2361

Technical Committee 209 /

Comité technique 209

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

8

Principal Stress ratio

=

1

/

3

Axial strain

1

(%)

Laboratory drained biaxial test

Simulation A=0.60 (rough)

Simulation A=0.36 (rough)

Simulation A=0.36 (smooth)

Ottawa sand,

3

=69.4 kPa

Soil properties:

C

u

=1.4, D

50

=0.22mm, e

ini

=0.54, I

d

=0.87

Model parameters:

CSL: e

c

=0.64-0.014(p/101)

0.75

,

c

=36

o

Dilation: tan

=A(1-exp

sign(

)8|

|

0.75

)

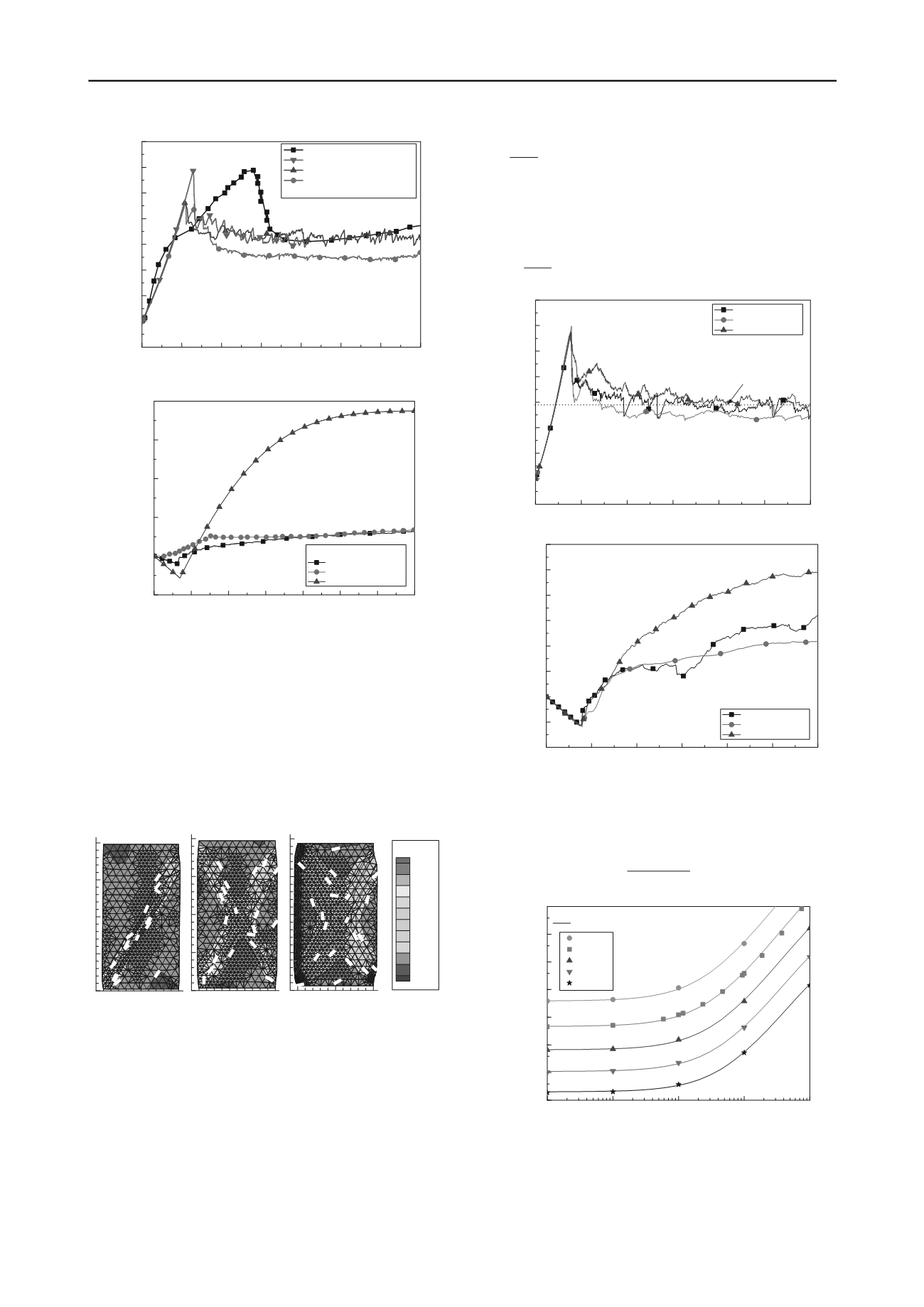

Fig. 3 Biaxial test result of Ottawa sand simulated by FEM

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.04

0.00

-0.04

-0.08

-0.12

-0.16

Volumetric strain

v

Axial strain

1

Ottawa sand,

3

=69.4 kPa

Numerical bi-axial test

Laboratory bi-axial test

Single element test

Fig. 4

v

-

1

relation in biaxial test

Strain localization is critical in explaining some laboratory test

results where after the peak, the deviatoric stress,

q

, often decreases

to a stable value much earlier for axial strain than volume strain

(Samieh and Wong 1997; Salgado et al. 2000; Alshibli et al. 2003).

In Alshibli et al. (2003), the stress starts to oscillate around a stable

value after 10% axial strain, whilst the volume strain continuously

increases even over 25% axial strain. Once a “central” shear band

of soil at the critical state is formed, the apparent shear strength of

whole sample reaches the critical value. However the volume of

whole sample still increases with yielding of soil at the margins of

the shear band (Fig. 5).

0.52

0.54

0.54

0.54

0.54

0.56

0.56

0.56

0.56

0.58

0.58

0.58

0.58

0.6

0.6

0.6

0

50

100

0.52

0.54

0.54

0.54

0.54

0.54

0.54

0.56

0.56

0.56

0.56

0.56

0.56

0.56

0.56

0.58

0.58

0.58

0.6

0

50

100

0.52

0.52

0.54

0.54

0.54

0.54

0.56

0.56

0.56

0.56

0.56

0.58

0.58

0.58

0.58

0.58

0.58

0.58

0.6

0.6

0.6

0

50

100

e

0.7

0.68

0.66

0.64

0.62

0.6

0.58

0.56

0.54

0.52

0.5

Fig. 5 Void ratio field: (a)

1

=2%; (b)

1

=3%; (c)

1

=9%

The geometry of the specimen affects the shearing behavior.

Biaxial simulation results with different sample aspect ratios are

shown in Fig. 6. The

1

-

1

relation is nearly identical in all three

cases. However, the

v

-

1

relation is dependent on the aspect ratio of

the soil specimen and the shape of shear band formed.

5 BEARING CAPACITY OF A FOUNDATION ON SAND

The bearing capacity of circular plate on sand is analyzed by both

limit analysis (using the ABC program, Martin 2004) and LDFE. In

soil with self-weight the bearing capacity factor N

is often coupled

with N

q

although the two parts are not simply superposable. An N

q

-

N

bounding index

is defined as:

surf

D

q

(8)

where

D is a representative self-weight stress beneath the footing

and q

surf

is the surface surcharge. The coupled N

q

and N

bearing

capacity can be characterized by an integrated bearing capacity N

q

that varies with

and is defined as:

u

q

surf

q

N

q

(9)

0.00

0.01

0.02

0.03

0.04

0.05

0.06

0

1

2

3

4

5

6

7

8

Principal Stress ratio

=

1

/

3

Axial strain

1

100 X 300 Sample

100 X 200 Sample

100 X 100 Sample

Bi-axial test with fully rough boundary

e

ini

=0.54, I

d

=0.87,

c

=36

o

tan

=0.75(1-exp

sign(

)3.5|

|

0.75

)

c

= 3.85

(a)

1

-

1

relation

0.00

0.01

0.02

0.03

0.04

0.05

0.06

0.008

0.004

0.000

-0.004

-0.008

-0.012

-0.016

-0.020

-0.024

Volumetric strain

v

Axial strain

1

100 X 300 Sample

100 X 200 Sample

100 X 100 Sample

(b)

v

-

1

relation

Fig. 6 Effect of sample geometry on biaxial shearing behaviour

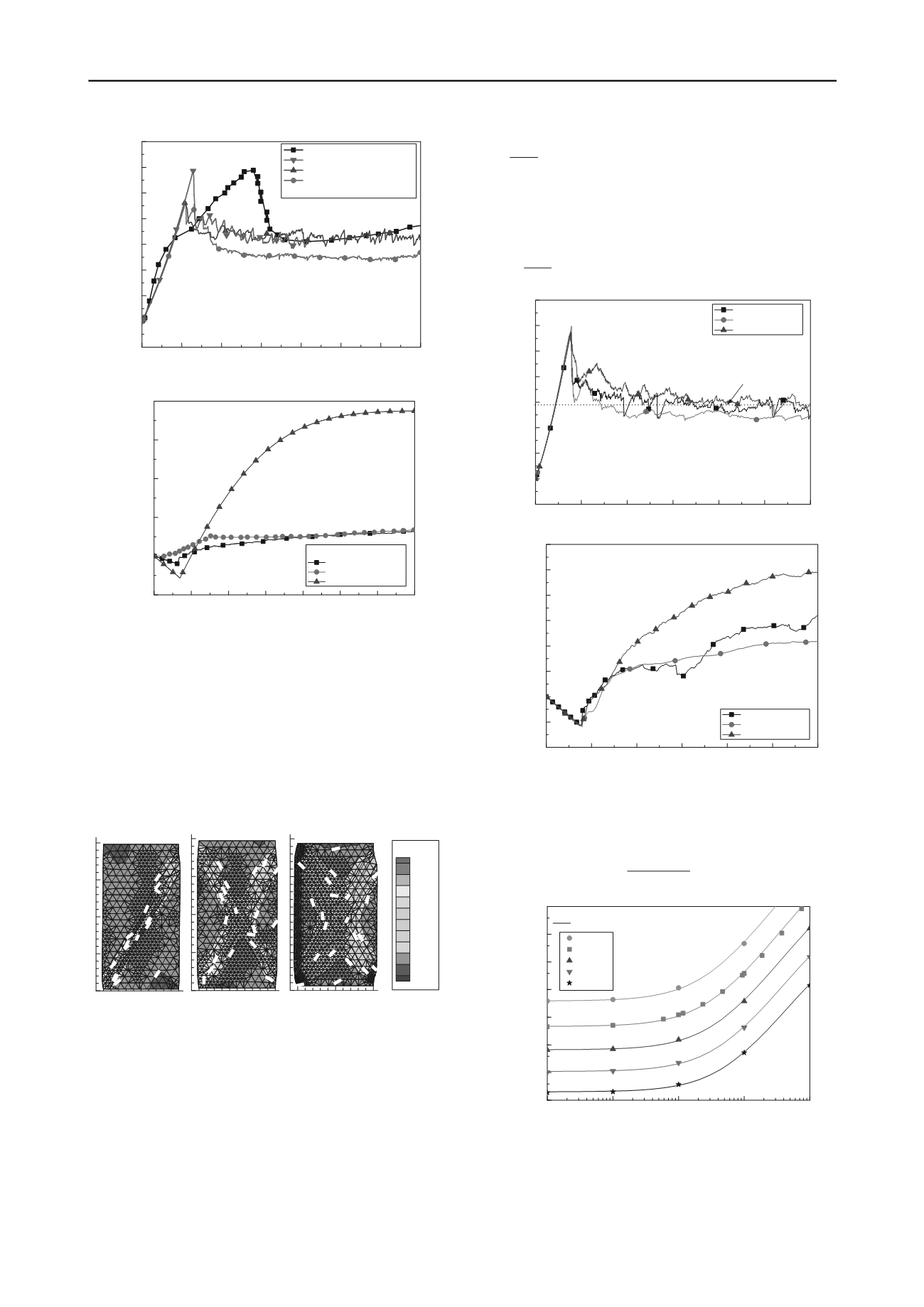

Limit analysis using ABC shows that the integrated N

q

factor for a

rough circular foundation can be approximated as (Fig. 7):

2 tan

(1 0.48 tan

)

1 0.0025

q

N e

(10)

0.01

0.1

1

10

100

8

16

32

64

128

256

512

1024

Integrated bearing capacity factor N

q

=q

u

/q

surf

Boundary condition

=

D/q

surf

=

=36

o

=

=32

o

=

=28

o

=

=24

o

=

=20

o

Limit analysis of circular plate penetration into sand

Best fit lines: N

q

=(1+0.48

tan

/(1+0.0025

))e

2

tan

Fig. 7 Coupled bearing capacity factor N

q

for a circular foundation

Referring to Fig. 7, the integrated N

q

factor approaches a constant

value with the decrease of the N

q

-N

bounding index

. That

ultimate value, e

2

tan

, can be regarded as N

q

. Similarly, the

integrated N

q

of rough strip foundation can be calculated as,