966

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

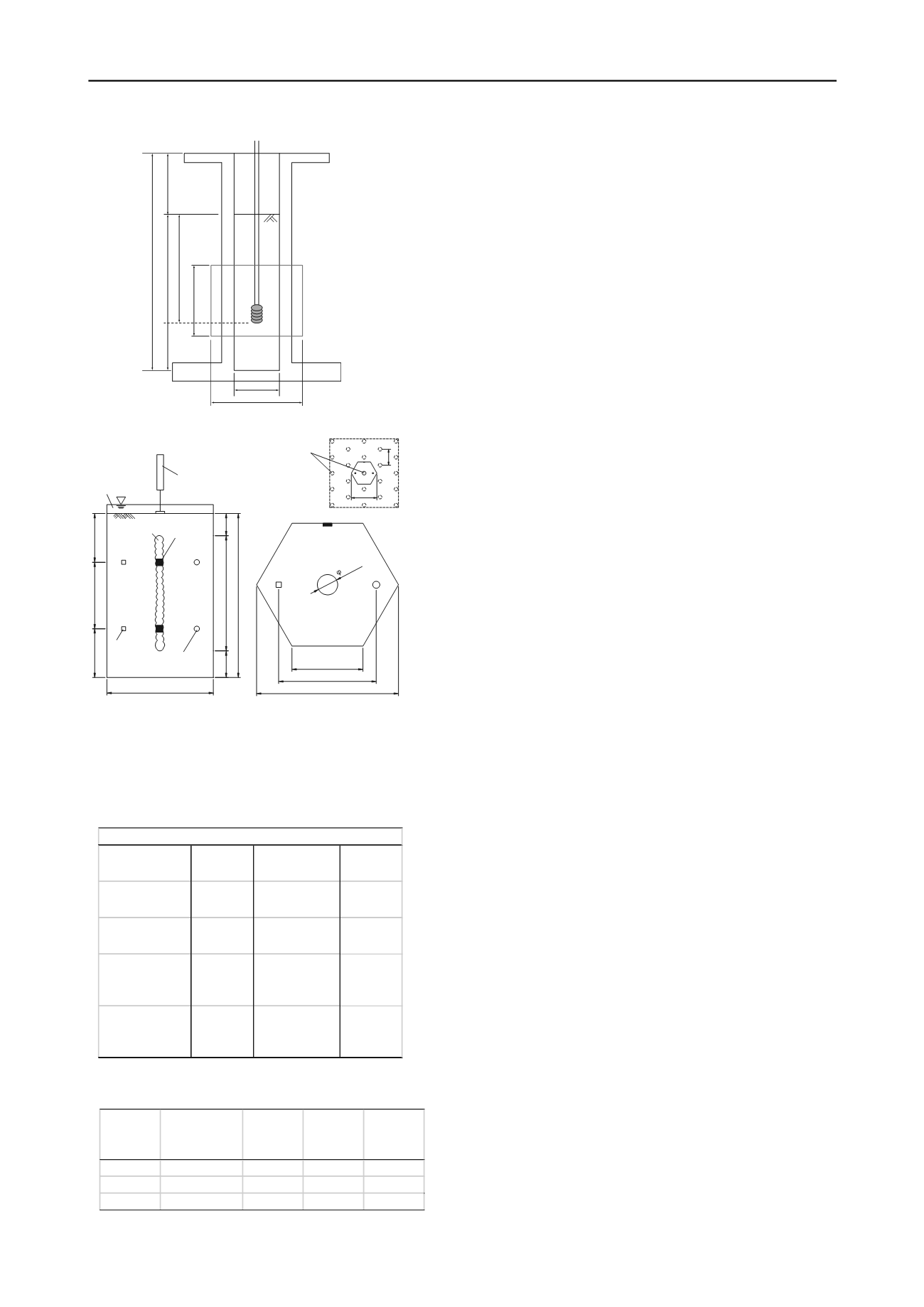

Figure 2. Schematic view of XRCT test setup

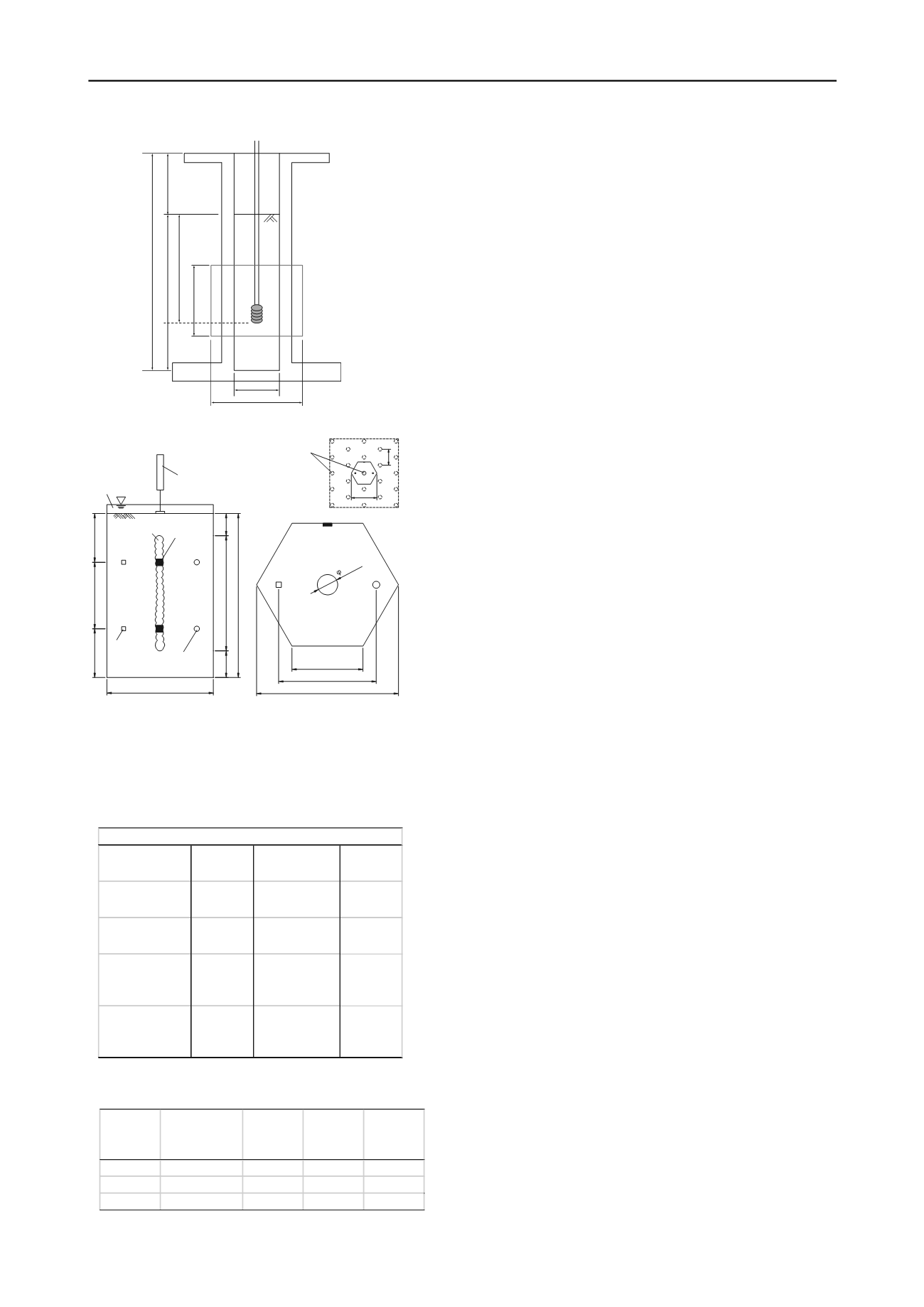

Figure 3. Schimatic view of test setup in centrifuge (CPGs30).

Table 1. properties of Soma Silica Sand #5

Table 2. List of test cases in centrifuge

prepared by air-pluviation targeting the relative density of 50 %

and Soma Silica Sand #5 is used as ground material. The

properties of Soma Silica Sand #5 are shown in Table 1. The

injected grout prepared mixing the Soma Silica Sand #5, the

Kawasaki Clay, Portland cement and water at the ration of

40 %:60 %:12 %:50 % by weight.

60

106

130

254

100

342

442

Injection rod

Scanned area

Unit:mm

As the procedure of XRCT test, the soil container was

mounted on turn table of the XRCT scanner after preparing

model ground and then grout pile was injected in a bottom-up

sequence through the injection rod. All injection and CT

scanning processes are carried out in-situ condition (in-situ

meaning x-ray scanning at the same time as injection) and full

volume of cross sectional images are recorded every two step of

grout injection. The injected volume was controlled to make the

grout pile diameter of 20 mm. The details of the injection

system can be referred in Nishimura et al. 2012. In 1g model

test using miniature model ground as XRCT test in this study, it

was concerned that the uplifting deformation caused by grout

injection will dominate because of lower effective confining

pressure therefore densification effect will not be evaluated

correctly. In order to avoid this effect, 10 kPa of overburden

pressure was applied at tip of injection rod by filling up soil

container above the model ground by stainless cubes with 2 mm

of diameter. Reconstructed volume images were analyzed using

3D V-DIC in order to evaluate the deformation process during

grout injection.

In centrifuge tests, the model ground was prepared as same

procedure as CT test. All the test procedure, saturation of model

ground, injection of grout pile and shaking table test were

carried out under a centrifugal acceleration of 30 G. Viscous

degassed fluid (30 mm

2

/sec of dynamic viscosity) was used as

pore water. The cross section of model ground presents shearing

zone by one grout pile thus small diameter of container presents

small pile spacing or large improvement ratio. Table 2 shows a

list of test cases in centrifuge, in which case CPGd18sA and

CPG30sB models 1.8 m and 3.0 m of pile spacing (in prototype

scale) equivalent to 13.7 % and 4.9 % of improvement ratio and

case CPG30nA models ground without grout injection,

respectively. As a shaking condition, sinusoidal wave with 2 Hz

of frequency (in prototype scale) and 50 waves are applied

increasing the amplitude of vibration. During the shaking,

horizontal earth pressure, response acceleration of ground and

pore water pressure was measured.

3

RESULTS AND DISCUSSIONS

3.1 X-ray tomography

Figure 4 presents density distribution of the model ground at

each scanning steps as a result of the x-ray tomography. After

grout injection, the increase of ground density can be observed

at the side of the grout piles with increase of 25 % of relative

density thus densification effect may occur mainly at lateral side

o grout piles. The distribution of vertical and horizontal

displacement as results of DIC analysis is shown in Figure 5.

The upper line of Fig. 5 presents incremental vertical

displacement between initial-2

nd

injection (Step A), 2

nd

-4

th

injection (Step B) and 4

th

-6

th

injection (Step C) and the lower

line presents incremental horizontal displacement, respectively.

Horizontal displacement is localized in the area around the

grout pile through all the steps. On the other hand, vertical

displacement beneath the grout pile can be observed at Step A

injecting deeper position and the downward displacement is

decrease with injecting position shallower. These features

indicate that the mechanism of ground deformation caused by

grout injection can be considered as a cavity expansion for deep

injection and cone uplift for shallow injection. The map of

maximum shear strain and volumetric strain calculated from

DIC results are shown in Figure 6. The general tendency

observed from Fig. 6 is that shear strain is localized around the

model ground

horizontal crossection

LVDT

model ground

vertical cross-section

grout pile

DT1

A11

A12

P1

P2

E1

E2

puressure cell

pore water

pressure cell

acceleration

gage

0.69 (23)

3.5 (116)

11.1 (370)

7.8 (260)

1.8 (60)

3.3 110)

(

4.5 (150)

3.3 (110)

3.5 (116)

1.7 (58)

2.4 (80)

digassed water

3.0

(100)

grout pile

3.5 (116)

plane viwe of a improved site

1.5(50)

units:[

m] in prototype scale ([mm] in model scale

)

Specific gravity,

G

s

2.65

Median particle

size, D

50

0.35 mm

Maxumum void

ratio, e

max

1.115

Coefficient of

uniformity, Uc

1.5

Minumum void

ratio, e

min

0.71

Shear resistance

angle, φ' (from

Dr=50 %)

36.1°

Shear resistance

angle, φ' (from

Dr=90 %)

40.4°

Soma Silica Sand #5

Case

Improvement

ratio (%)

Pile

spacing

(m)

Pile

diameter

(m)

Relative

density

(%)

CPGd18s

13.7

1.8

0.7

55

CPGd30n

-

-

-

41.3

CPGd30s

4.9

3

0.7

70.4