955

Technical Committee 104 /

Comité technique 104

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The tank was filled with sand in multiple lifts. The height of

each lift was equal to the foundation width. The mass of soil for

each layer was determined from the required density. Soil was

poured through a funnel moving around the tank and to achieve

a uniform density, a specific height of fall was maintained. A

wooden float was used to compact and level the soil top after

every lift. The density achieved by compaction was checked by

putting square cans at various levels and reasonable accuracy

was observed. Water was supplied through rubber tubing

attached to a nozzle located at the bottom of the tank. Water

table was raised at a lift height of 100 mm (foundation width,

B

)

from the bottom of the tanks up to a depth of

B

below the

footing level. Then the rise was reduced to

B

/5 until the water

table reached footing level. The height of water table rise was

monitored by a glass tube attached to the soil tank. The load

was applied with a hydraulic jack. Settlement for each water

table lift was obtained by averaging the two dial gauge readings

placed on top of the footings. Figure 2 shows a close view of

the experimental setup used in the tests.

Rectangular Footing (

B/L

=0.25)

Rectangular Footing (

B/L

=0.5)

Square Footing (

B/L

=1.0)

Rectangular Footing (

B/L

=0.75)

Circular Footing

(a)

Square Footing (

B/L

=1.0)

Rectangular Footing (

B/L

=0.5)

Circular Footing

Figure 2. Experimental Setup with model footing, dial gauges and

loading arrangement.

Initially, pressure-settlement curves were obtained for each

case by applying vertical pressure in increments and measuring

corresponding settlements in dry condition. Then double tangent

method was used to determine bearing capacity of the footings.

This means the ultimate bearing capacity was taken as the

intersection of the two tangents drawn from the two linear

segments of the load-settlement plot. The working load was

taken as one-third of the bearing capacity, keeping the factor of

safety at 3. In the next step, the footings were subjected to

working loads and the water level was raised gradually from

bottom of the tank up to the footing level.

4 INTERPRETATION OF EXPERIMENTAL RESULTS

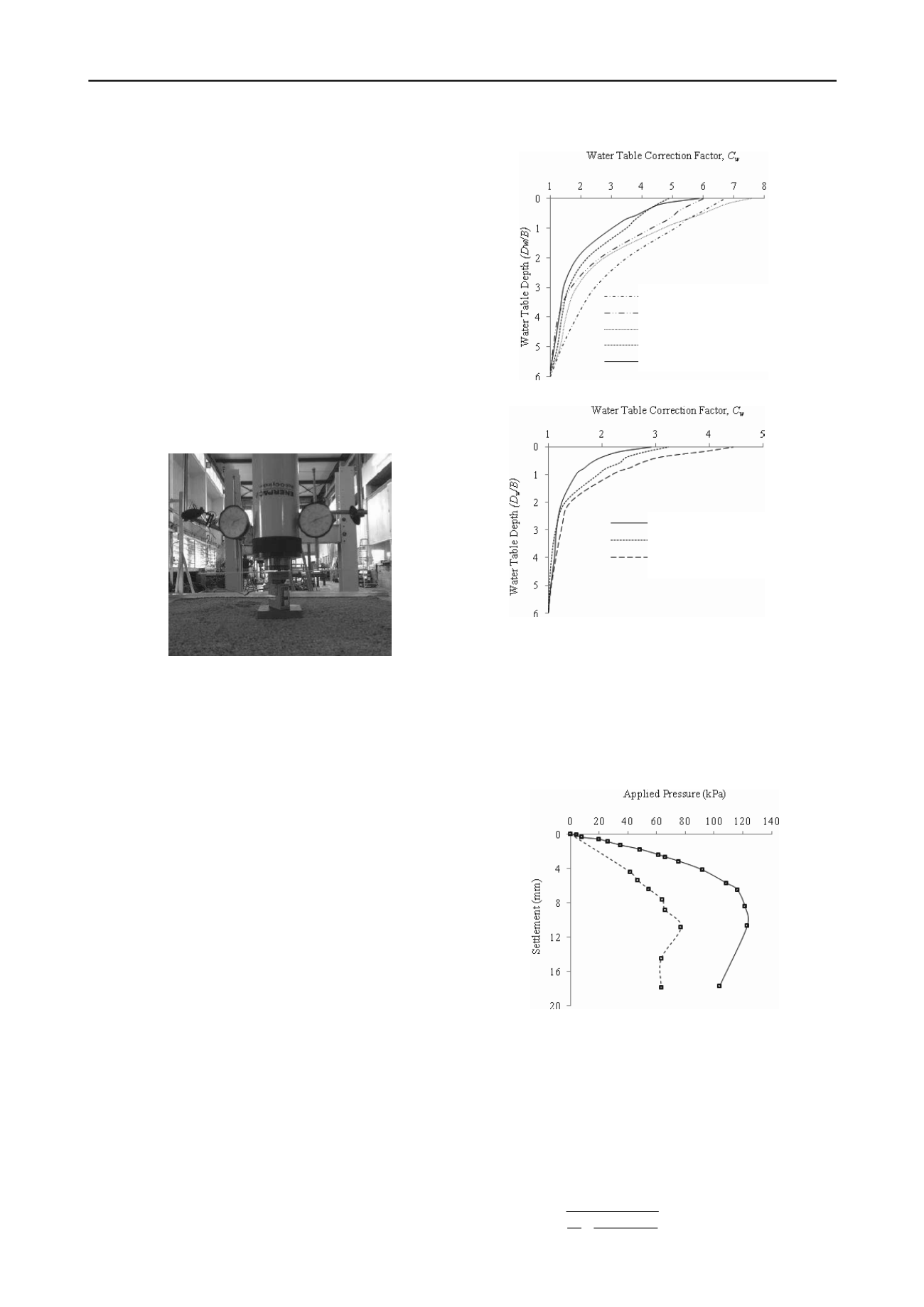

From the additional settlements measured at various water table

depths, the water table correction factor diagrams were

obtained. Figure 3 shows the correction factor diagrams for

various footing shapes in loose and dense condition. The figure

shows that the additional settlement due to water table rise is

higher in loose sands, with

C

w

ranging from 4.9 to 7.6 times the

settlement in dry condition. Footings on dense sand experienced

less additional settlements than in loose sands, with

C

w

ranging

from 2.9 to 4.4. The results indicate significantly higher

additional settlement due to rise in water table than what was

suggested by Terzaghi (1943).

It is evident from the curves in Figure 3 that the increment

in correction factor is not linear with water table rise, instead,

settlement increases at a faster rate when the water table gets

closer to the footing. The stress level immediately below the

footing is very high, which causes significant additional

settlements.

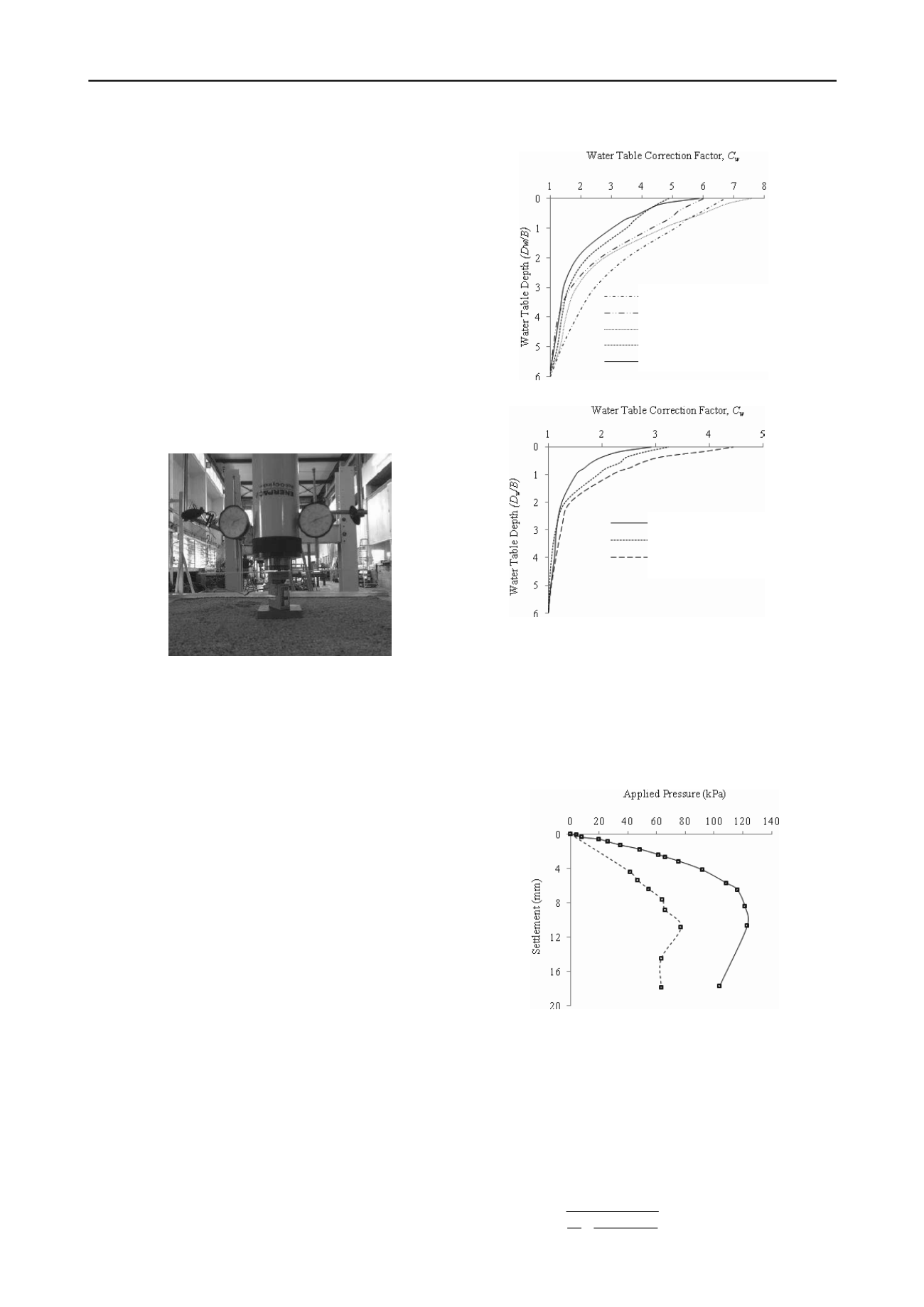

Figure 4 shows the load-settlement curves for square

footing resting on dense sand in dry (solid line) and submerged

Figure 3. Water table correction factor diagrams for model footings on

a) loose sand, b) dense sand.

(b)

condition (dotted line). It shows that the additional settlement in

submerged sand rises from 2.92 to 3.25 times as the applied

pressure rises from 40 kPa to 75 kPa. This reflects the effect of

stress level on additional settlement due to submergence. The

bearing capacity of soil gets reduced while submerged, which

induces high additional settlements at higher stresses.

Figure 4. Applied pressure-settlement curves for 100 mm square footing

in dry and submerged condition.

5 NUMERICAL MODELING OF EXPERIMENTAL

SETUP

The authors modeled the experimental setup in FLAC 6.0

(Itasca, 2008), a finite difference code used in geotechnical

modeling. A hyperbolic non-linear elastic model was used in the

simulation. The model relies on the nonlinear stress-strain

relationship suggested by Kondner and Zelaska (1963):

max 3

1

3

1

)

(

1

)

(

i

E

(2)