958

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

reduced further. There is no longer a reliance solely on the

water flow to install the pile. Instead the pile is jacked and the

water injection is used to reduce the required installation loads.

Flow rates for this method reduce to less than 300 litres per

minute, and depend on the size and type of pile being installed.

The aim of water injection is to aid pile installation with

minimal impact to the surrounding ground. Water injection

should only be required during periods of high pile installation

loads. During these phases, high water injection rates would be

required to reduce the installation loads. Once the installation

loads are sufficiently reduced, the flow rate can be reduced

unless pile loads begin to increase again.

Despite the variety of full scale testing completed, there is

still uncertainty over the water injection technique. The main

unknown is the governing mechanism. Some options have been

suggested, most recently the scour system outlined by Schneider

et al. (2008), however further research is required to investigate

the technique further.

3 CENTRIFUGE MODELLING

Initially, the aim of the centrifuge testing was to find an effect

on the pile installation load when using the water injection

system.

3.1 Model construction

A body of fine sand was prepared to a relative density of 80 %

in a centrifuge container, 850 mm in diameter, to a depth of 320

mm. This was saturated from the base with de-aired water.

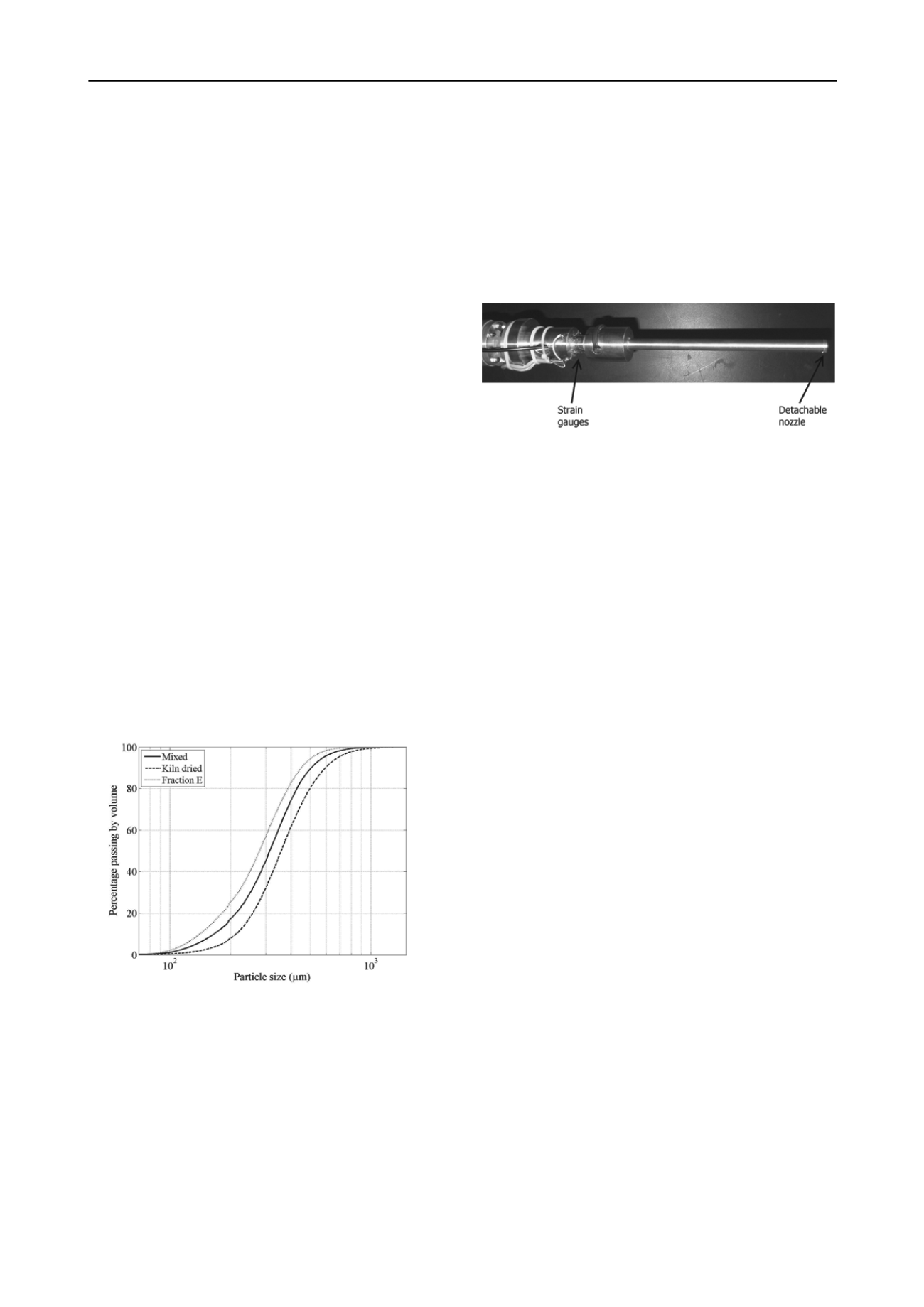

The sand was prepared so that it possessed a low

permeability by mixing fine Fraction E silica sand with a

commercially available builders sand. To ensure continuity

between tests, the sand was repeatedly sampled and the particle

size distribution (PSD) was found for different batches using the

Single Particle Optical Sizing (SPOS) technique. Figure 1

shows the particle size distribution of the mixed sand compared

with the Fraction E and builders sand components.

Figure 1. PSD comparison of the mixed sand for testing with standard

sand types, Fraction E and a builders sand.

3.2 Model pile

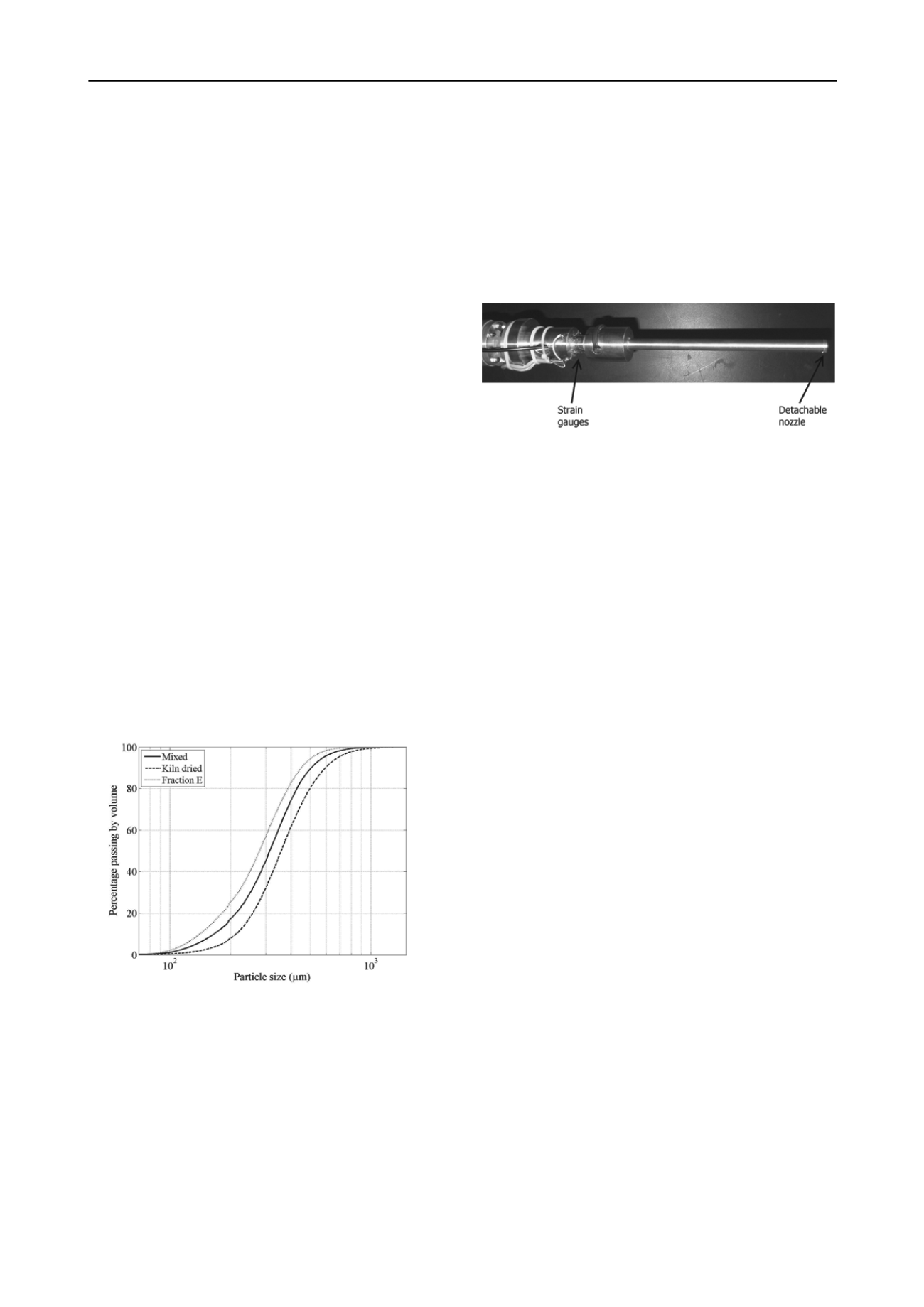

A bespoke instrumented model pile was constructed for the

testing program. A stainless steel tube of 12 mm outside

diameter was used, with a water delivery pipe running through

the centre. Stainless steel was chosen due to its strength,

hardness and resistance to corrosion – preventing buckling

during testing or surface abrasion over multiple installations.

This ensured consistency over all the installations. A

photograph of the pile is shown in Figure 2.

Strain gauges were used to monitor the axial load at the pile

toe and the pile head. Two full Wheatstone bridges were used

at each location.

The water delivery pipe was a 2.5 mm internal diameter

plastic pipe. This terminated at a detachable nozzle at the pile

toe which could be easily changed between tests. Different

nozzles were used throughout the test program. Nozzles using

only a central orifice will be assessed in this paper. These were

modelled on small orifice plates, with a nozzle diameter of 0.5,

1.0, 2.5 and 3.0 mm.

Figure 2. Photograph of the model pile as used, with nozzle attached at

the toe and visible strain gauges at the pile head.

3.3 Water injection system

In order to model the water injection technique, a new system

was required to provide high pressure water to the pile at a

relatively high flow rate. Previous centrifuge testing of water

jetting used low flow rates and pressures, due to the chosen

pumping system.

Typical pumping systems for use one board a centrifuge

package are based on a syringe pump. Such systems are

commonly used for modelling excavations, where fluid is

drained from a region to simulate ground volume loss, or for

simulating pile jetting, such as the jetted spudcan experiments

of Gaudin et al. (2011). Syringe pumps are limited by the

actuator used to drive the piston. The actuator provides a high

degree of control over the flow, but also restricts its use to low

flow rate and low pressures. In addition, syringe pumps

typically have a small volume capacity, meaning it is difficult to

maintain high flow rates for a long period of time.

To avoid this issue during testing, the new system developed

derived water pressure from the radial acceleration down the

centrifuge arm. Water was provided to the slip rings at typical

mains pressure (around 200 kPa) and then fed to the package

through a pipe running down the beam. Moving through the

gravitational field gives an increase in pressure according to:

2

2 2

5.0

ring

slip

package

rings

slip

package

r

r

P

P

(1)

where P is the pressure at the package and slip rings

measured in Pascal, ω is the angular velocity of the centrifuge in

rad/s and r is the radius from the centre of the beam of the

package and slip rings in metres.

This procedure developed peak pressures at the model of 1.2

MPa and sustainable flow rates of up to 3.5 litres per minute.

Water pressure and flow rate were monitored at the centrifuge

model, a short distance from the pile toe. This location was

chosen for the simplicity of mounting a pressure transducer and

a turbine flow meter in the water delivery system. In addition, a

solenoid valve was used to allow or terminate flow to the pile.

Pressure at the pile toe could be calculated following the

centrifuge test using pipe flow theory as laid out by Goforth et

al. (1991). Loss factors can be confirmed by comparing

calculated values with data taken during a flow test – where the

pile toe is suspended above the sand surface and water is passed

through the system. The calculations can then be extended to

allow for different toe positions in the acceleration field and the

toe pressure at all pile depths can be found.

Flow rate control was achieved using a manually operated

flow tap before the slip rings. This controlled the water flow