2364

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

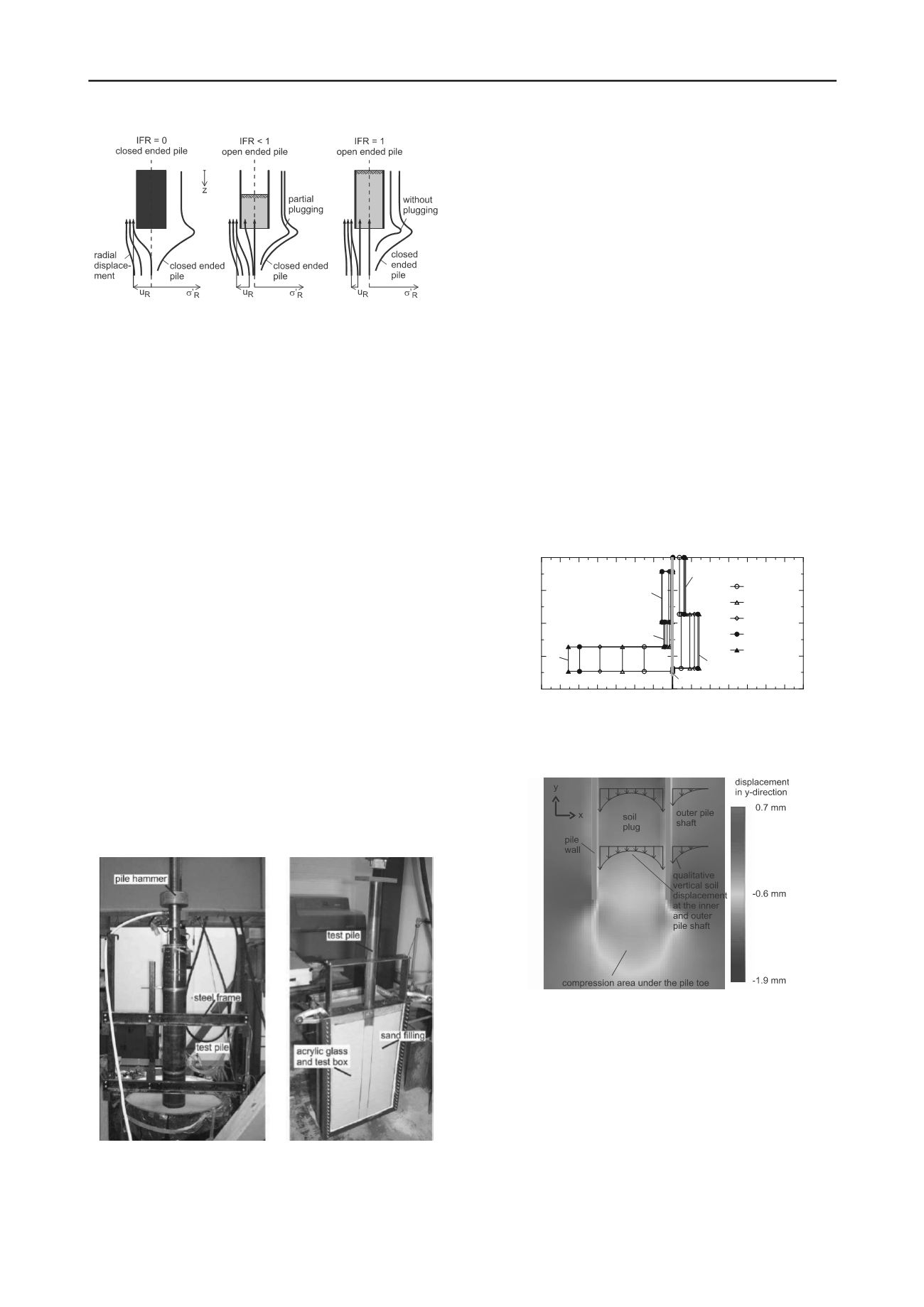

Figure 1. Distribution of the radial displacement u

R

and the radial stress

'

R

on the pile shaft depending on different IFR after White et al. 2005

3 EXPERIMENTAL INVESTIGATIONS

3.1

General

Different experimental investigations were carried out. The next

section gives a short overview of the laboratory test program

before the results are discussed. A detailed description and a

documentation of all test results is given in Lüking 2010.

3.2

Model Tests and Particle Image Velocimetry Tests

In the first test series a test pile of two pipe piles was

constructed. Both piles were only connected at the top. In all the

test pile had the following geometry: outer pile diameter 19 cm

and inner pile diameter 16 cm. The pile embedded depth after

driving the test pile into a sand box was about 140 cm. After

this a static pile test loading was carried out.

This test pile was equipped with different strain gauges.

Based on the measured strain

the inner shaft friction q

is

, the

outer shaft friction q

s

and the pile toe pressure q

b

could be

calculated. By means of a special constructed cone-penetration-

test (lab-CPT) the change in density and the displacement effect

of the pile installation could be examined.

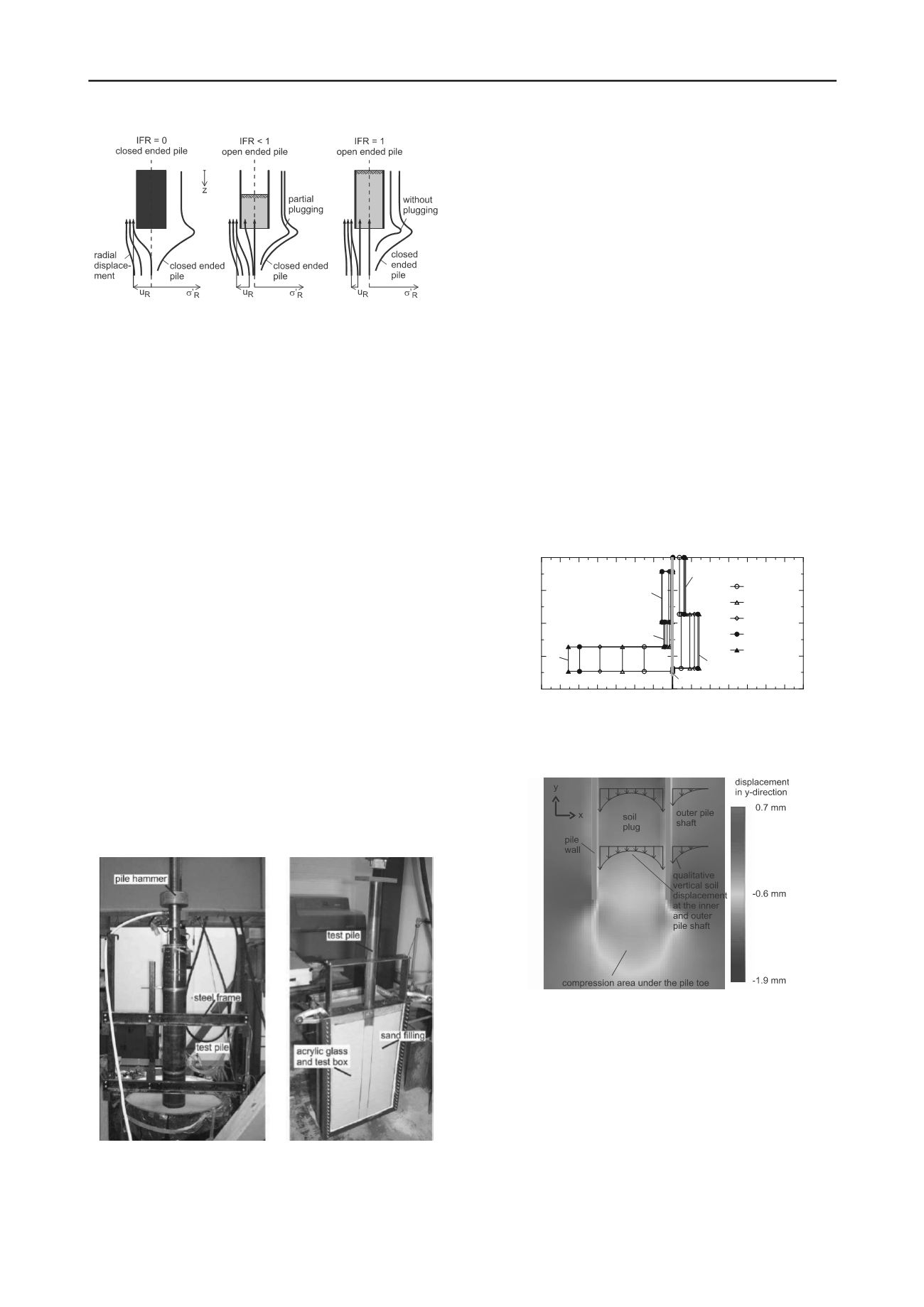

In the second test series Particle Image Velocimetry (PIV)

tests were carried out. The PIV method is a contact free

measurement, in which displacement vectors can be identified.

Basics to this method can be found in Raffel et al. 2007.

The test pile in the second test series had an outer pile

diameter of 60 mm and a wall thickness of 2 mm. It was driven

behind an acrylic glass to an embedded depth of 50 cm. Figure

2 gives a perspective view of both test series which were mainly

carried out in non-cohesive soils.

Figure 2. Perspective view of a) test pile of the first test series and b)

test pile of the second test series (PIV)

3.3

Results of the experimental test series

In general the experience on the pile bearing behaviour

regarding different influence factors could be confirmed. With

an increasing relative density and increasing stress level the pile

bearing capacity is also increasing.

The change in density around the test pile was lower in

dense sands than in loose sands, which could be identified by

different tests with the lab-CPT. The base resistance of the lab-

CPT inside the soil plug was up to 80 MPa. A higher density of

the soil tends to a higher IFR. Nevertheless the IFR does not

converge to a fixed value. It was increasing and also decreasing

during driving which means that the soil inside was plugging

and loosening again. This phenomenon was also identified

during the static pile test loading. However during both test

series the value never reached IFR = 0. The minimum was

IFR = 0.2. This means that only a partially plugged soil could

occur and based on this the concept of a monolithical soil plug

should be analyzed critically.

Figure 3 shows the distribution of the inner and outer shaft

friction at different load levels from the first test series. The

outer shaft friction is increasing with higher pile length as

expected. In contrary the inner shaft friction is very high on a

length which approximate two pile diameters. Above this the

inner shaft friction in section 1 and 2 is very low and it looks

approximately independent of the load level. The increasing of

the inner shaft friction in section 3 is an indication for a (partial)

plugging effect of the soil.

0 50 100 150 200 250 300 350

outer skin friction q

s

[kN/m

2

]

load levels

30.1 kN

60.2 kN

90.2 kN

120.3 kN

135.3 kN

160

120

80

40

0

pile length L [cm]

350 300 250 200 150 100 50

inner skin friction q

is

[kN/m

2

]

pile wall

section a

section b

section 1

section 2

section 3

Figure 3. Distribution of the inner and outer shaft friction q

is

and q

s

for

different load levels in non-cohesive soils.

Figure 4 shows the vertical displacement of the soil on the

lowest two pile diameters exemplary for the second test series.

Figure 4. Distribution of the vertical displacements in the soil at the pile

toe in the second test series in non-cohesive soils.

There an inhomogeneous distribution could be identified.

Near the inner pile shaft the vertical displacement is much

higher than in the middle of the soil plug. This distribution

occurs during driving independently of all investigated

boundary conditions in the second test series. It is another

indication that the load transfer takes place by the inner shaft

friction and not by an additional base resistance underneath the

soil plug. This assumption can also be supported by the

comparable distribution of the inner and outer shaft frictions,

see also in Figure 3. For a monolithic approach the vertical

displacement had to be more constant which could not be

observed. Furthermore the tests show that these results in non-

cohesive soils cannot be transferred easily to cohesive soils. It