2366

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The best compliance for the adaption factors was found by a

hyperbolic correlation, see Eq.4 and 5.

5.4

Comparable Calculations

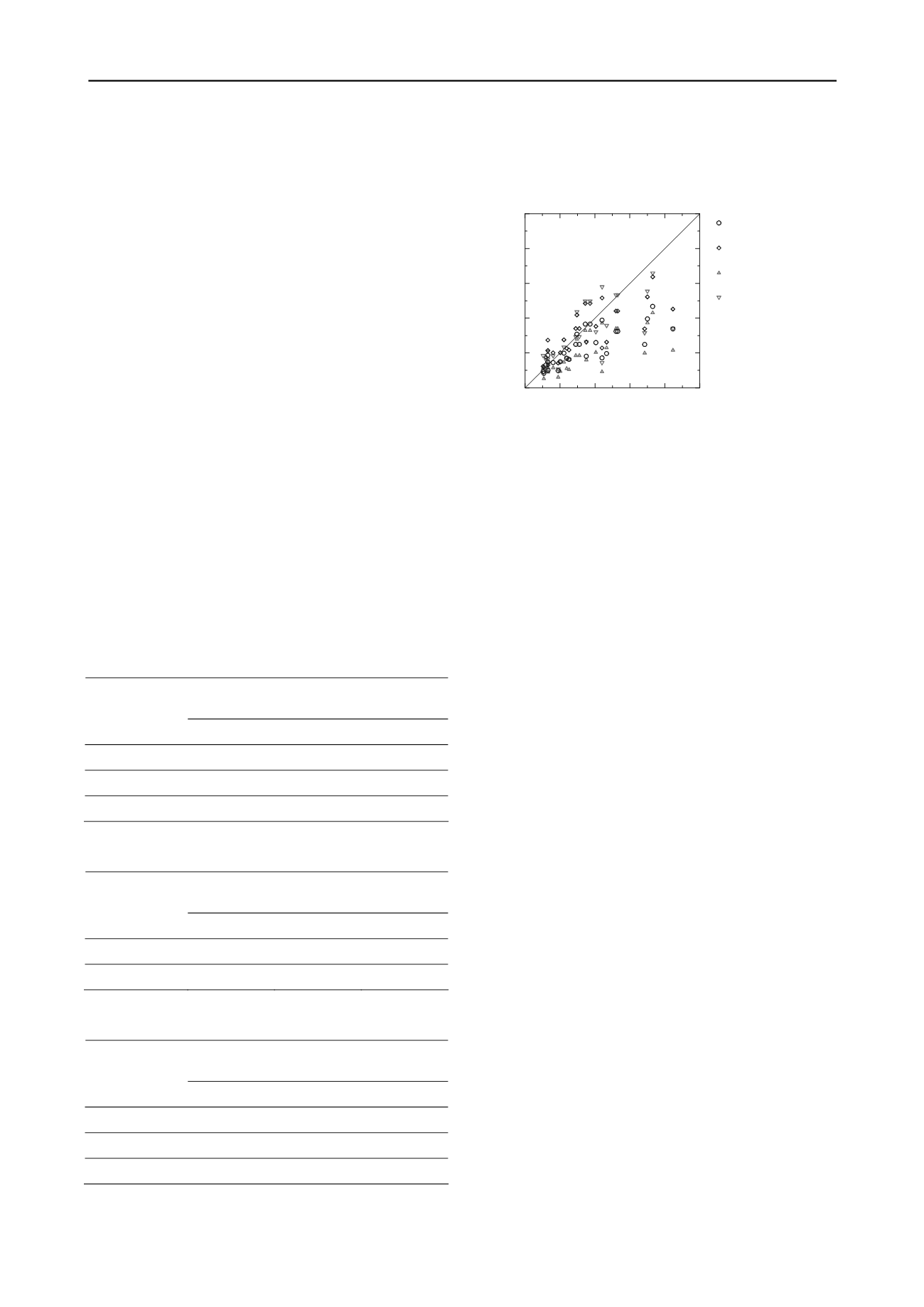

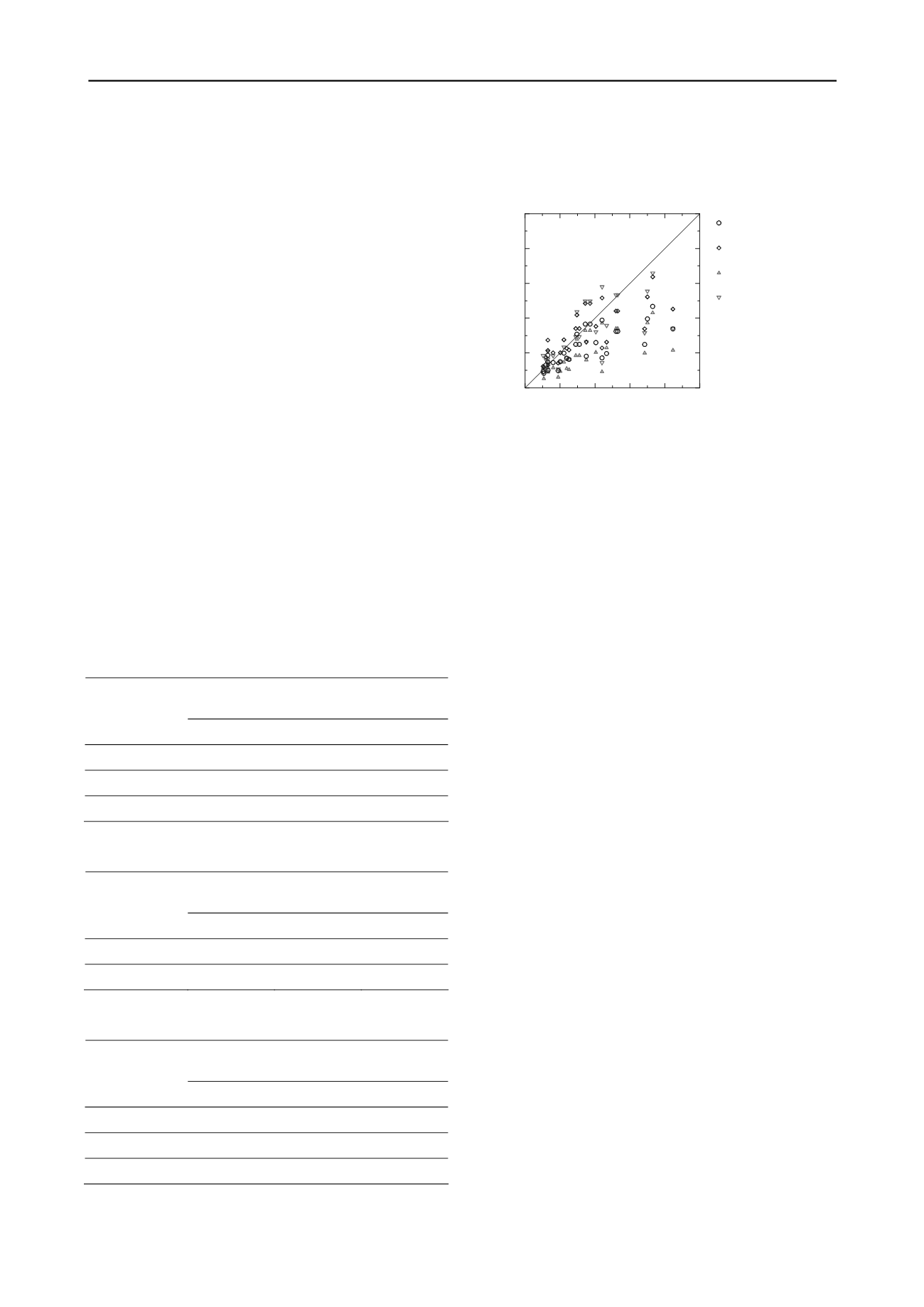

Figure 7 gives an overview of the caclulation results of both

methods compared with the results of the pile load tests.

a

D

b

e

2.1

95.0

D

63.0

(4)

0

2

4

6

8

10

R

m

[MN], static pile load test

0

2

4

6

8

10

R

cal

[MN], calculation methods

calculation method 1,

10 % quantile

calculation method 1,

50 % quantile

calculation method 2,

10 % quantile

calculation method 2,

50 % quantile

a

s

e

1.1

(5)

D

a

: outer pile diameter

5.3

Calculation Method 2

Calculation method 2 is based on an analysis of 28 static pile

loading tests with pile diameters up to D = 1.2 m. In contrary to

calculation method 1 this method derived new values of

experience for each part of pile resistance for the 10 % and the

50 % quantile. Eq.6 gives the basic equation.

s ks a ka is kis k

A qA q A qR

,

,

,

(6)

R

k

: characteristic pile resistance

q

is,k

: characteristic inner pile skin friction after Table 1

q

a,k

: characteristic pile toe pressure of the pile contact

area after Table 2

Figure 7. Calculation results for the characteristic pile resistance R

cal

of

both calculation methods in comparison to results R

m

of static pile load

tests

Figure 7 shows that the requirements of the calculation

methods for the 10 % and 50 % quantile are fully accomplished.

Further calculations and variations of parameters are given in

Lüking 2010.

q

s,k

: characteristic outer pile skin friction after Table 3

A

is

: inner shaft area of the pile

A

a

: contact area of the pile

A

s

: outer shaft area of the pile

This method is valid for pile diameters from 0.3 m up to 1.2

m only in non-cohesive soils. The first values of the experiences

in the following tables are the 10 % quantile and the second are

the 50 % quantile.

6 SUMMARY

Table 1. Values of experience for the characteristic inner shaft friction

is,k

depending on the pile settlement and the resistance of the CPT

The load transfer inside a plug of an open-ended displacement

pile was investigated by experimental, numerical and statistical

methods. It was shown that the load transfer takes place by

compression arches. A fully plugged soil could not be

identified.

q

Characteristic inner shaft friction q

is,k

[kN/m

2

]

at a cone penetration resistance q

c

[MN/m

2

]

Settlement s

7.5

15

≥ 25

s = 0.035•D

a

15/

÷ 35/

35/

÷ 55/

50/

÷ 67.5/

s = 0.1•D

a

30/

÷ 50/

60/

÷ 80/

90/

÷ 100/

with

= 2•PLR, see Eq. 2

7 REFERENCES

API RP 2A-WSD 2007.

Recommended Practice for Planning,

Designing and Constructing Fixed Offshore Platforms - Working

Stress Design

, 21st Edition, American Petroleum Institute,

Washington

Brucy F., Meunier J. and Nauroy J.-F. 1991.

Behavior of Pile Plug in

Sandy Soils during and after Driving.

Proceedings of the 23rd

Offshore Technology Conference, OTC 6514, Vol. 1, pp 145-154

Table 2. Values of experience for the characteristic pile toe pressure q

a,k

epending on the pile settlement and the resistance of the CPT

Dijkstra J., Broere W., and van Tol A. F. 2006.

Numerical Investigation

into Stress and Strain Development around a Displacement Pile in

Sand.

Proceedings of the 6th European Conference on Numerical

Methods in Geotechnical Engineering. NUMGE 06. pp 595-600

d

Characteristic pile toe pressure q

a,k

[kN/m

2

] at a

cone penetration resistance q

c

[MN/m

2

]

Settlement s

7.5

15

≥ 25

s = 0.035•D

a

650

÷ 1.200

1.300

÷ 1.750 1.750

÷ 2.800

s = 0.1•D

a

1.100

÷ 2.000 2.000

÷ 3.000 2.800

÷ 4.800

Empfehlungen des Arbeitskreises „Pfähle“ EA-Pfähle 2012.

Empfehlungen des Arbeitskreises „Pfähle“; 2. Edition, Ed.

Arbeitskreis „Pfähle“ of the German Society of Geotechnics. Ernst

& Sohn. Berlin

Jardine R. J., Chow F. C., Overy R. F. and Standing J. R. 2005.

ICP

Design Methods for Driven Piles in Sands and Clays.

Thomas

Telford, London

Kempfert H.-G. 2009. Pfahlgründungen. Chapter 3.2 in: Grundbau-

Taschenbuch. 7th edition. Part 3. Ernst & Sohn. Berlin. pp 73-277

Table 3. Values of experience for the characteristic outer shaft friction

s,k

depending on the pile settlement and the resistance of the CPT

Lüking J. 2010.

Tragverhalten von offenen Verdrängungspfählen unter

Berücksichtigung der Pfropfenbildung in nichtbindigen Böden.

Schriftenreihe Geotechnik, University of Kassel, Issue 23.

q

Lüking J. and Kempfert H.-G. 2012.

Untersuchung der Pfropfenbildung

an offenen Verdrängungspfählen.

Bautechnik 89, Issue 4, pp 264-

274.

Characteristic outer shaft friction q

s,k

[kN/m

2

] at

a cone penetration resistance q

c

[MN/m

2

]

Settlement s

7.5

15

≥ 25

s

g*

15

÷ 25

30

÷ 50

50

÷ 70

s = 0.1•D

a

20

÷ 30

35

÷ 60

55

÷ 75

with s

g*

[cm] = 0.5•R

s,k

[MN] ≤ 1 [cm]

Paik K.-H. and Lee S.-R. 1993.

Behavior of Soil Plugs in Open-Ended

Model Piles Driven into Sands.

Marine Georesources and

Geotechnology, Vol. 11, pp 353-373

Raffel M., Willert C., Wereley S. and Kompenhans J. 2007.

Particle

Image Velocimetry - A Practical Guide.

Second Edition, Springer-

Verlag, Berlin Heidelberg New York

White D. J., Schneider J. A. and Lehane B. M. 2005.

The Influence of

Effective Area Ratio on Shaft Friction of Displacement Piles in

Sand.

Proceedings of the International Symposium on Frontiers in

Offshore Geotechnics, Balkema, Rotterdam, pp 741-747