964

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

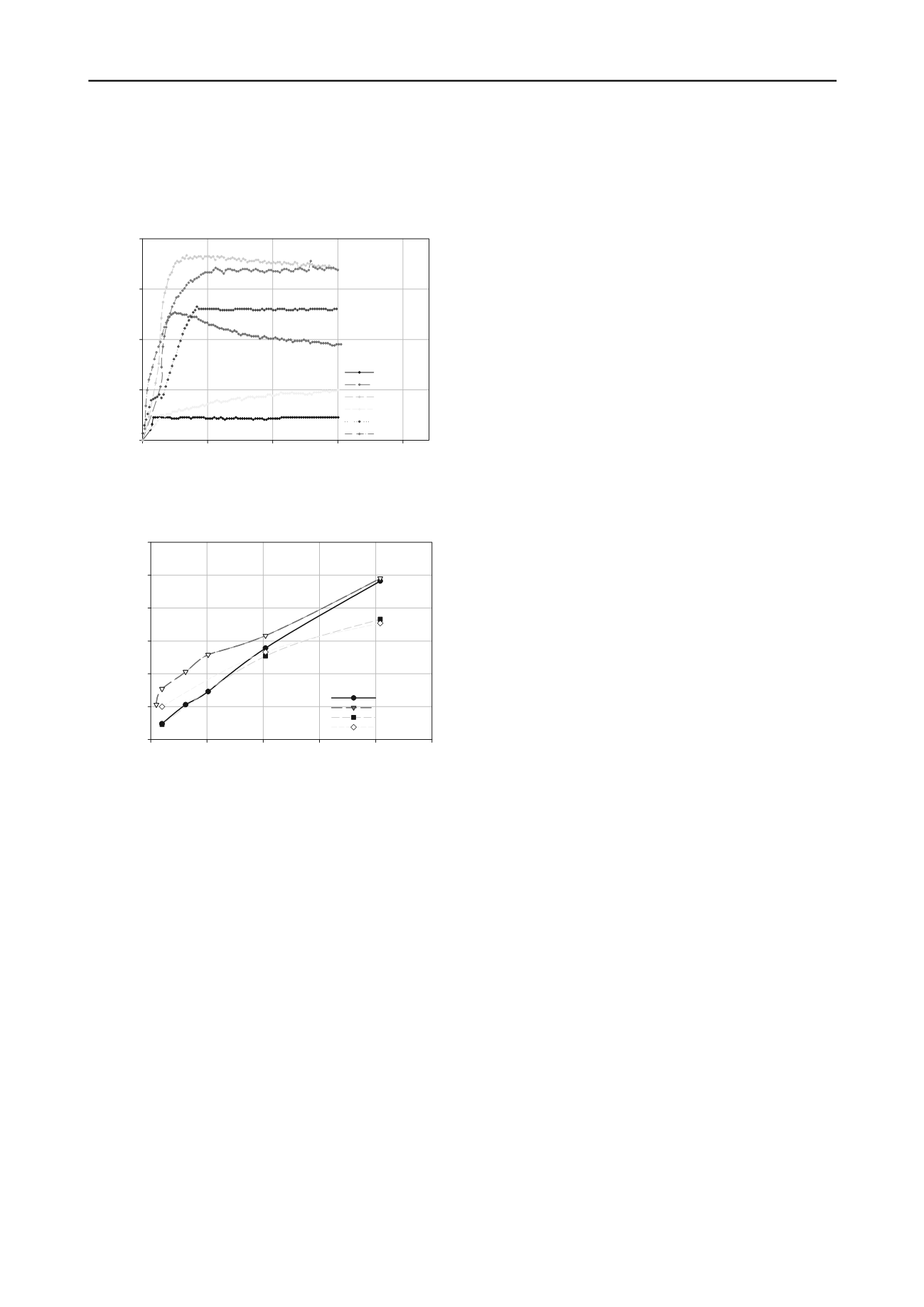

normal stress increased degradation of the asperities is

associated with decrease in increase of the shear strength and at

very high normal stress the complete shearing of the asperity

takes place and there is no effect of boundary conditions on

shear strength.

II. The % increase in shear strength

of unfilled joint

under

CNS

conditions as compared to CNL conditions is as

high as

221

for P

i

=0.10 MPa

.

Shear Displacement (mm)

0

5

10

15

20

Shear Stress (MPa)

0.0

0.5

1.0

1.5

2.0

CNL, P

i

=0.10

CNL, P

i

=1.02

CNL, P

i

=2.04

CNS, P

i

=0.10

CNS, P

i

=1.02

CNS, P

i

=2.04

MPa

CNL, k

n

=0 kN/m

CNS, k

n

=8 kN/m

m

m

i

III. The effect of the infill material in the joint is to reduce

the shear strength and a maximum reduction of 35% is

observed for 5mm infill thickness under CNS conditions

at P =0.10 MPa.

IV. The effect of boundary conditions on the shear strength

of non planar unfilled/ infilled rock joints decreases with

increase in P

i

, the effect is almost nil for P

i

≥0.18σ

c

.

5 REFRENCES

Shrivastava A.K. and Rao K.S. 2009. Shear behaviour of jointed rock:

a state of art.

IGC-Guntur

, 245-249.

Patton F.D. 1966. Multiple modes of shear failure in rock and related

materials.

PhD Thesis

, University of Illinois, Urbana.

Barton N 1973. Review of a new shear strength criterion for rock

joints.

Engineering Geology

7, 287–332.

Barton N. 1976. The shear strength of rock and rock joints.

Int. J.

Rock Mech. Min. Sci. and Geomech. Abst.

13, 255-279.

Yang Z.Y. and Chiang D.Y. 2000. An experimental study on the

progressive shear behaviour of rock joints with tooth-shaped

asperities.

Int. J. Rock Mech. Min. Sci.

37, 1247–1259.

Figure 4. Shear behaviour of 15

0

-15

0

infilled joint under CNL and CNS

boundary condition.

Obert L., Brady B.T. and Schmechel F.W. 1976. The effect of normal

stiffness on the shear resistance of rock.

Rock Mech

. 8, 57-72.

Ooi L.H. and Carter P.J. 1987. A constant normal stiffness direct shear

device for static and cyclic loading.

Geotechnical Testing Journal

10, 3-12.

Initial Normal Stress (MPa)

0.0

0.5

1.0

1.5

2.0

2.5

Peak Shear Stress (MPa)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

CNL unfill

CNS unfill

CNL infill

CNS infill

Johnston I.W., Lam T.S.K. and Williams A.F.1987. Constant normal

stiffness direct shear testing for socketed pile design in weak rock.

Geotechnique

37, 83-89.

Indraratna B., Haque A. and Aziz N. 1998. Laboratory modelling of

shear behaviour of soft joints under constant normal stiffness

condition.

J. Geotechnical and Geological Engineering

16, 17-44.

Gu X. F., Seidel J. P. and Haberfield C. M. 2003. Direct shear test of

sandstone- concrete joints.

Int. J. of Geomechanics

3, 21-33.

Kim D.Y., Chun B.S. and Yang J.S. 2006. Development of a direct

shear apparatus with rock joints and its verification tests.

Geotechnical Testing Journal

29, 1-9.

Kanji M.A. 1974. Unconventional laboratory tests for the

determination of the shear strength of soil-rock contacts,

Proc. 3

rd

Congr. Int. Soc. Rock Mech., Denver

2, 241-247.

ISRM 1977. Suggested method for determining water content,

porosity, density, absorption and related properties and swelling

and slake-durability index properties.

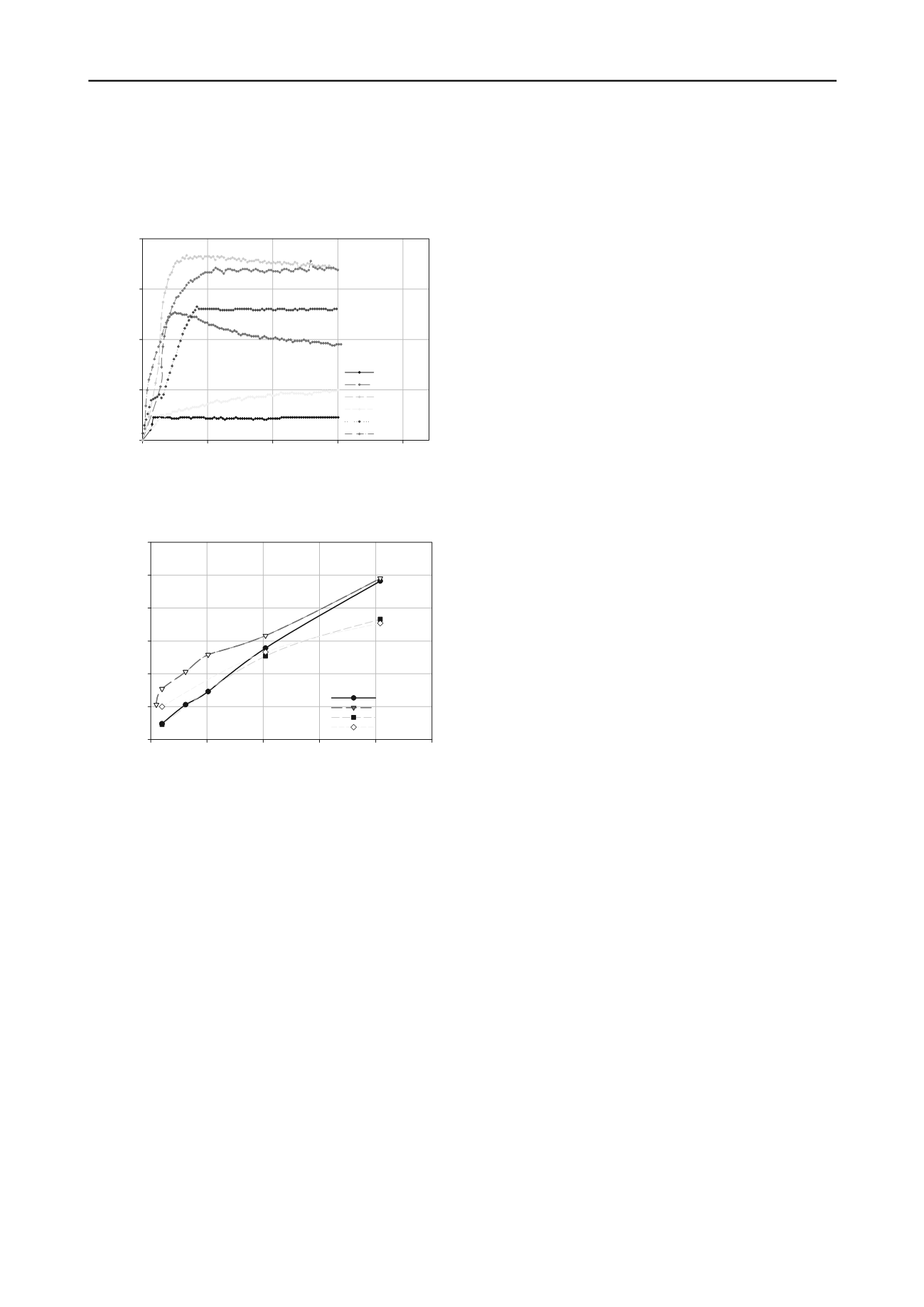

Figure 5. Strength envelope of 15

0

-15

0

unfilled and infilled joint under

CNL and CNS boundary condition.

ISRM 1979. Suggested method for determining the uniaxial

compressive strength and deformability of rock materials.

The increase in shear strength for unfilled joints for CNS

conditions varies from 221% to 6% of the CNL conditions

when P increases from 0.10 MPa to 2.04 MPa.

Deere D.U. and Miller R.P. 1966. Engineering classification and index

properties of rock,

Technical Report No. AFNL-TR-65-116

,

Albuquerque, N.M : Air Force Weapons Laboratory

.

i

The curvilinear strength envelope for infilled joint is

observed as presented in Fig.5 at all range of P

i

. But peak shear

stress of the infill joint is always less than that of unfilled joint.

Maximum reduction in shear strength of the infill joint as

compared to unfill joint for CNS condition is observed to be

35% at P

i

=0.01 MPa and % reduction in shear strength

decreases with increase in the P

i

. At high P

i

, the close look on

the sheared sample reflected breakage of the infill material,

which has resulted into more participation of the joints, hence

less reduction in shear strength.

Shrivastava A.K. 2012, Physical and Numerical Modelling of Shear

Behaviour of Jointed Rocks Under CNL and CNS Boundary

Conditions.

Ph.D. Thesis

, IIT Delhi.

Shrivastava A.K., Rao K.S. and Rathod, G.W. 2011. Shear

behaviour of infill joint under CNS boundary condition.

IGC - Cochi

, 981-984.

Rao, K.S., Shrivastava, A.K. and Singh Jattinder, 2009. Universal

large scale direct shear testing machine for rock.

INDOROCK- New

Delhi

, 157-168.

Shrivastava A.K. and Rao K.S. 2011. Shear behaviour of non

planar rock joints.

14

th

ARC on Soil Mechanics and

Geotechnical Engineering

, Hong Kong, China, 1-6.

4 CONCLUSIONS

The experimental studies on physically modeled unfilled and

infilled rock joints have been conducted to understand the effect

of boundary conditions and infill thickness on shear behavior.

The conclusions made from the test results are summarized

below:

I. CNL boundary condition is not suitable for non planar

rock joints and it under predict the shear strength, which

makes the design uneconomical.