2574

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Settlement

gauge (G1)

60 kPa

10 m

1 m

20 m

PVD

Intact zone

Smearzone

0 m

Clayey

silt/Silty

clay

(CL/ML)

Silty

sand

7m

10m

1m

Sand bags

9m

3.0m

C

L

G1

PVDs

Surcharge Material

γ

t

=20 kN/m

3

LL=45

PI=18

Gs=2.74

G2

4m

0

1

2

3

4

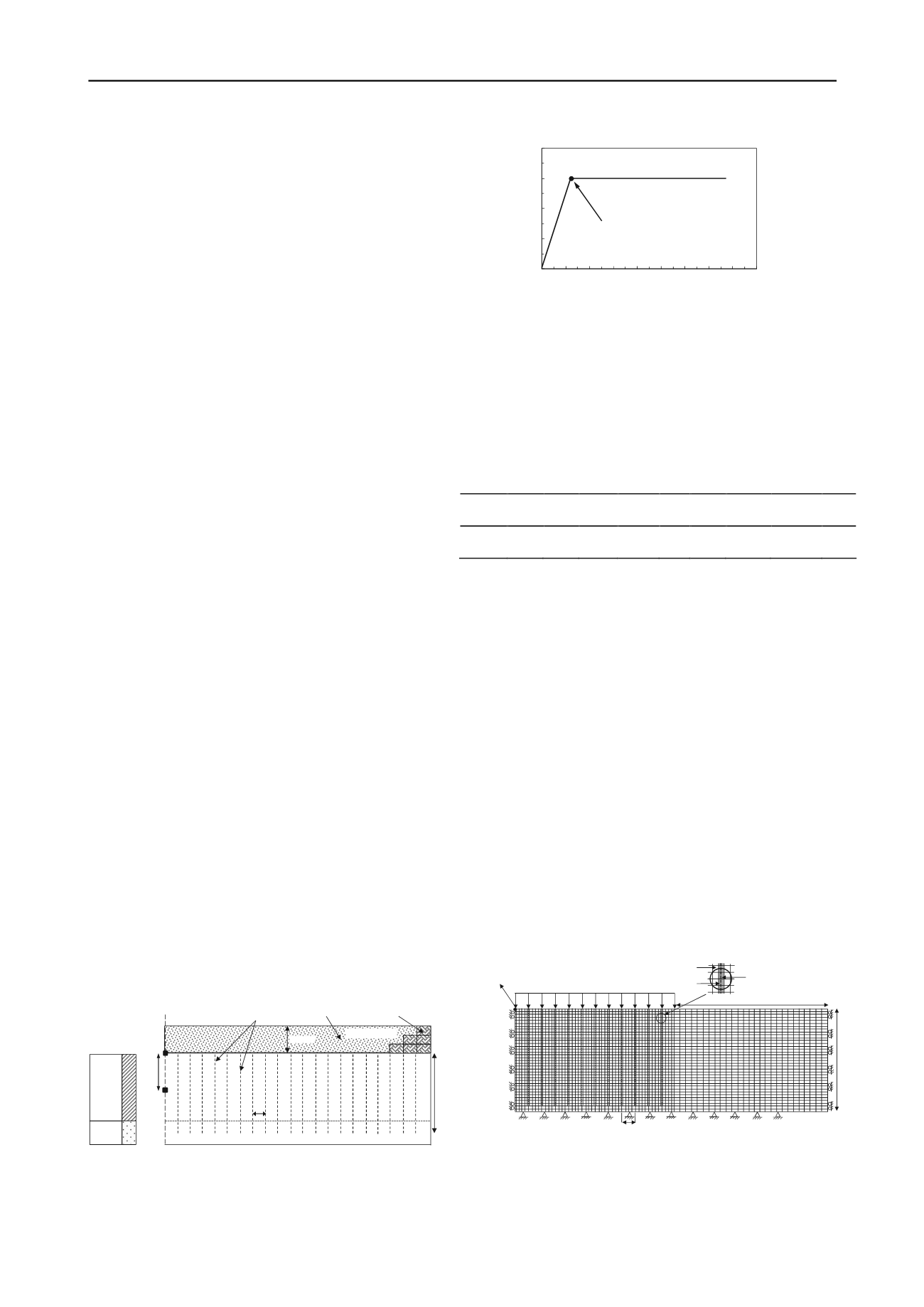

0 10 20 30 40 50 60 70 80 90

EmbankmentHeight (m)

Time (days)

Commencementof recording

settlement plate readings

inaccurate predictions of the ground behaviour. This can lead to

early removal of surcharge in construction process resulting in

excessive post construction settlement. Therefore, it is essential

to study the influence of the uncertainties in the smear zone size

and its permeability on the preloading design to improve the

performance of soft deposits. Thus, a numerical code using

FLAC 2D has been developed in this study to investigate the

uncertainties of PVD smear zone characteristics on the

preloading design which can be used to back calculate smear

zone characteristics for actual preloading projects.

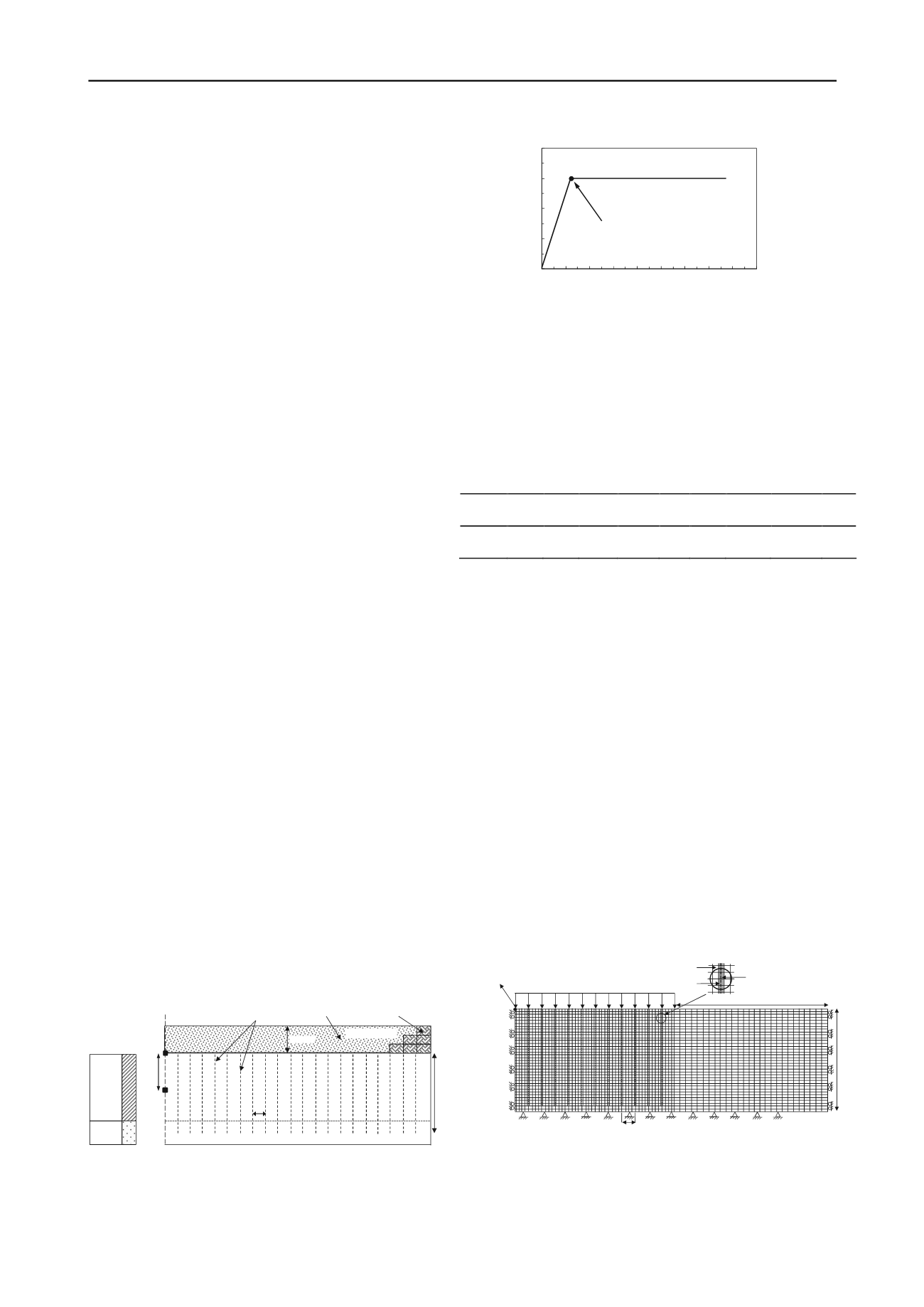

2 NUMERICAL MODELLING

In the present study, FLAC 2D v6.0 has been employed to

model the PVD assisted preloading process focusing on smear

zone uncertainties. Required new subroutines have been written

using the built-in programming language FISH (FLACish) to

tailor analyses to suit specific needs for the parametric study,

giving the following unique advantages to the developed code

for this study; (i) automatic mesh generation process by entering

the required parameters to modify the grid pattern inside and

outside the smear zone; (ii) ability to change different

parameters such as the model dimensions, vertical drain

properties, subsoil profile, smear zone characteristics and

preloading conditions; (iii) the option to define the exact

location of desired points to generate and plot any future history

graphs; and (iv) automatic solving process based on the

modified input data. Chittagong Sea Port in Bangladesh with

3.0 m high embankment on 9 m deep soft clay, has been

selected for the numerical simulations and verification of the

developed code and subroutines.

2.1.

Case Study: Chittagong Sea Port in Bangladesh

According to Dhar et al. (2011), a container yard has been

constructed at Chittagong Port, the largest sea port in

Bangladesh, for handling loaded containers. The site is located

on the bank of Karnafully river beside the Bay of Bengal in the

Indian Ocean. The yard covers an area of 60,700 m

2

and was

designed to support a container load producing a contact

pressure of approximately 56 kPa. Geotechnical investigations

revealed the presence of a soft to very soft clayey silt/silty clay

deposit with a thickness of approximately 7 m (Figure 3).

Preloading with prefabricated vertical drains was adopted to

preconsolidate the compressible soft deposits, which was

followed by the field monitoring. Vertical drains were installed

down to the depth of approximately 9 m below the ground level

in square patter to cover the full depth of the soft clay. A

surcharge load consisting of 3.0 m high fill of sand was placed

for preloading. Surcharge material was placed in two layers of

approximately equal thickness. The sides of the surcharge load

were kept vertical along the boundaries of the area using sand

bags and brick stacks. Figure 3 shows a profile detailing the

ground improvement work schematically. In addition, Figure 4

shows the construction history of the embankment.

Figure 3. Cross section of constructed embankment

Figure 4. Construction history (Chittagong Port embankment)

FLAC 2D numerical code incorporating modified Cam-Clay

constitutive soil model has been employed to simulate

Chittagong Port preloading process applying plane strain

conditions. The zero excess pore water pressure has been

considered along the vertical drains and the ground surface

boundary to model the PVD and surface drainage, respectively.

Adopted soil properties in the numerical analysis are

summerised in Table 1.

Table 1. Adopted soil properties (after Dhar et al. 2011)

Layer

Soil

type

M

λ

κ

ν

e

○

γ

s

kN/m

3

k

h

10

-9

m/s

k

h

/

k

v

Clayey

Silt

Soft

soil

0.94 0.13 0.026 0.3 1.28 14.0

2.31 1.5

The equivalent plane-strain permeability (k

hp

) proposed by

Indraratna and Redana (2000) has been used in the numerical

analysis.

(

k

hp

/k

h

)

= 0.67

/ [(ln(

n

)

-0.75

]

(1)

(

k

sp

/k

hp

)

=

β

/ [(

k

hp

/k

h

) [(ln(

n

/

s

)

+

(

k

h

/k

s

) ln(

s

)-

0.75

]-

α]

(2)

α

=

2

(

n

-

s

)

3

/ [3(

n

-

1

)

n

2

]

(3)

β

= [

2

(

s

-

1

) / (

n-1

)

n

2

] * [

n

(

n

-

s

-

1

) +

1

/

3

(

s

2

+

s

+

1

)]

(4)

where,

k

h

and

k

hp

are axisymmetric and plane-strain horizontal

permeability values of intact zone respectively,

k

s

and

k

sp

are

axisymmetric and plane-strain permeability values of smear

zone, respectively,

α

and

β

are geometric coefficients,

n

is the

spacing ratio equal to

B/b

w

where

B

and

b

w

are equivalent plane-

strain radius of the influence zone and radius of the drain

respectively, and

s=r

s

/r

w

. The value of

k

h

needs to be

determined first (laboratory or field), then

k

hp

can be calculated

using Equation (1). When

k

hp

is known,

k

sp

can be obtained

from Equation (2). The discretised plane- strain finite-difference

mesh composed of quadrilateral elements is shown in Figure 5,

where only half of the trial embankment is considered by

exploiting symmetry.

Figure 5. Sample of mesh grid pattern for Chittagong Port embankment

considering the smear

Numerical results are compared with the field measurements in

Figure 6. According to Figure 6, FLAC predictions are in a

good agreement with the field measurements considering

k

h

/k

s

=2 and r

s

/r

m

=3. The primary consolidation settlement is