2274

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

flexible mechanism, so that the device moves together with the

ground displacement. A sensor unit covered by a small

aluminum cylindrical case is installed in each segment. The

sensor unit contains the MEMS tilt meter and a geomagnetic

sensor (digital compass, nominal resolution = 0.5 deg) to detect

the direction of unit. Each unit also contains a microcontroller

chip, which control the sensors, and transfer the control

commands and the obtained data to the next units by serial

interfaces. A significant advantage of this device is that it can be

installed quickly into the slope ground being blown with a

hammer, as its diameter is as small as 25 mm. Besides, it can be

installed into a deeper layer of slopes (3-5 m) by connecting the

segments as many as needed.

Unlike conventional sensing devices, such as borehole

inclinometer and extensometer which measures displacements

of slope, measurement with tilt sensors is simple and easy.

However, the translation of the obtained data of tilting angle is

still under consideration. It is because there are few case

histories of early warning with tilt sensors compared to those

with conventional sensors. Therefore, it is essential to observe

the behaviors of tilt angles in prefailure stages of slopes.

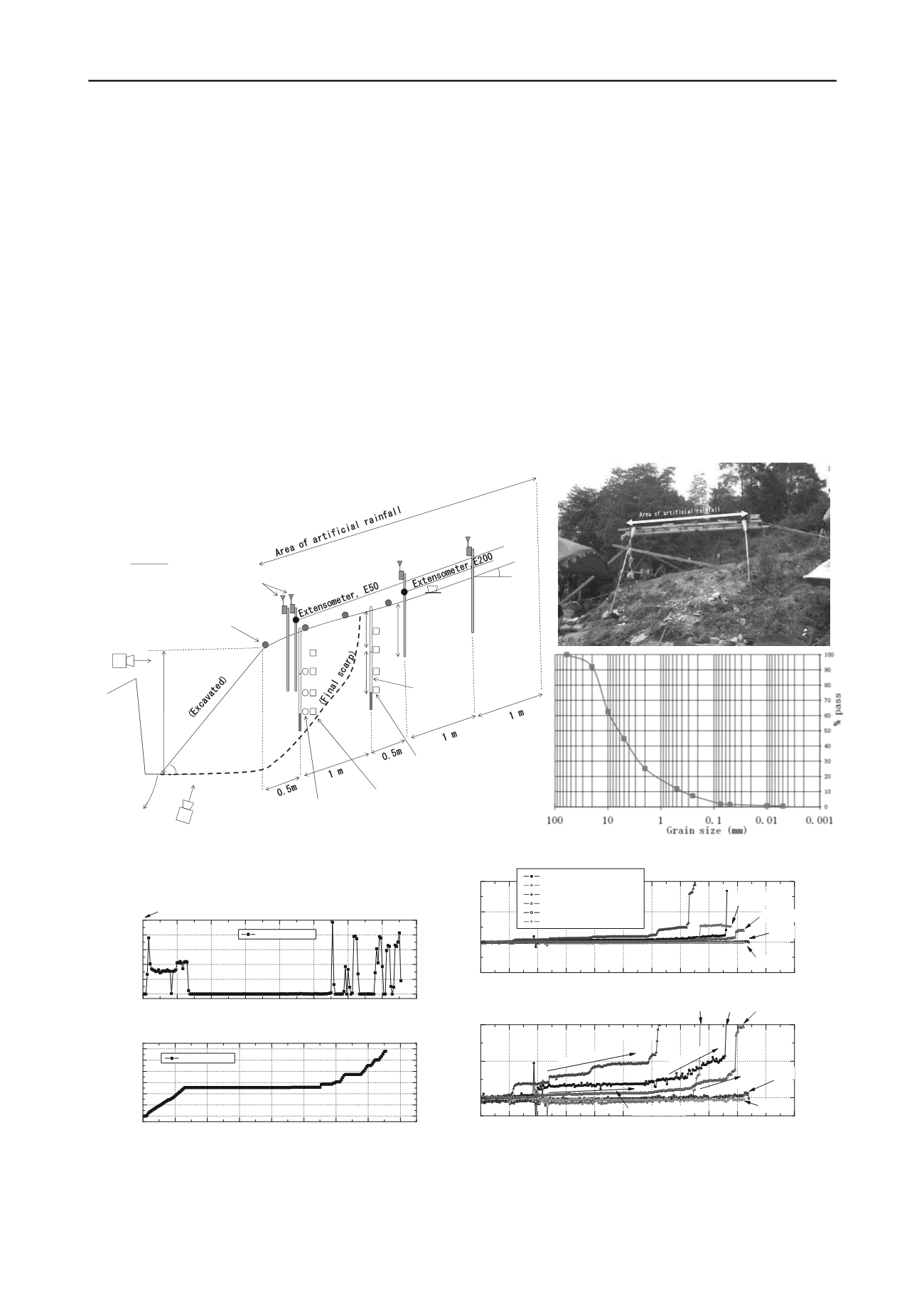

2 SLOPE FAILURE TESTS BY ARTIFICIAL RAINFALL

An artificial rainfall test was conducted on a natural slope of

weathered and loose (N

d

<10 for 10 cm of penetration by

portable dynamic cone penetration tests) andesite deposit in

order to observe its prefailure behaviour. The site is located on

an unstable slope in Taziping, Sichuan Province, China. Figure

2 shows the cross-section and photo of the site together with the

instruments. The slope angle is around 18 degrees, and its lower

end was excavated for a depth of 1.4 m with an angle of 40

degrees. The deposit contains some big rocks with diameter of

300 mm or more. The particle size distribution of component

finer than 100 mm is show in Figure 2. It is a sandy material

containing some gravel and fine particles.

Figure 2 also shows surface tilt sensors (T50-1, T50-2, T200,

and T300), and miniature ground inclinometer (K50 and K150).

The number in the notation of each sensor represents the

distance from the bottom end of slope in cm. Each rod of the

surface tilt sensors was inserted into the ground by 75 cm. Each

miniature ground inclinometer consists of 2 segments with a

length of 500 mm.

Side view:

Deposi t

removed

1. 4 m

Mi ni ature

i ncl i nometer

( 0. 5mx 2uni ts)

Ti l t sensors

T50-1&2

Ti l t sensor

T200

Vi deo

camera

Vi deo

markers

18°

Ti l t sensor

T300

40°

Vi deo

camera

0. 75 m

0. 5 m

0. 5 m

Pore water pressure

sensors, U50

( Depth = 0. 5, 0. 75, 1m)

Vol umetri c water

content sensors, W150

( Depth = 0. 25, 0. 5, 0. 75, 1m)

Rai n

gage

Vol umetri c water

content sensors, W50

( Depth = 0. 25, 0. 5, 0. 75, 1m)

Figure 2. Cross-section, photo, and particle size distribution (finer part than 100 mm) of the site for the artificial rainfall test.

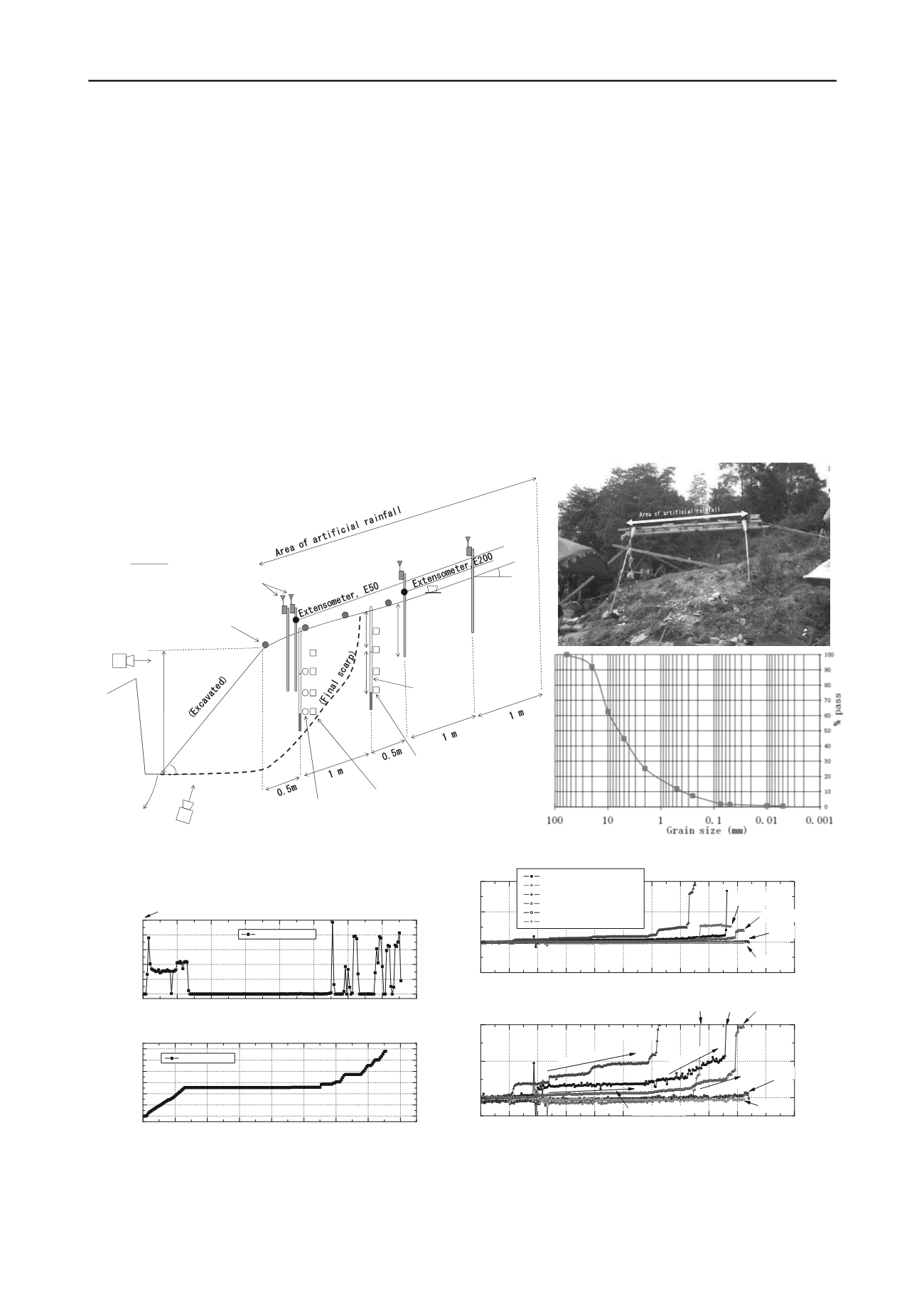

0

4

8

12

16

20

24

28

32

0

10

20

30

40

50

Elapsed time (hour)

Rainfall (mm/ 10min)

Rainfall (mm/ 10min)

2011/ 6/ 29- 11:00

0

4

8

12

16

20

24

28

32

0

200

400

600

800

1000

1200

Elapsed time (hour)

Total rainfall (mm)

Total rainfall (mm)

32 33 34 35 36 37 38 39 40 41 42 43

- 5

0

5

10

K50- upper

Elapsed time (hour)

Tilting angle (deg)

Tilt sensor T50- 1

Tilt sensor T50- 2

Mini- inclinometer K50- upper

Mini- inclinometer K150- upper

Tilt sensor T200

Tilt sensor T300

2011/ 6/ 30- 08:00

T200

T50- 1

T300

T50- 2

K150- upper

32 33 34 35 36 37 38 39 40 41 42 43

0

1

2

0.24 deg/ hour

0.02 deg/ hour

0.4 deg/ hour

0.15 deg/ hour

T50- 2

Elapsed time (hour)

Tilting angle (deg)

2011/ 6/ 30- 08:00

K50- upper

T50- 1 K150- upper

T300

T200

Figure 3. Records of the artificial rainfall. Figure 4. Tilting angles on the slope.