2267

Technical Committee 208 /

Comité technique 208

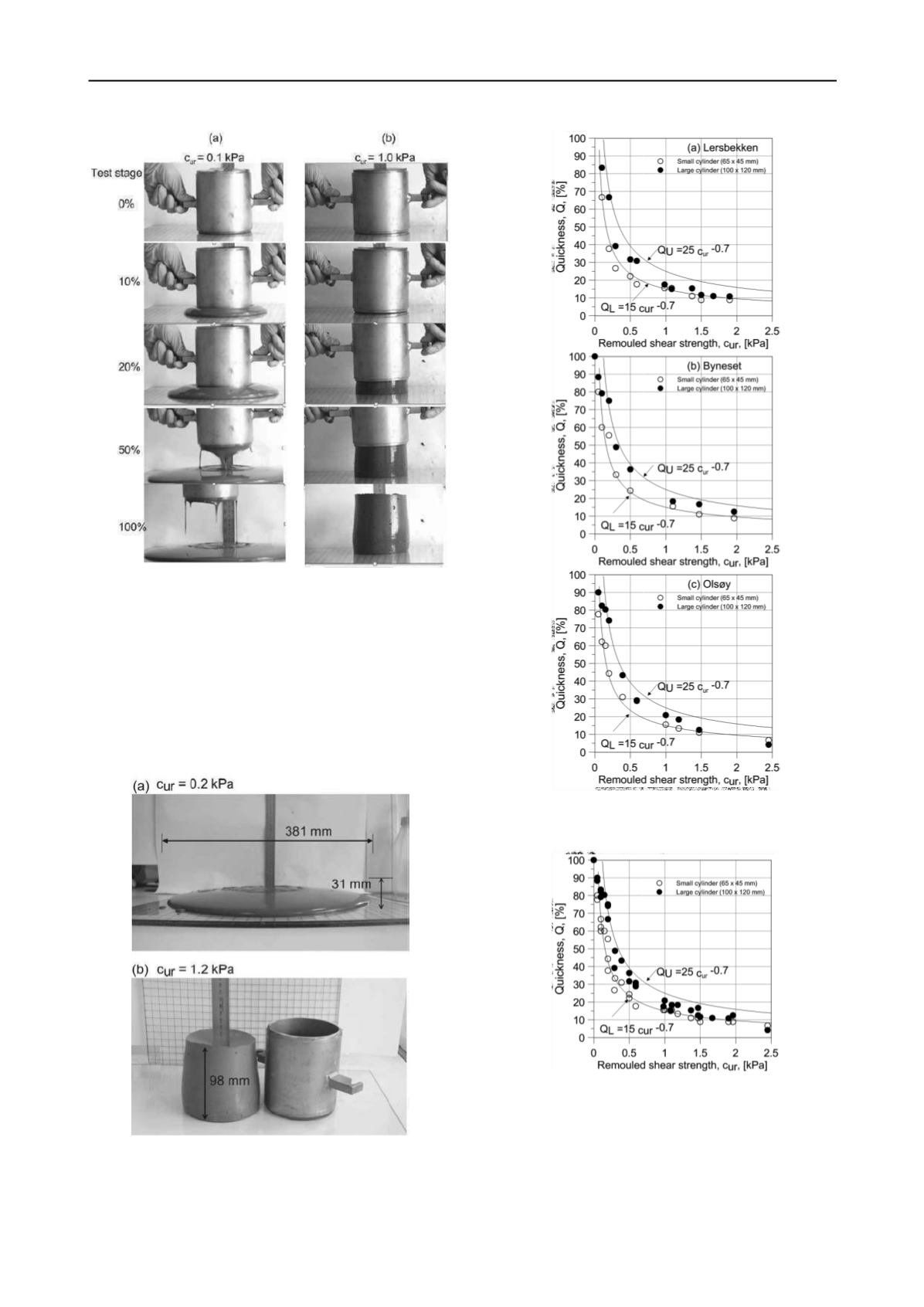

Figure 2. Slump and spread observed from the start to the end of

the Quickness tests for remoulded Byneset clays

(a)

c

ur

= 0.1

kPa and (b)

c

ur

= 1.0 kPa.

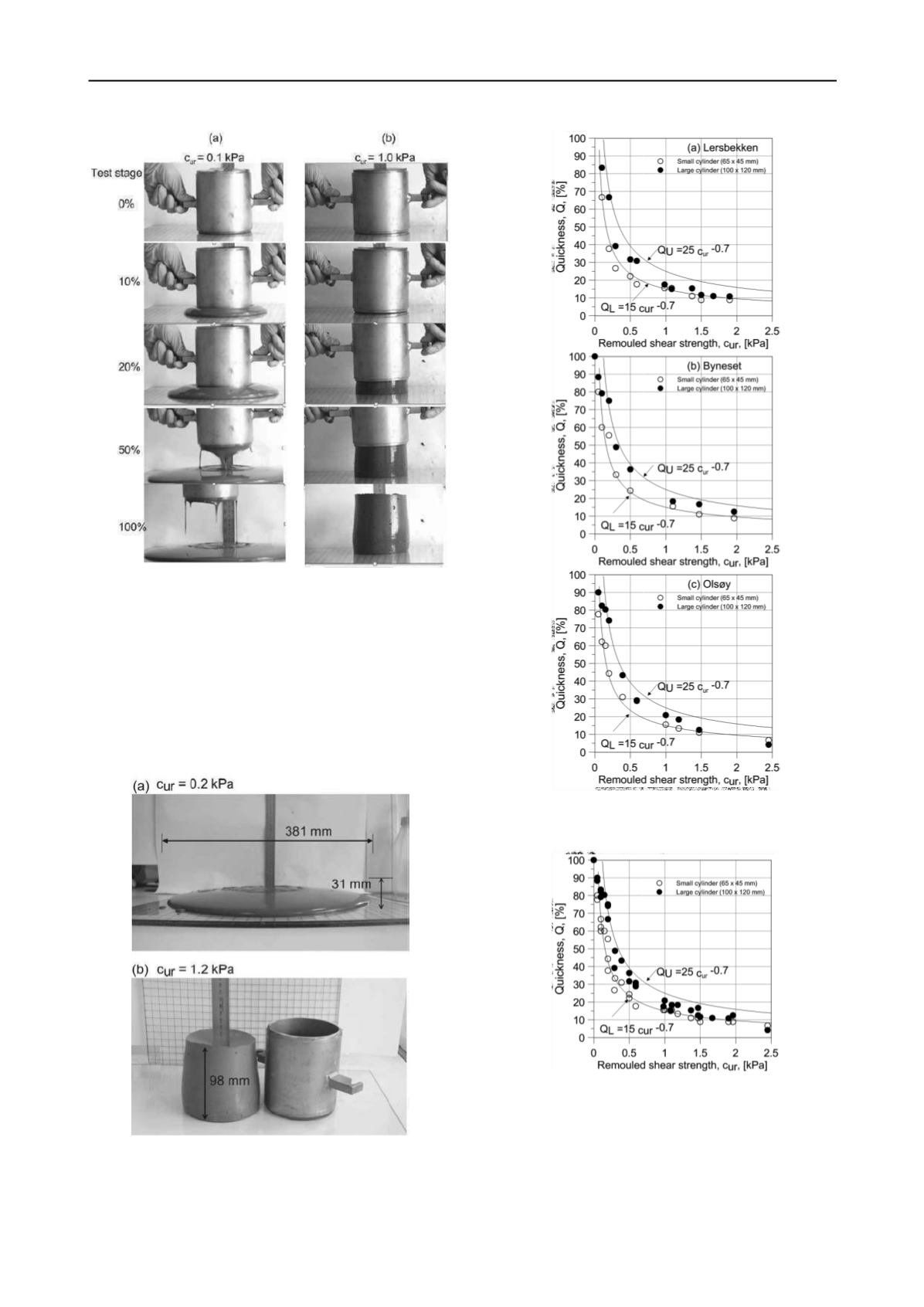

A typical flow and spread behaviour of two remoulded clays

from the Olsøy site are presented in Figure 3. The tests on

Olsøy clay shows that the remolded material with

c

ur

< 0.2 kPa

seemed to be more like a soup, Figure 3(a). As the

c

ur

increases

from 0.2 kPa towards 1 kPa, the remolded material increasingly

showed less viscous behavior and for a

c

ur

> 1.0 kPa little or no

flow is observed, Figure 3(b). This simple test indicates why

soft sensitive clays with a

c

ur

> 1 kPa are less likely subjected to

a large retrogression or run-out.

Figure 3. Flow and spread behaviour of the two remoulded

Olsøy clays having (a) c

ur

= 0.2 kPa and (b) c

ur

= 1.2 kPa.

Figure 4.

Q

versus

c

ur

values registered on soil samples taken

from a) Lersbekken b) Byneset and c) Olsøy landslide locations.

Figure 5. Compilation of

Q

versus

c

ur

values registered on soil

samples taken from the three landslide locations.

Apparently, the flow behaviour of the Lersbekken, Byneset and

Olsøy clay is identical. Figure 4 presents

Q

versus

c

ur

for

various sets of tests on the Lersbekken, Byneset and Olsøy clays

performed with two different cylinder sizes, 100 mm x 120 mm,

65 mm x 45 mm. For the major area of interest, i.e. clay

samples with

c

ur

> 1.0 kPa, material flow was not registered

irrespective of the size of the test cylinders. Accordingly, this

Figure 4.

Q

versus

c

ur

values registered on soil samples

taken from a) Lersbekken b) Byneset and c) Olsøy

landslide locations.

Figure 4.

Q

versus

c

ur

values registered on soil samples

taken from a) Lersbekken b) Byneset and c) Olsøy

landslide locations.