2570

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Table 1. Bleed capacity values (%) of all cement grouts

W/C

dmax

0.6

0.8

1.0

2.0

3.0

100μm

5-10

17-19

16-39

44-60

60-70

40μm

5-7

11-15

10-26

42-55

56-68

20μm

N/T

N/T

0-4

25-37

43-49

10μm

N/T

N/T

0-2

7-26

38-42

N/T: Not tested

the total amount of cement, 70 % of the water and the

superplasticizer dosage were mixed for 5 min. Then, the rest of

the water was added and mixing continued for another 5 min.

Bleed capacity measurements were conducted for all cement

suspensions used and the results are summarized in Table 1.

According to Standard EN 12715, a suspension is stable

when it has a bleed capacity of not more than 5 % after 120 min

from preparation. It can be observed that a W/C ratio of about

0.6 was required to obtain stable suspension of the coarse

cements (d

max

=100μm and 40μm)

while microfine cement

suspensions were stable for a W/C ratio of 1.0

The soils used were clean, uniform, limestone sands with

angular grains and were grouted at a dense (relative density

approximately 90%) and dry state. Two different sand

gradations were used with grain sizes limited between sieve

sizes (ASTM E11) Nos. 10-14 and 14-25 (d

15

size of 1.5mm

and 0.8mm, respectively) in order to allow grouting by both the

coarse- and fine-grained suspensions. The angle of internal

friction of the sands was 42.2

°

and 42.6

°,

respectively.

Laboratory equipment, similar to the arrangement described

in ASTM D4320-84, was used to produce small-size grouted

sand specimens, with a height of 112mm and a diameter of

50mm, ready for testing (Pantazopoulos et al. 2012). Injection

was stopped when the volume of the injected grout was equal to

two void volumes of the sand in the molds. After 24 h, the

specimens were extracted from the split molds and cured in a

humid room for 28 days before testing.

Grouted specimens were tested in unconfined compression at

a displacement rate equal to 0.1%/min. Hydraulic conductivity

tests were performed according to the procedure described by

Head (1986) for permeability testing in a triaxial cell with two

back-pressure systems. Drained triaxial compression tests were

conducted under confining pressures of 100, 200 and 400kPa

and axial strain rate equal to 0.1%/min, without initial saturation

and consolidation.

The dynamic properties of the grouted sands

were investigated at confining pressures up to 400kPa by

conducting torsional resonant column tests for a shear strain

range, γ, of approximately 5*10

-5

% to 5*10

-2

%. Testing

procedures and interpretation of raw data complied with well

established methods (Pantazopoulos and Atmatzidis 2012). For

comparison, similar tests were conducted on clean sands.

3

COEFFICIENT OF PERMEABILITY

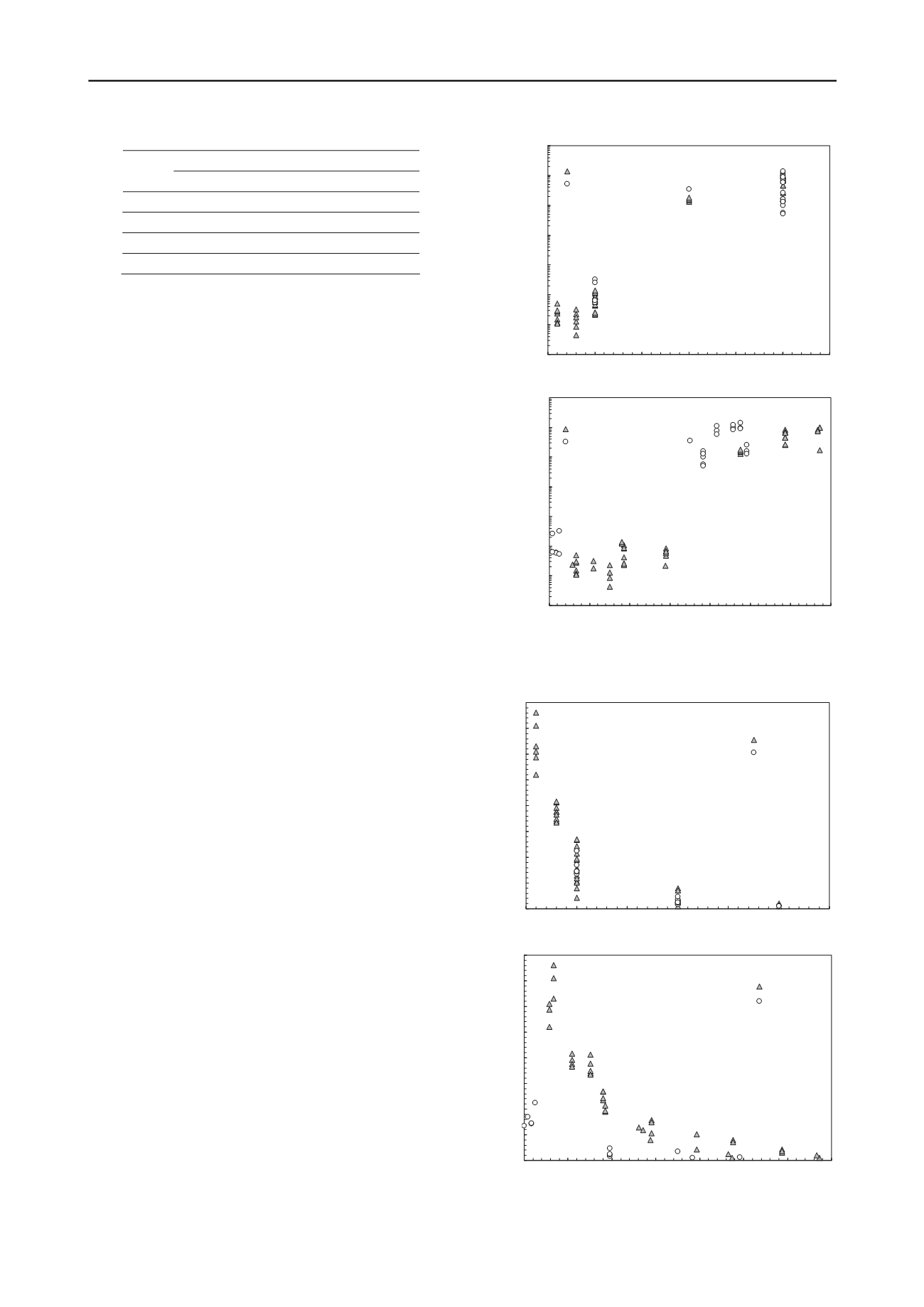

The coefficient of permeability values of all grouted sands

tested are presented in Figure 2 with respect to W/C ratio, bleed

capacity and maximum cement grain size of the suspensions.

The coefficient of permeability decreases considerably (by

about 5 orders of magnitude) as the W/C ratio decreases from 3

to 0.6 and attains a value of about 10

-7

to10

-8

cm/s indicating

practically impermeable materials. The permeability of the

grouted sands appears not to be affected by the cement grain

size. Evaluation of the permeability of the grouted sands in

terms of grout bleed capacity indicates a similar trend as with

the W/C, but allows some observations to be made in terms of

the effect of cement grain size. For cement grouts with d

max

equal to 100μm and 40μm, the coefficient of permeability of the

grouted sands attained values in the range of 10

-7

to 10

-8

cm/s

and 10

-3

to 10

-4

cm/s, for grout bleed capacity ranging from 6%

1.00E-09

1.00E-08

1.00E-07

1.00E-06

1.00E-05

1.00E-04

1.00E-03

1.00E-02

0.5

1

1.5

2

2.5

3

3.5

Water-to-cement ratio, W/C

Coefficient of permeability, k

20

(cm/s)

100μm - 40μm

20μm - 10μm

d

max

1.00E-09

1.00E-08

1.00E-07

1.00E-06

1.00E-05

1.00E-04

1.00E-03

1.00E-02

0

10

20

30

40

50

60

7

Bleed capacity (%)

Coefficient of permeability, k

20

(cm/s)

0

100μm - 40μm

20μm - 10μm

d

max

Figure 2. Effect of grout W/C ratio and bleed capacity on the

permeability of cement grouted sands.

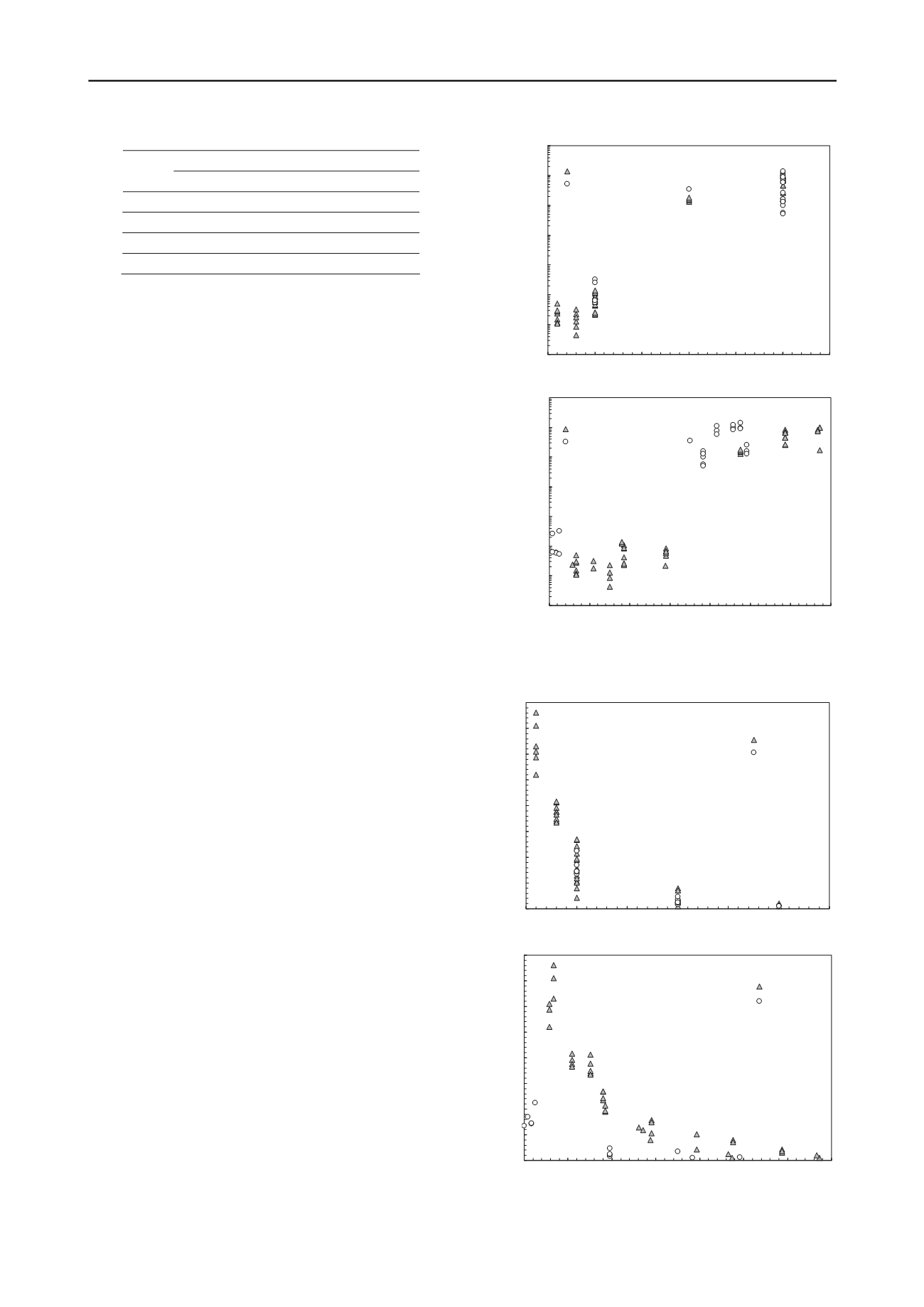

0

5

10

15

20

25

30

35

40

0.5

1

1.5

2

2.5

3

3.5

Water-to-cement ratio, W/C

Unconfined compr. strength, q

u

(MPa)

100μm - 40μm

20μm - 10μm

d

max

0

5

10

15

20

25

30

35

40

0

10

20

30

40

50

60

7

Bleed capacity (%)

Unconfined compr. strength, q

u

(MPa)

0

100μm - 40μm

20μm - 10μm

d

max

Figure 3. Effect of grout W/C ratio and bleed capacity on the

unconfined compression strength of cement grouted sands.