959

Technical Committee 104 /

Comité technique 104

delivered to the centrifuge. Any changes were made by hand

during the centrifuge flight. The on board instrumentation is

monitored to ensure that a consistent and appropriate flow was

being delivered to the pile. The position of this control tap

governed the peak flow rate and was unchanged throughout a

single installation.

3.4 Maintaining balance

The centrifuge at Cambridge is balanced using a fixed mass

counterweight. This is cumbersome to change during a test

week and cannot be changed mid-flight. Therefore the mass of

the experimental package had to remain constant throughout the

centrifuge test, despite adding water to the package at very high

flow rates.

A passive standpipe system was designed in order to drain

excess water out of the experimental package into the centrifuge

chamber. The standpipe was positioned within the sand body

near the edge of the container – remote from any pile locations.

A set of holes at the base of the standpipe linked the water level

in the standpipe to the water table in the sand body.

Holes at the top of the standpipe allowed water to drain out

of the package through a set of drainage pipes. If the water level

exceeded the design water level at any point, water would exit

the package by draining through these top holes.

To monitor the success of the standpipe, pore pressure

transducers were used. A series of these were positioned in the

sand body to monitor the pore pressures around an advancing

pile installation. Additionally, these transducers provided

knowledge of the water table position in the model. A further

transducer was placed at the base of the standpipe to check that

the drainage system was functioning.

3.5 Testing program

All centrifuge tests to be presented in this paper were completed

at an acceleration of 60g. According to length scaling, this

modelled a 720 mm diameter, close-ended tubular pile installed

to a depth of 11.4 m. For the purpose of future discussion, all

future units will be at the model scale.

A soil stabilisation loop was completed before the first

installation in order to prevent excessive change of the sand

body between the first and subsequent flights. Following this,

multiple pile installations were completed in a single flight

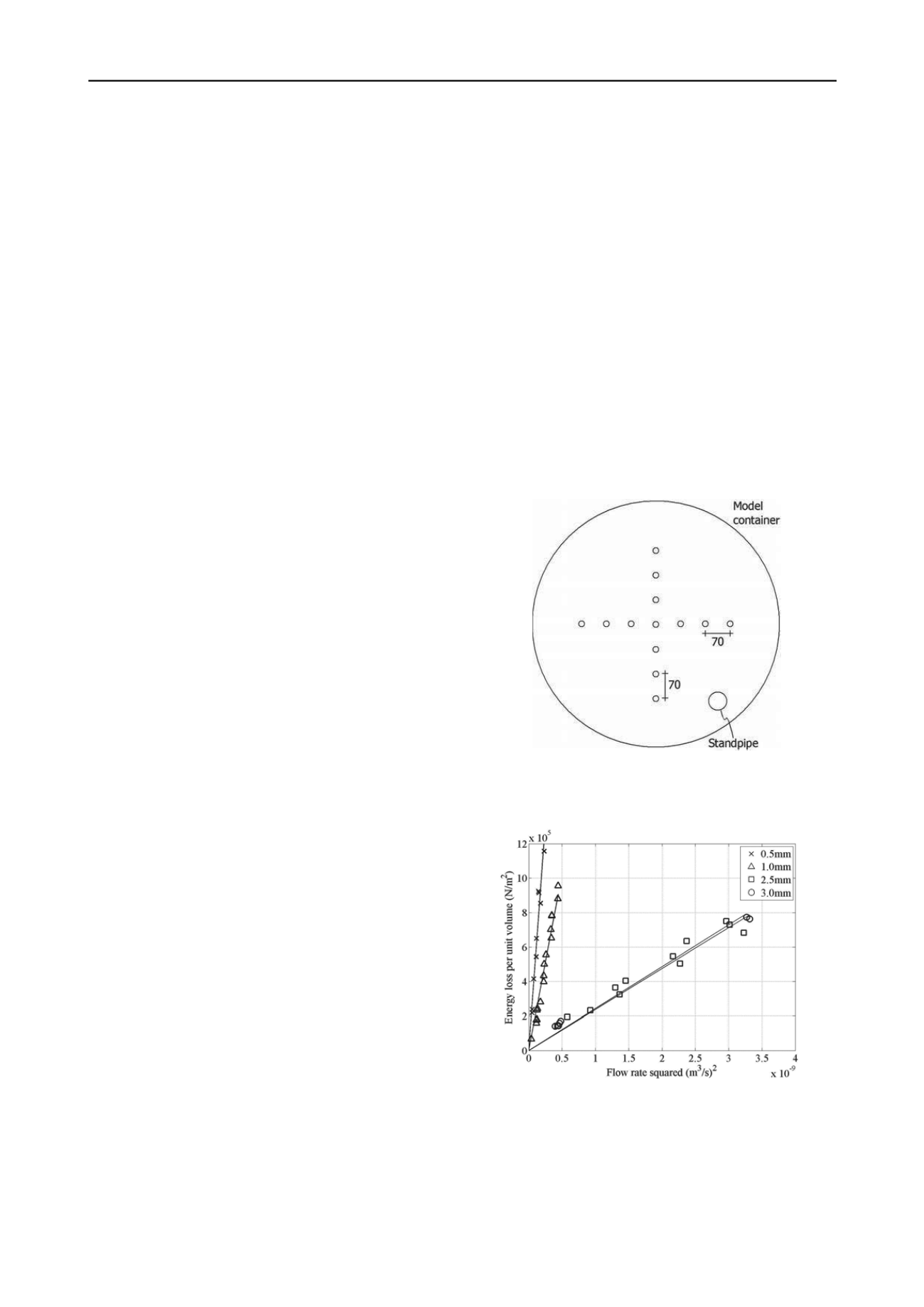

using the centre's 2D actuator (Haigh et al. 2010). Piles in a

single flight were spaced at 140 mm (12D

p

), but final pile

spacing was close to 70 mm (6D

p

). A typical pile layout is

shown in Figure 3.

The nozzle at the pile toe was changed between flights to

investigate the importance of the nozzle layout. The nozzles

restricted the peak achievable flow rate, in addition to attracting

further pressure losses at the pile toe.

4 RESULTS

The discussion of results will be split into sections to discuss the

success of the water injection system and pile installation

information.

4.1 Water injection system

The novel water injection system proved to be successful. The

feeder pressure from the mains water supply provided a

relatively steady pressure of 200 kPa during testing. The flow

rate to the beam was controlled using the manual control tap; a

variety of flow rates were possible using this simple control.

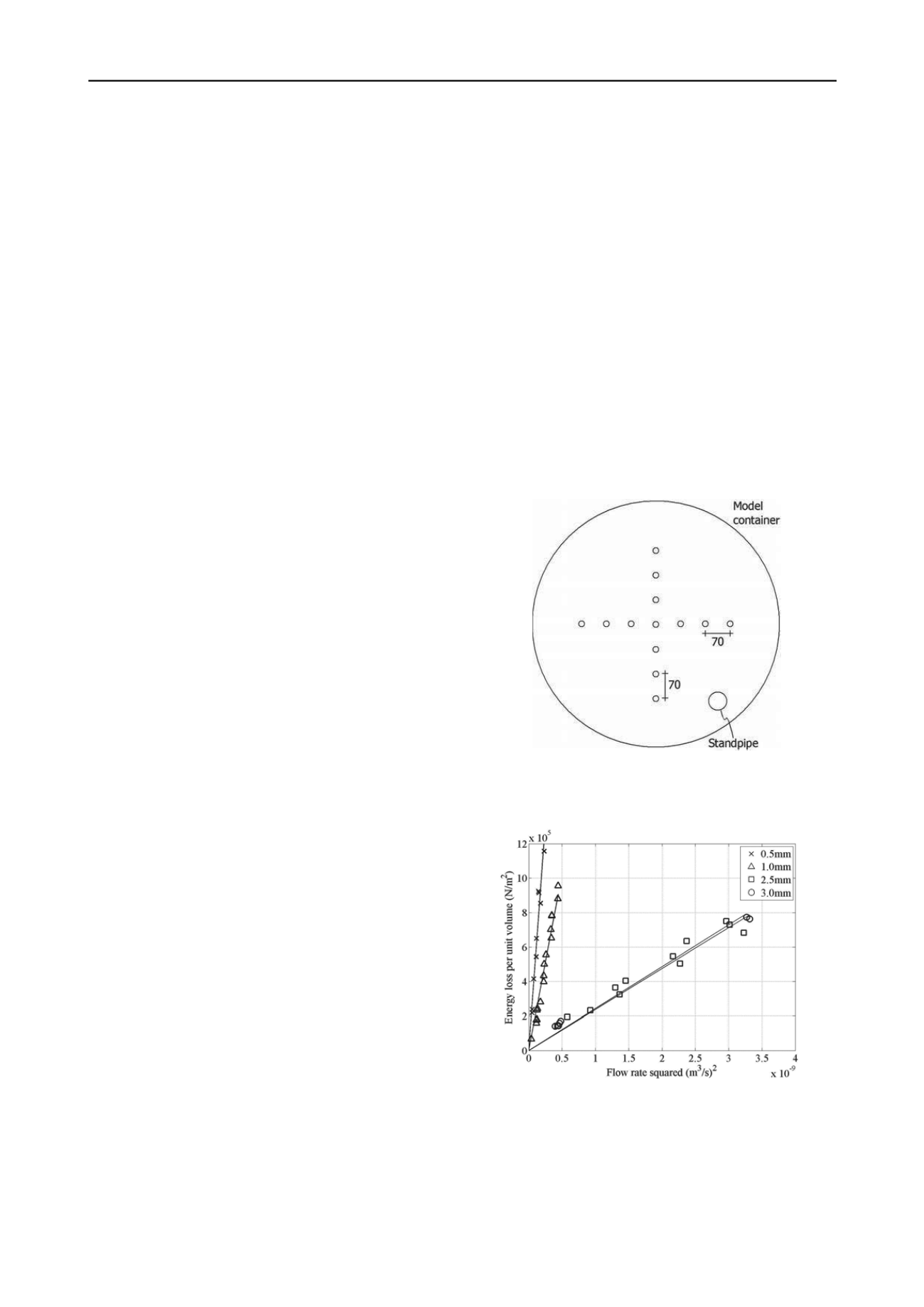

Multiple flow rates were essential in order to calibrate the

loss factors in the pipe between the measurement point and the

pile toe. Increased confidence in the calculation could be

achieved if more unique flow rates were tested. Figure 4 shows

a plot of the data points used to find the loss factors for four

different nozzle sizes.

On comparing these flow test results, the effect of changing

the nozzle becomes immediately apparent. As predicted, the

smallest nozzle attracts the largest pressure losses; denoted by

the steeper gradient lines of best fit in the figure. This is a

similar result as monitoring the pressure loss from small orifice

plates blocking flow through a pipe and highlights how the loss

factors are dominated by the nozzle used.

With the larger nozzle sizes, larger flow rates were

achievable with smaller losses. There is little to no difference

between the 2.5 mm and the 3.0 mm diameter nozzles due to

their similar size to the feeder pipe. The 2.5 mm nozzle acts as

a continuation of the feeder pipe, and the 3.0mm nozzle

effectively reduces the sharpness of the pipe exit; both have

little effect on the pressure loss.

4.2 Maintaining balance

The standpipe system maintained the balance of the centrifuge.

As shown in Fig 5, the pressure of the standpipe remains

constant throughout the flight plotted. The two dotted lines for

the standpipe PPT represent brief periods where the instrument

failed during the test.

Figure 3. Typical pile layout in a single test week. At least four flights

are completed at 140 mm pile spacing in each flight.

Figure 4. Energy loss per unit volume of water passing between the

pressure line and the termination nozzle. All lines of best fit shown

have a correlation R

2

value greater than 0.94. The smallest diameter

nozzle attracted the largest loss, as expected. The 2.5 mm and 3.0 mm

nozzles attracted the same loss due to their relative size to the feeder

pipe.