2567

Technical Committee 211 /

Comité technique 211

table iii. summary of mass of calcium carbonate

soil column

mass of caco

3

(%)

1 (top)

0.082

1 (bottom)

0.081

2 (top)

0.102

2 (bottom)

0.103

3 (top)

0.070

3 (bottom)

0.068

4 (top)

0.070

4 (bottom)

0.068

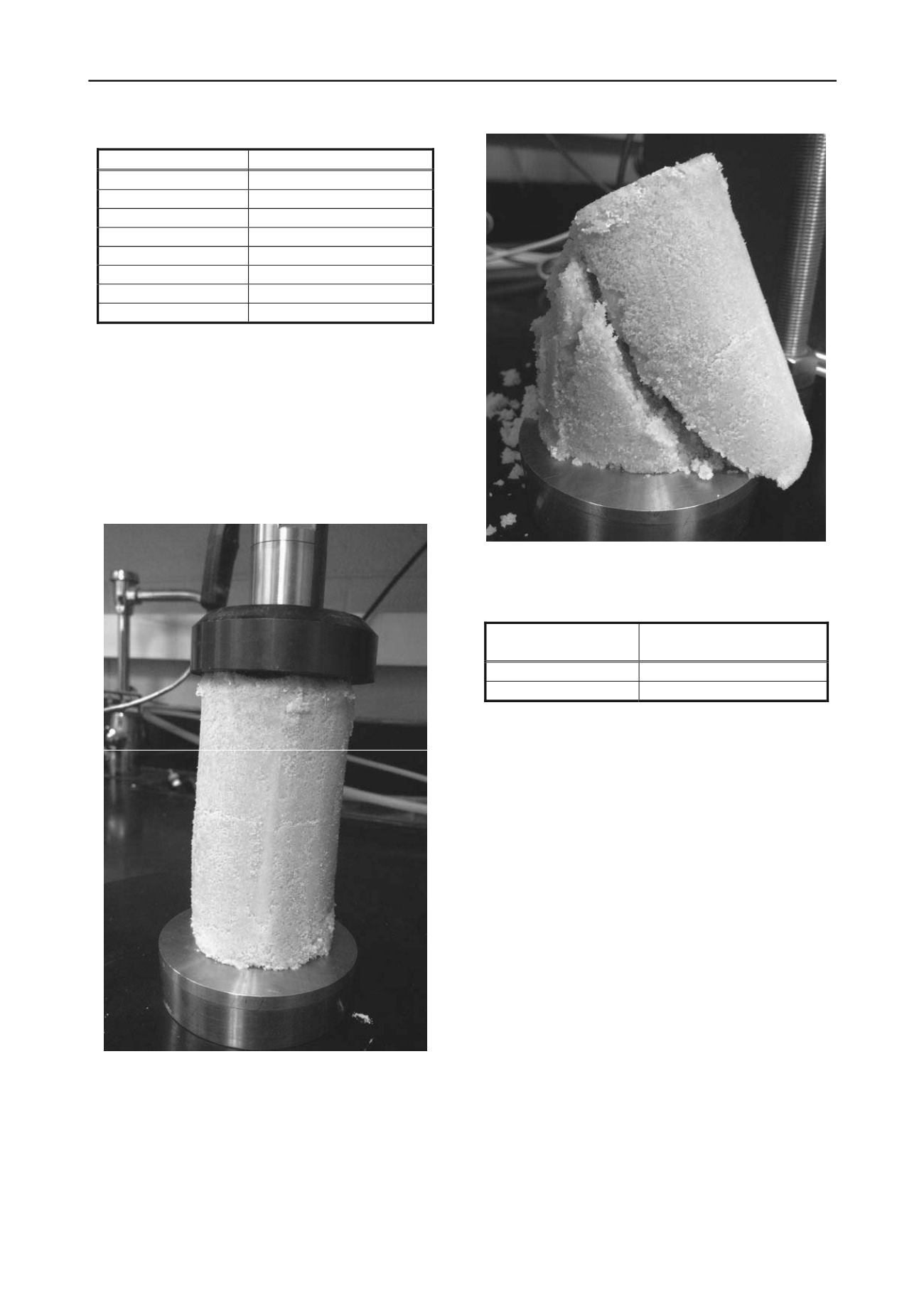

3.2 Cemented Sand Compressive Strength

Unconfined compression tests were performed on the

cemented soil columns (figure 4 and figure 5). as mentioned,

the mass of precipitated calcium carbonate is relatively small

compared to published results from other micp treatment

studies; however even at low mass of calcium carbonate levels,

unconfined compression tests were able to be performed on the

cemented sand columns. a summary of the compression test

results are listed in table iV.

figure 4. cemented soil column mid-test

during the unconfined compression test.

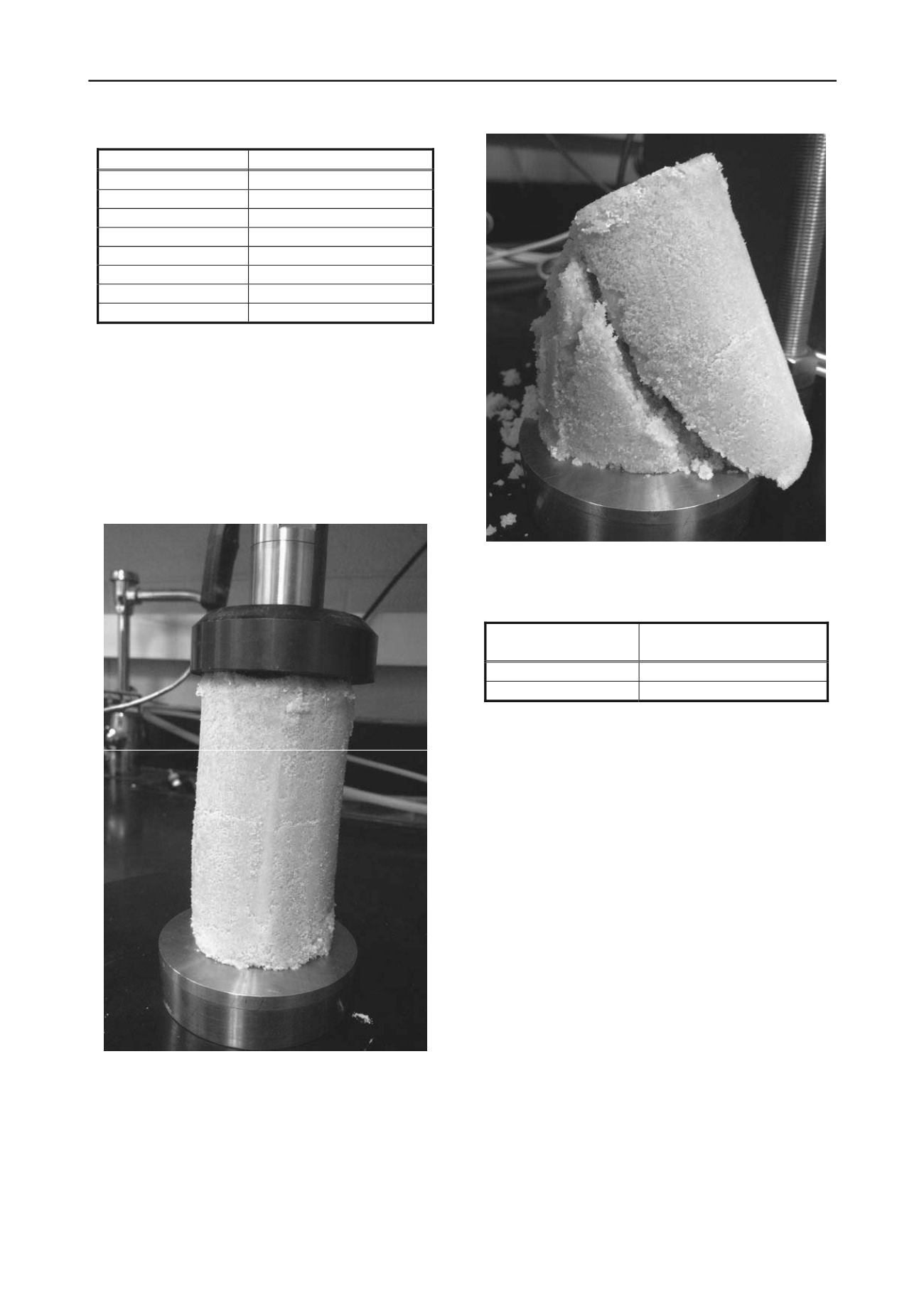

figure 5. failed cemented soil column at the

end of the unconfined compression test.

table iV. summary of compressive strength

soil column

Unconfined compressive

strength (kpa)

1

5.2

4

5.4

as indicated in table iV, unconfined compression tests were

performed on only two of the four columns. two of the soil

columns were not able to be tested because they were

disturbed during extraction from the soil column walls. the

cemented soils were especially vulnerable because of the low

levels of cementation. to rectify the tendency for disturbance,

the soil in the remaining columns was extracted from the soil

column walls by creating vertical slices through the acrylic

walls and allowing the soil to be removed through the sliced

opening.

the unconfined compressive strength of the cemented sand

columns was about 5 kpa. other studies found that micp

treated ottawa 50-70 sand could get compressive strengths of

about 170 to 350 kpa at higher levels of cementation (faison

and mahin, 2012).

the angle of the failure plane in soil columns 1 and 4 was

about 63 degrees from the horizontal. this failure plan angle

is representative of soil with a friction angle of 36 degrees.

Untreated ottawa 50-70 sand has a friction angle of about 33

degrees (montoya, 2012). Based on previous work, micp

treated sand with a friction angle of 36 degrees is typical of

sand treated to a shear wave velocity of 400 m/s (montoya,

2012). an approximate shear wave velocity of 400 m/s

corresponds to the strength data, indicating the cemented soil

columns represent lightly cemented sand.

for use as a treatment process for costal sand deposits, an

appropriate level of micp cementation should be used. a high

enough level of cementation should be used to resist induced

shear loads from waves and storm surges, and a low enough

level of cementation so that native wildlife, such as birds,

burrowing animals, and dune grass, can still interact with the

coastal deposits. further work will include upscaling the