2571

Technical Committee 211 /

Comité technique 211

to 30% and from 48% to 68%, respectively. Sands injected with

microfine cement grouts (d

max

=20μm and 10μm) obtained,

generally, higher coefficients of permeability, by half to one

order of magnitude, compared to sands grouted with the coarser

cement suspensions, for similar bleed capacities. This is

reasonable and can be attributed to the increased amount of

coarse-grained cement needed to obtain the same bleed capacity

with suspensions of microfine cements. It should also be noted

that (a) similar coefficient of permeability values (10

-7

to 10

-8

cm/s) are obtained when injecting with stable or unstable

suspensions for bleed capacity values up to 30% and (b) for

higher bleed capacity values, the coefficient of permeability of

the grouted sand decreases dramatically but remains in the

range of 10

-4

to 10

-3

cm/s.

4

UNCONFINED COMPRESSION STRENGTH

The results presented in Figure 3 indicate that the unconfined

compression strength of the grouted sands increases

significantly with decreasing W/C ratio of the grouts, as verified

by other research efforts (i.e. Dano et al. 2004) and seems not to

affected by cement grain size. However, the effect of cement

grain size can be clearly demonstrated in terms of grout bleed

capacity. The unconfined compression strength of the grouted

sands is very well correlated with grout bleed capacity of both

the coarse-grained cements (d

max

=100 and 40μm) and the

microfine cements (d

max

=20 and 10μm) but, definitely,

microfine cement grouts with the same bleed capacity as cement

grouts yield significantly lower grouted sand strength. As with

permeability, this can be attributed to the increased amount of

coarse-grained cement needed to obtain the same bleed capacity

as microfine cement suspensions.

5

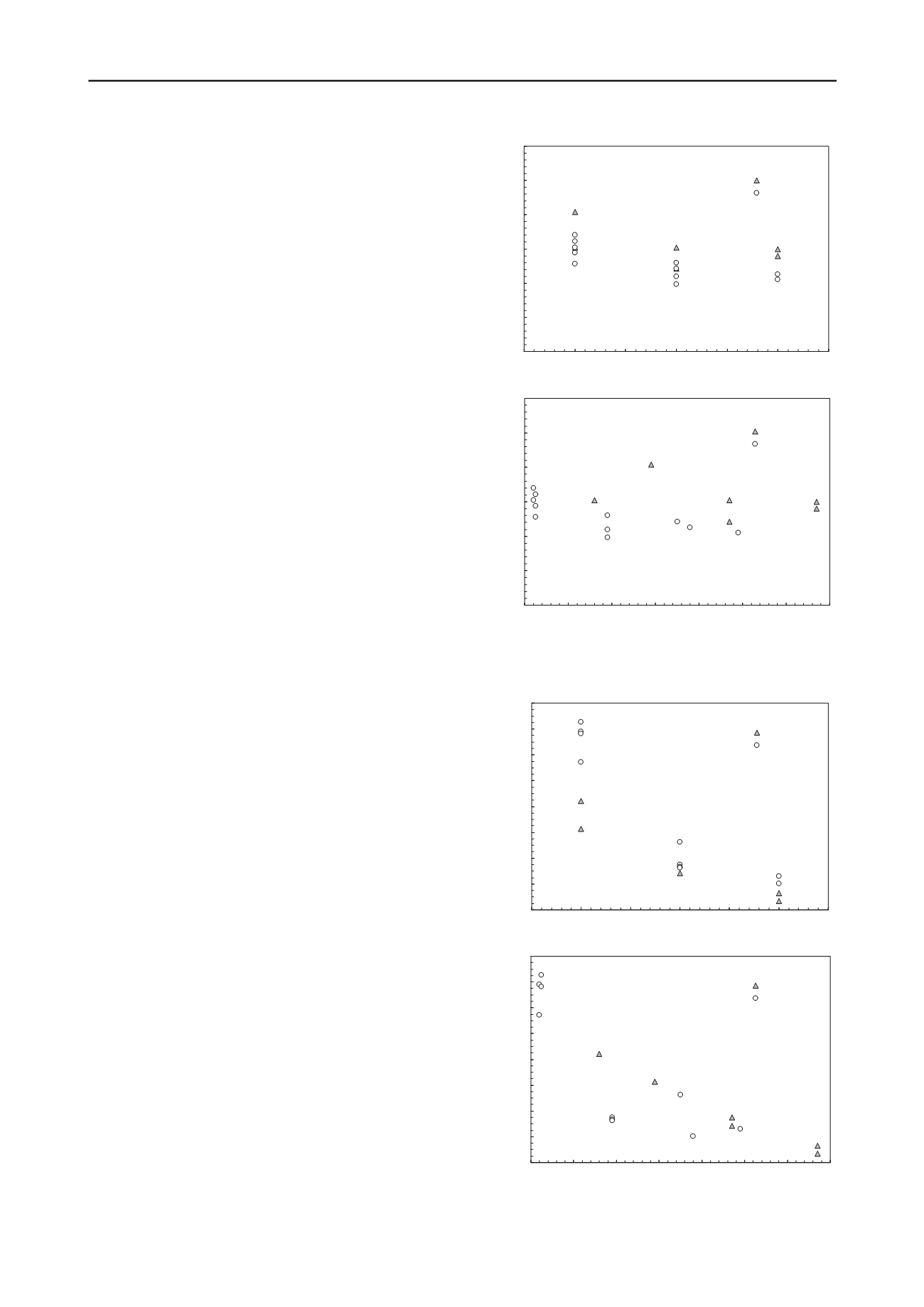

SHEAR STRENGTH

The shear strength of the grouted sand specimens is expressed

in terms of internal friction angle and cohesion, by applying the

Mohr-Coulomb failure criterion. As indicated in Figure 4, the

internal friction angle ranged from 40° to 50° and the effect of

W/C ratio, bleed capacity and cement grain size appear to be

insignificant. In general, the internal friction angle of the

grouted sands was up to 5° higher than the value obtained for

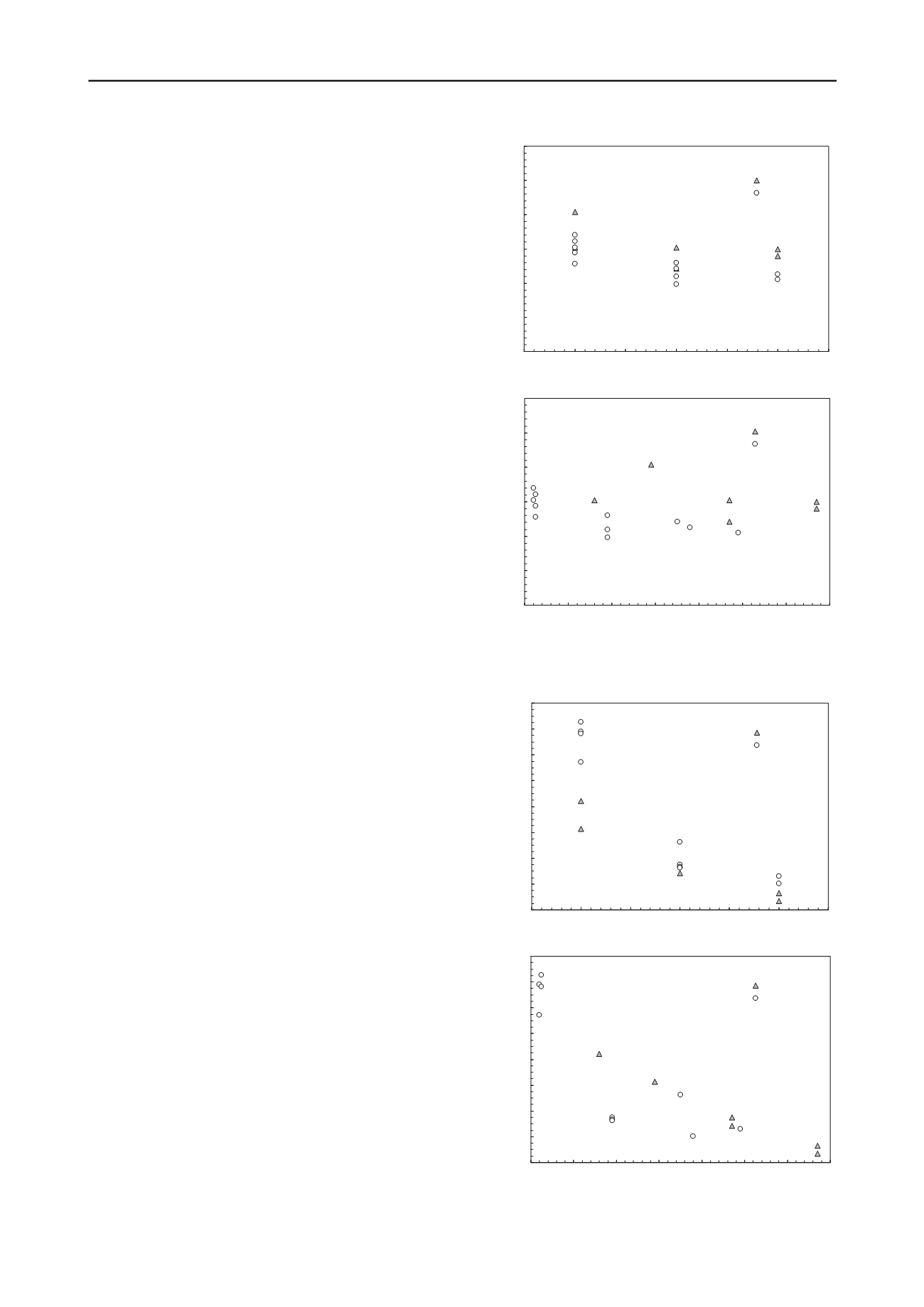

clean sands. The cohesion of the grouted sands is strongly

affected both by the W/C ratio and by the bleed capacity of the

grouts. As shown in Figure 5, the cohesion values of the grouted

sands ranged from 600kPa to 1450kPa, from 300kPa to 500kPa

and from 50kPa to 250kPa, for W/C ratios equal to 1, 2 and 3,

respectively. Furthermore, grouted sands injected with stable

grouts (bleed capacity values less than 5%) obtained the highest

cohesion values ranging from 1200kPa to 1450kPa. Increased

bleed capacity values (unstable suspensions) in the range of

15% to 65%, leads to an almost linear decrease of the cohesion

values from 800kPa to 100kPa. The effect of cement grain size

on grouted sand cohesion, as shown in Figure 5, where the

microfine cements exhibit higher values of cohesion than the

coarse-grained cements, by 40% to 150%, is misleading since

the suspensions used had different bleed capacities for the same

W/C ratio. For example, at W/C ratio equal to 1, the microfine

cement suspensions are stable (bleed capacity < 4%) and fill the

sand voids with cement more completely and uniformily than

the coarse cement suspensions with W/C=1 (bleed capacity

>16%).

6

SHEAR MODULUS

Presented in Figure 6 are typical results obtained for the

shear modulus, G, of grouted sands at a confining pressure

equal to 50kPa and shear strain equal to 10

-5

%. The effect of

confining pressure is not pronounced for the grouted sands

tested (Pantazopoulos and Atmatzidis 2012). As shown in

Figure 6, the shear modulus values decrease, from 4.1GPa to

30

35

40

45

50

55

60

0.5

1

1.5

2

2.5

3

3.5

Water-to-cement ratio, W/C

Internal friction angle, φ (

ο

)

100μm - 40μm

20μm - 10μm

d

max

σ

3

(kPa)

100 - 200 - 400

30

35

40

45

50

55

60

0

10

20

30

40

50

60

7

Bleed capacity (%)

Internal friction angle, φ (

ο

)

0

100μm - 40μm

20μm - 10μm

d

max

σ

3

(kPa)

100 - 200 - 400

Figure 4. Effect of grout W/C ratio and bleed capacity on the internal

friction angle of cement grouted sands.

0

200

400

600

800

1000

1200

1400

1600

0.5

1

1.5

2

2.5

3

3.5

Water-to-cement ratio, W/C

Cohesion, c (kPa)

100μm - 40μm

20μm - 10μm

d

max

σ

3

(kPa)

100 - 200 - 400

0

200

400

600

800

1000

1200

1400

1600

0

10

20

30

40

50

60

Bleed capacity (%)

Cohesion, c (kPa

70

)

100μm - 40μm

20μm - 10μm

d

max

σ

3

(kPa)

100 - 200 - 400

Figure 5. Effect of grout W/C ratio and bleed capacity on the cohesion

of cement grouted sands.