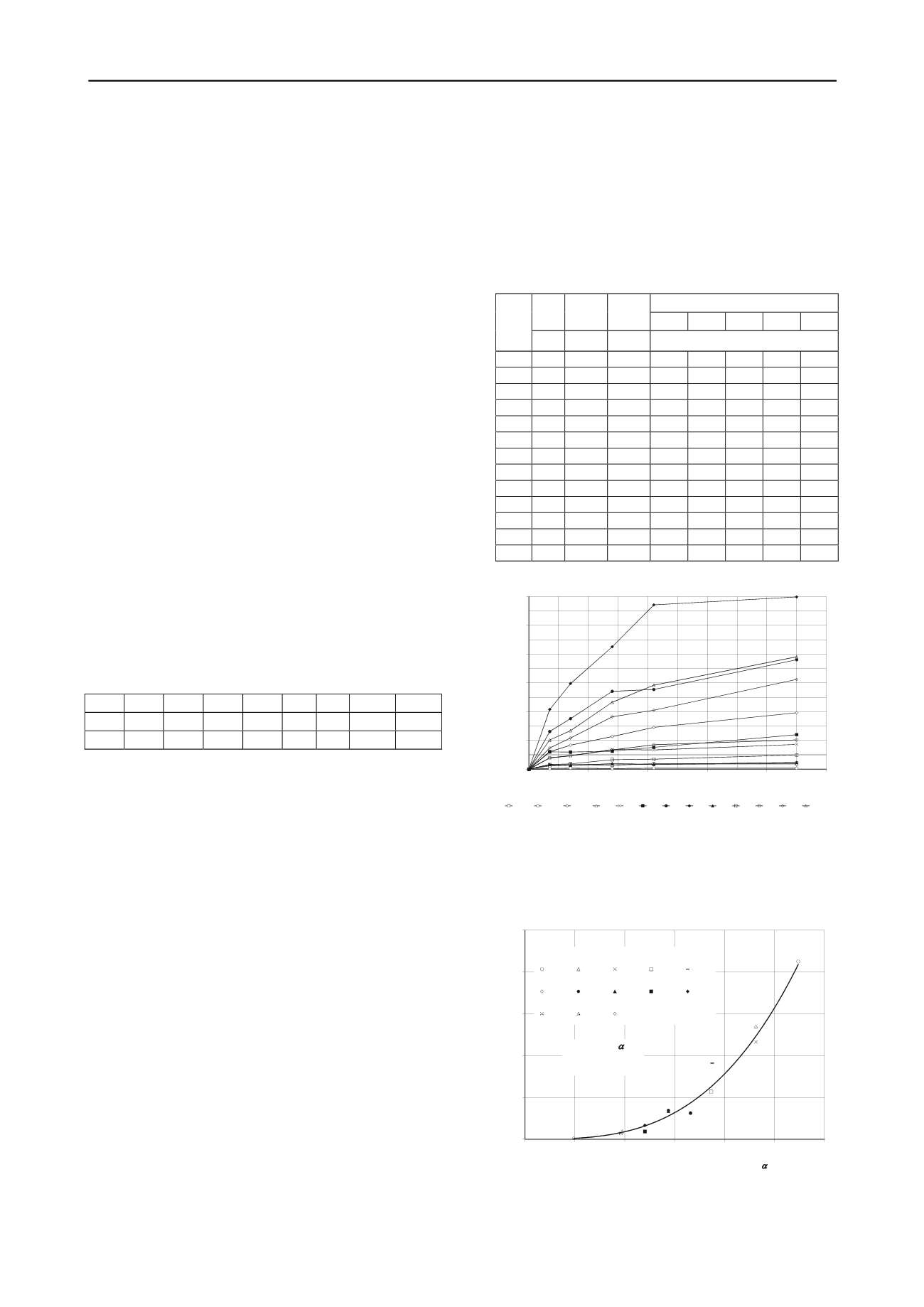

In Figure 3, the increase of unconfined compressive strength

with time is shown. As expected, the strength increases with

time, but the hardening/strengthening rate is different from that

of the concrete. The strength is less than 2.0 MPa for cement

content of 50-300 kg/m

3

. Generally, 0.5-2.0 MPa 28-day

unconfined compressive strength is required for column-type

deep-mixing, and somewhat lower strength for mass

stabilization (Moseley and Kirsch, 2004). The data presented in

figure three indicate that:

− 4 tested mixtures (P2, 1, 6 and 7) which have a cement con-

tent of 125 kg/m

3

or less did not reach 200 kPa unconfined

compressive strength, but 3 of them would be acceptable for

a mass stabilization, only P2 with a cement content of 50

kg/m

3

should be considered as too weak,

− the 28-day unconfined compressive strength of mixtures 2, 3

and 8 (cement content = 150-175 kg/m

3

) was about 330 kPa,

and for 90 days it increased to 500 kPa (50 %). These

mixtures could be accepted for mass stabilization,

− the 28-day unconfined compressive strength of the rest of the

samples with cement contents of 200-300 kg/m

3

were 500-

2000 kPa with a 90-day to 1000-3000 kPa (50-100 %).

These would be acceptable for column-type deep-mixing.

Table 2. Parameters of the mixtures

0

500

1000

1500

2000

2500

3000

0

20

40

60

80

unconfined compressive strength

q

u

[kPa]

hardening time

t

[days]

100

P1 P2 P3 1 2 3 4 5 6 7 8 9 10

Figure 3. Measured hardening/strengthening of chalky silt mixtures

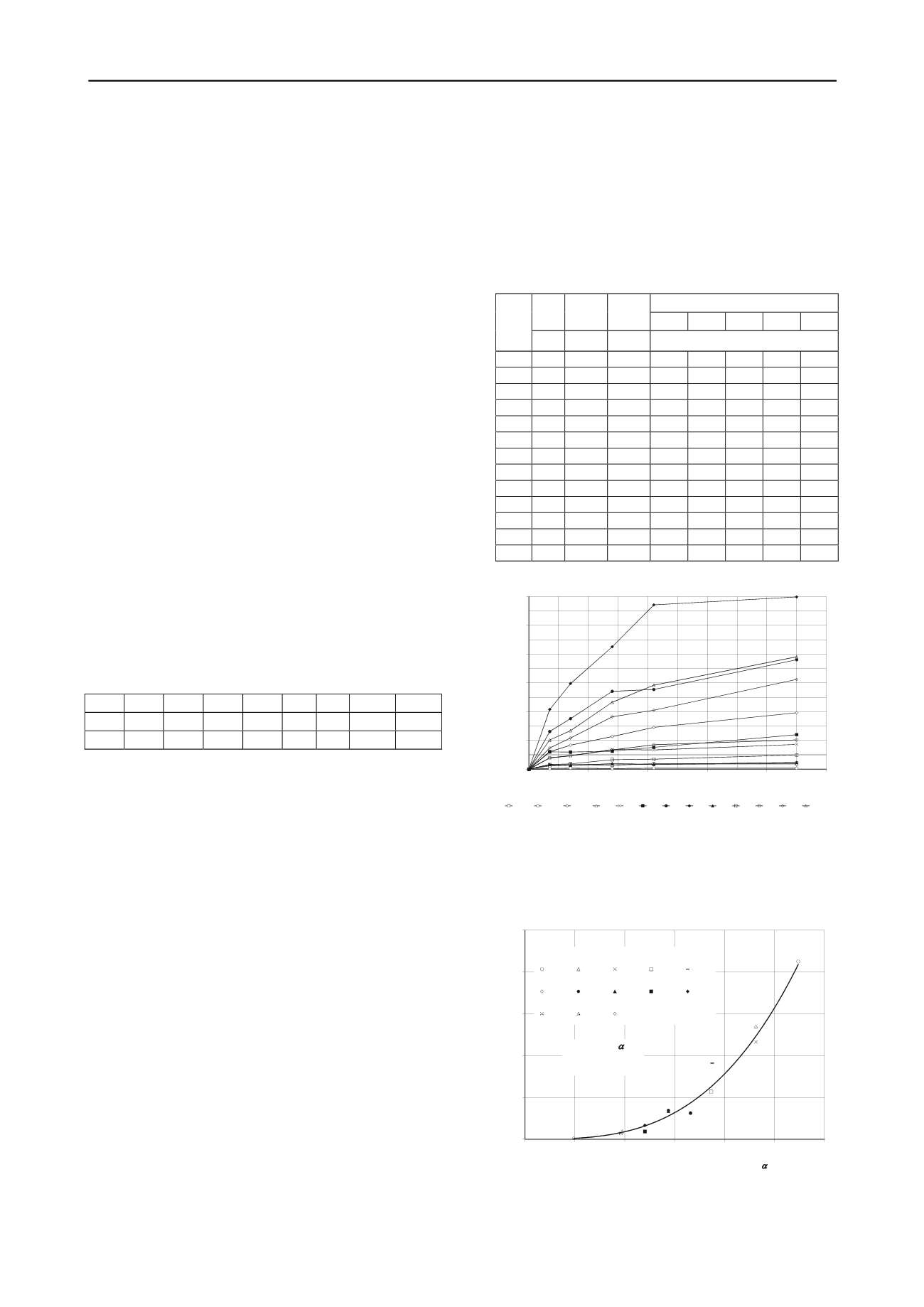

Figure 4 shows the relationship between the 28-day

unconfined compressive strength (

q

u

) and in-place cement

factor (

inpl

). The exponential trendline fits the points well with

R

2

=0.97. The chalky silt responded well to cement addition.

q

u

= 4.8

·

10

-5

·

inpl

3.1

R

²

= 0.97

0

500

1000

1500

2000

2500

0

50

100

150

200

250

300

28 days unconfined compressive strength

q

u

[kPa]

cement factor in-place

inpl

[kg/m

3

]

2,22 2,67 2,74 3,37 3,43

3,81 4,43 4,54 5,33 5,48

6,75 6,81 13,47

w

T

/

c

total water-cement ratio

Figure 4. Measured relationship between

q

u

–

inpl

Figure 5 shows how the 28-day unconfined strength depends

on total water-cement ratio. Samples with high water content

w

L

w

P

I

P

w

e

E

s

E

s,ur

c

*

%

%

%

%

-

MPa MPa

-

-

72.1 54.4 17.7 71.1 2.08 2.1 15 0.0015 0.038

q

u

kPa

w

T

/ c

inpl

7

14

28

42

90

mix-

ture

-

kg/m

3

kg/m

3

day

P1

6.8

102

96

70

80

70

93

104

P2 13.5 51

49

12

17

11

18

17

P3

3.4

204

187

303

418

567

727

980

1

5.3

127

120

58

69

92

88

93

2

4.4

153

144

196

235

343

334

430

3

3.8

178

166

301

297

312

380

598

4

2.7

254

231

655

878 1351 1384 1900

5

2.2

305

274 1037 1487 2125 2853 2991

6

6.8

108

97

81

71

94

82

117

7

5.5

134

120

81

92

165

174

246

8

4.5

162

144

196

231

334

424

508

9

3.4

214

188

370

542

910 1024 1559

10

2.7

268

231

508

670 1162 1458 1952