2523

Technical Committee 211 /

Comité technique 211

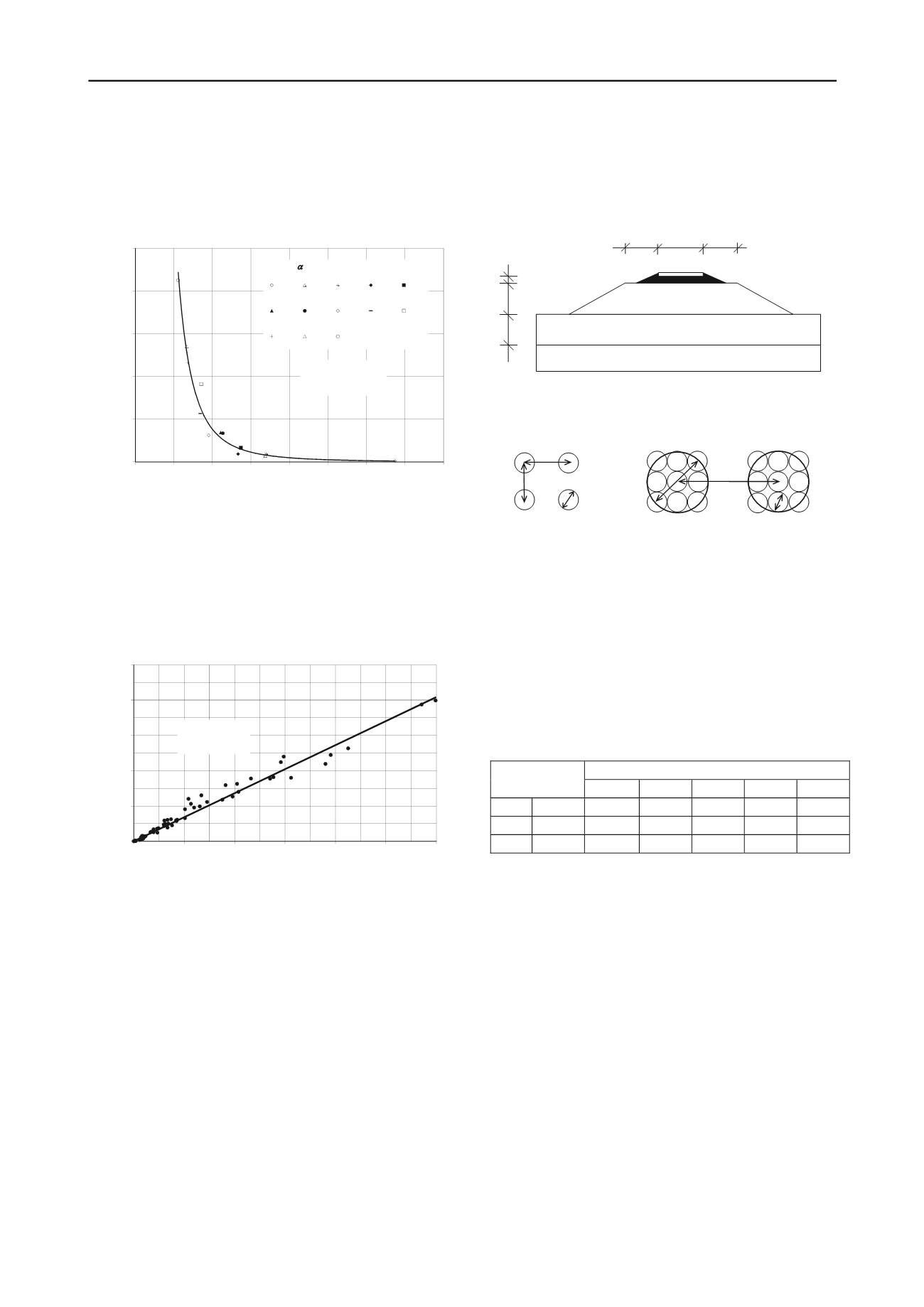

show very low strength, and improvement of soil with

w

T

/

c

> 8

is not possible. When

w

T

/

c

< 4 the strength increased rapidly

with decreasing water-cement ratio, but this also means the soil

is very sensitive to changes in its properties. Since the total

water-cement ratio hardly changes, it is clear that the role of

cement factor is significant.

q

u

= 24000/(

w

T

/

c

)

3.0

R

²

= 0.97

0

500

1000

1500

2000

2500

0

2

4

6

8

10

12

14

16

28 days unconfined compressive strength

q

u

[kPa]

total water-cement ratio

w

T

/

c

[-]

49 96 97 120 120

144 144 166 187 188

231 231 274

inpl

cement factor in-place

Figure 5. Measured relationship between

q

u

–

w

T

/

c

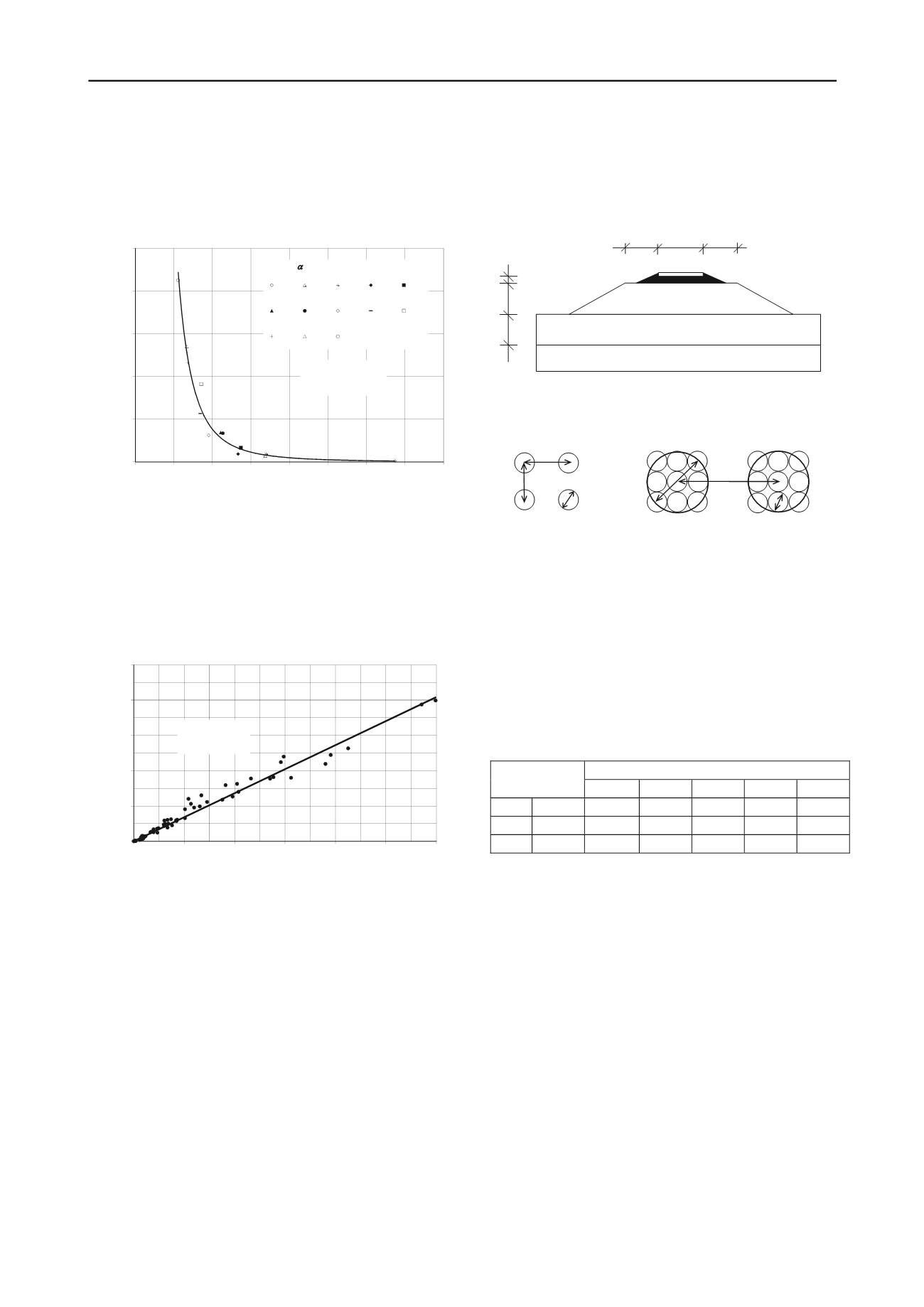

Figure 6 shows the relationship between the unconfined

strength and the Young’s modulus. It can be seen that the trend-

line fits very well. In this respect, the chalky silt of „Sárrét”

behaves as expected: the modulus is proportional to unconfined

strength. The equation from the figure can be simplified to

E

u

= 70·

q

u

(1)

where the units are both in kPa.

E

u

= 0.068 ·

q

u

R

2

= 0,97

0

50

100

150

200

250

0

500

1000

1500

2000

2500

3000

Young modulus

E

u

[MPa]

unconfined compressive strength

q

u

[kPa]

Figure 6. Measured relationship between

q

u

–

E

3 MODELING OF DEEP-MIXING TECHNOLOGIES

3.1 Site evaluation

The second part of our research program was to apply a

calculation method and give some guidelines for design. Both

technologies (column-type and mass stabilization) were studied

for expected design conditions at the Sárrét site. Variation in

soil layering, soil strength and compression parameters, and

embankment height will dictate the choice of technology. The

PLAXIS 3D program was used to assess the effect of

stabilization on stability and settlement.

The geometry of the embankment and the parameters of the

untreated soil are shown in figure 7. Groundwater level was

assumed to be even with the ground surface. Sandy-gravel,

suitable for structural fill, was used for embankment material. A

3-m wide, 52.5 kPa distributed load was placed on top of the

ballast during the stability analysis.

Column diameters were 60 cm, with a 5.0-m uniform length

extending into the gravel layer. The columns were placed in

2.0×2.0-m and 3.0×3.0-m square grids (Figure 8). In order to

model partial mass stabilization, 1.8-m diameter equivalent

columns were placed in 2.4×2.4-m, 3.6×3.6-m and 5.4×5.4-m

square grids (Figure 9.). Total mass stabilization has been

analyzed by modeling the treated soil as a homogeneous

composite of mixed and in-situ soils with averaged strength

properties.

railtrack

embankment

= 20 kN/m

3

1:1.5

E

= 50 MN/m

2

= 40°

= 10°

gravel

E

= 25 kN/m

2

= 36°

= 6°

= 22 kN/m

3

soft soil

E

s

= 2000 kN/m

2

c

ref

= 10 kN/m

2

unsat

=15 kN/m

3

3.0

3.0

3.0

0.6

3.4

5.0

Figure 7. The model geometry and soil properties

The unconfined compressive strength of the 5 mixtures was

used for modeling as base parameters (Table 2). Strength

assigned to the column material in the analysis was assumed to

be half of the unconfined compressive strength measured in the

laboratory. In PLAXIS, this strength is represented by the

cohesion (c

ref

). Based on laboratory tests, Young’s modulus for

the columns was 70 times the unconfined compressive strength.

The value of Poisson’s ratio was

= 0.2 .

Table 2. Mechanical parameters of the mixtures

The analysis modeled the construction and load stages in

five steps:

− placement of deep-mixing soil material,

− construction of initial 2-m high embankment in 30 days,

− construction of final embankment height in 30 days,

− final state (consolidation up to 5 kPa pore pressure).

− stability analysis considering traffic load.

3.2 Analysis of settlement reduction

The results were evaluated by plotting the calculated settlements

versus the unconfined strength of improved soil elements

(Figure 10.). The following conclusions can be drawn:

− with increasing strength all technologies reduce settlement,

but the effectiveness depends significantly on column

diameter and spacing,

− there is a relation between column spacing and

q

u

. If

q

u

is too

small, the column spacing is no longer effective, no matter

how close. At a higher

q

u,

the column spacing scheme is

efficient,

− for partial and total mass stabilization settlements reduce

rapidly as

q

u,

increases, up to 0.4 MPa. Beyond this value,

the improvement is much less significant,

column diameter

d

= 0.6 m

column distance

L

= 2.0 and 3.0 m

distance of equivalent columns

L

= 2.4; 3.6 and 5.4 m

diameter of single

column

d

= 0.6 m

diameter of equivalent

column

d

= 1.8 m

Figure 8.

Column-type deep-mixing

Figure 9.

Partial mass stabilization

mixture

Mohr-

Coulomb

1.

2.

3.

4.

5.

E

ref

kN/m

2

7000

1500

20000

40000

70000

q

u

kN/m

2

100

200

300

600

1000

c

ref

kN/m

2

50

100

150

300

500