945

Technical Committee 104 /

Comité technique 104

laterally to a more rigid lateral/basal base by trajectories of the

major principal stress. Failure happened along the shear plane

generated by relative displacement. Because the undercut of a

steep slope generates more stress relief, the shear zone is bigger

with a wider shape at the top. While the shear zone of a mild

slope is smaller with a wider shape at the bottom. This

difference causes many failures of arches. Subsequent stacks of

arches can form in a mild slope until reaching the collapse of a

whole slope, while failure will happen aggressively for a steep

slope due to slope buckling without many local failures.

Characterization of each type of failure is different by means

of arching coefficients,

k

, based on theoretical mechanics and

validated by the results of the physical model test. Three values

of the coefficient are provided for (1) a strip arch with soil slip,

(2) a segmented arch with stable scarp and (3) a circular arch

with slope buckling. For a slope with no arching, the arching

coefficient is merely zero.

5 APPLICATIONS TO SITE CONDITIONS

Since bedding shear zone in the clay seam layer is considerably

thin, excessive pore water pressure can be dissipated in a short

time. The drained shear strength obtained from a constant-

volume direct shear test with measurement of vertical stress

change is considered applicable to the site condition (Ohta et al.

2010). Wangsa et al. (2012) and Pipatpongsa et al. (2011)

examined the mechanical properties of G1 green clay which is

associated with a bedding shear zone in Area 4.1. The residual

friction angles with zero cohesion-intercept obtained from

multi-stage reversal constant volume direct shear box test are

ranged from 12 to 17. Therefore, the minimum value of 12

was considered as a critical case. Moreover, consideration of

hydro-static pressure is required in engineering practice. Four

cases are considered below.

A) Failure width of passive arching slope in dry condition

sin tan cos

c

f

i

k

B

(3)

B) Failure width of passive arching slope in dry condition

with hydro-static pressure on bedding shear plane

sin 1

tan cos

c

f

w

i

k

B

(4)

C) Failure width of passive arching slope in fully saturated

condition with no hydro-static pressure on bedding shear

plane

1

sin tan cos

c

f

w

i

k

B

(5)

D) Failure width of passive arching slope in fully saturated

condition with hydro-static pressure on bedding shear

plane

1

sin 1

tan cos

c

f

w

w

i

k

B

(6)

As the last condition is the most critical case, Eq.(6) is

employed to determine the failure width in the implementation

at the site. Based on various laboratory and field experiments,

the material parameters (EGAT 1985, 1990, Khosravi et al.

2011 and Wangsa et al. 2012) are selected for the analysis as

summarized in Table 1. The contribution of the arching effect

can be evaluated by a factor of safety. The safety factor for a

two-dimensional slope (planar condition) is simply calculated

by Eq.(7) and Eq.(8) for dry and submerged conditions,

respectively. Based on Eq.(3) and Eq.(6), the factor of safety for

three-dimensional slopes (arching effect condition) can be

calculated by Eq.(9) and Eq.(10) for dry and submerged

conditions, respectively.

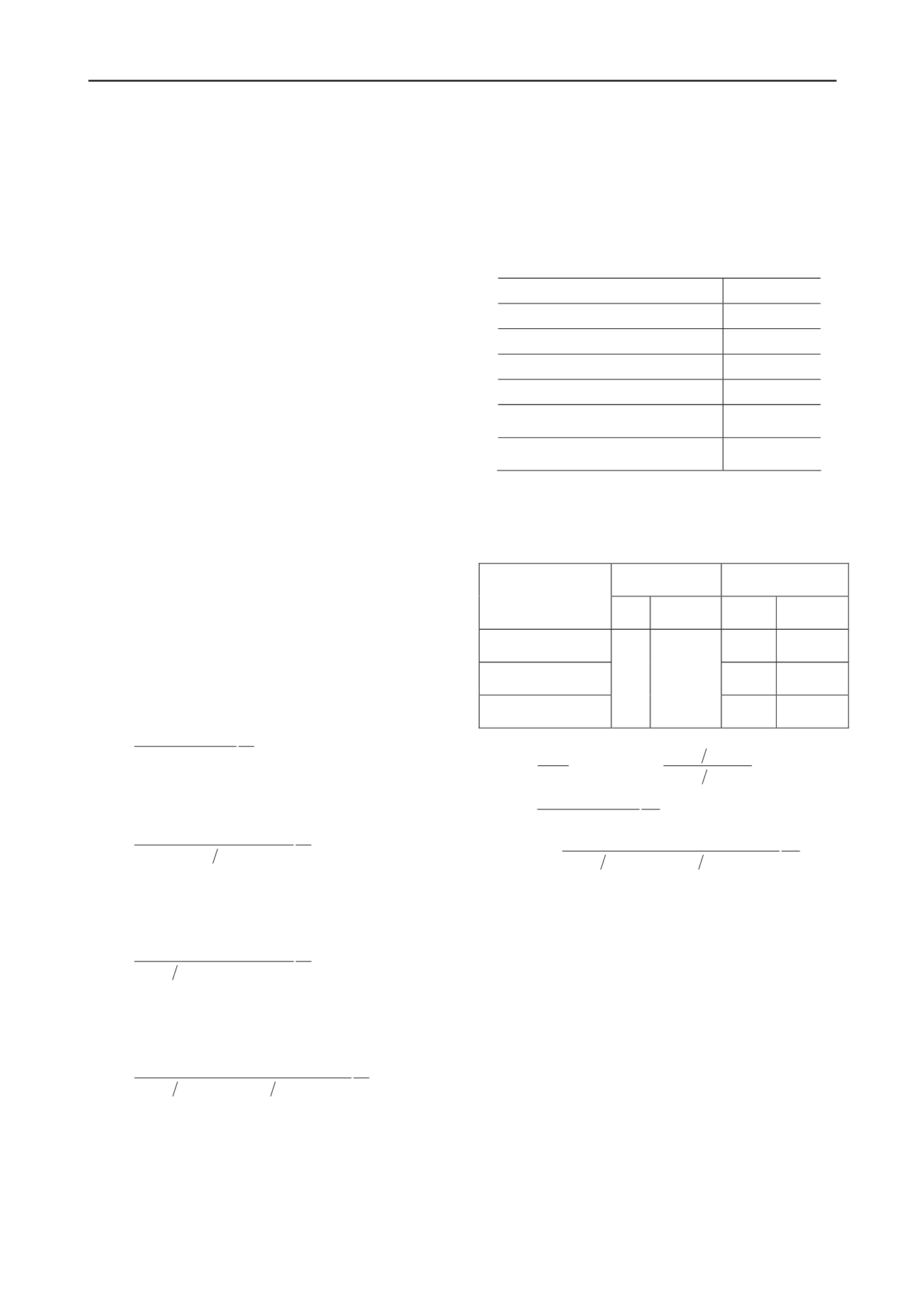

Table 1. Geometry and material parameters of the green clay seam and

hale required for calculating safety factor of the undercut slope.

s

Inclined slope,

18

o

Residual interface friction angle,

i

12

o

Bulk unit weight of shale,

19.12 kN/m

3

Unit weight of water,

w

9.81 kN/m

3

Residual UCS of shale,

cr

0.33 MPa

Peak UCS of shale,

cp

4.50 MPa

Designed UCS of shale,

cd

1 MPa

UCS =

unconfined compressive strength

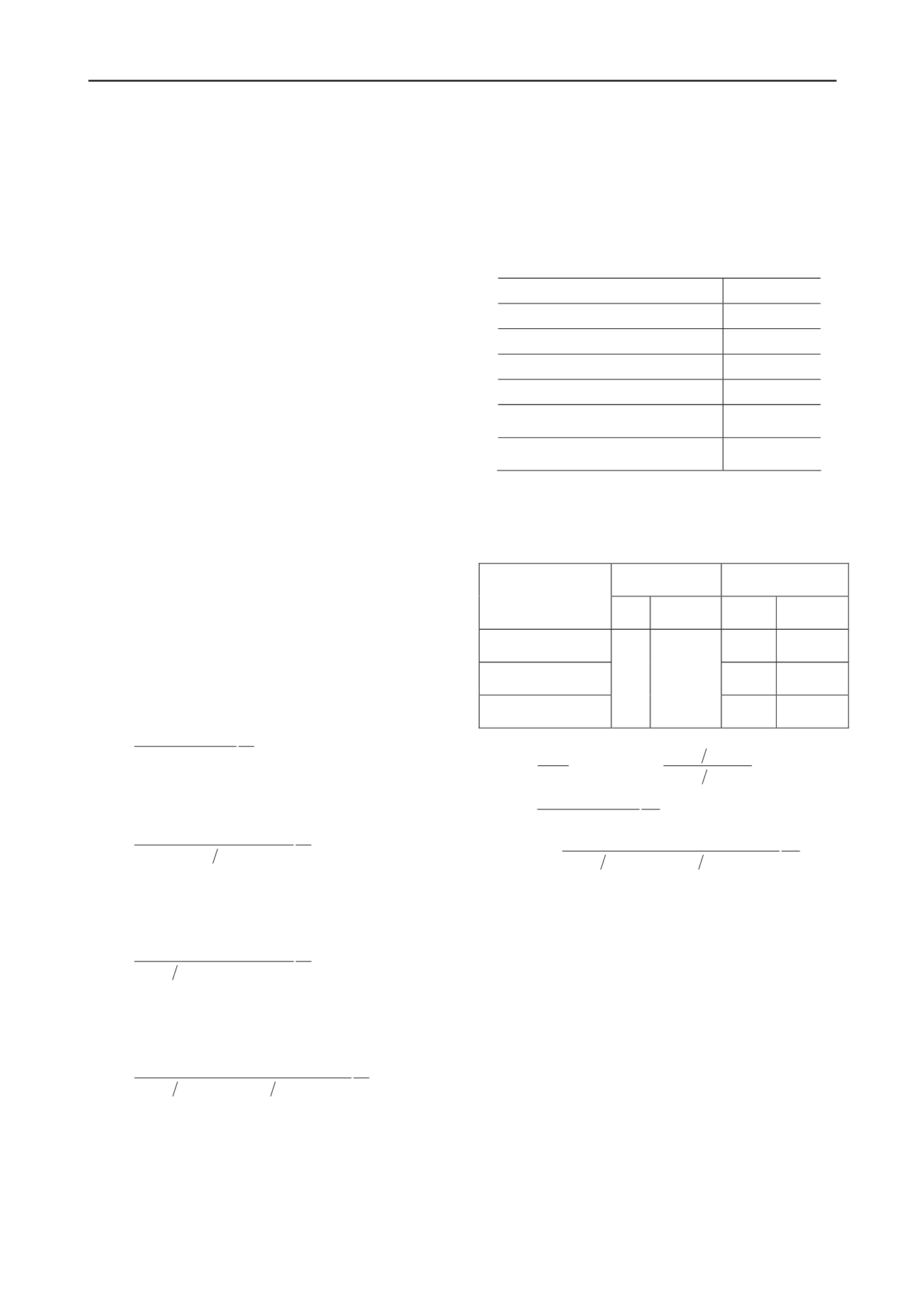

Table 2. Calculated safety factors against a width 130 m for dry and

submerged conditions under two and three dimensions using residual,

peak and designed values of unconfined compressive strength of shale

ith an arching coefficient assigned to

k

2

=1.

w

2D

(planar

slope)

3D

(arching

effect)

Safety factor

d

ry

subme

rged

dry

submer

ged

Residual

rock

strength

1.2

0.4

Peak

rock

strength

16.

9

4.9

Designed

rock

strength

0

.6

0.2

3.8

1.1

2 ,

tan

tan

i

D dry

SF

,

2 ,

1

tan

1

tan

w

D submerged

w

SF

i

(7), (8)

3 ,

sin tan cos

c

D dry

i

k

SF

B

(9)

3 ,

1

sin 1

tan cos

c

D submerged

w

w

i

k

SF

B

(10)

Using the material parameters shown in Table 1, the safety

factor determined from Eqs.(7)

(10) are shown in Table 2. In

the calculation, the arching coefficient assigned to

k

2

=1 for mild

slopes with supporting ground for the maximum exposed width

130 m. Safety factors based on a planar condition for both dry

and submerged conditions are less than one which might

conclude that the slope cannot be undercut. However, an

arching effect allows a higher factor of safety; therefore, if the

shale above the clay seam has not been weathered into weak

soft rock, mining at Area 4.1 with the span of 130 m is possible.

The undercut span at Area 4.1 is varied as a function of the

unconfined compressive strength of the shale; thus, if the

unconfined compressive strength of shale on the slope could be

maintained at 1 MPa at the least, the undercut span of 130 m at

the clay seam level can be reached safely in a short term.

The width of Area 4.1 in the Mae Moh lignite mine is about

300 m and the length about 250 m along the pit wall. The total

depth of 33 m in this area for lignite mining was planned by

digging 3 benches with a height of 11 m each. According to

EGAT’s mining plan, Area 4.1 is divided into 2 stages of

excavation, namely stage 1 for 180 m and stage 2 for 120 m