940

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 EXPERIMENTAL PROGRAM

In total, 12 isotropically consolidated drained (CD) triaxial tests

were performed on consolidated kaolin specimens having a

diameter of 7.1 cm and a length of 14.2 cm. Tests were

conducted on control specimens and specimens that were

reinforced with single sand columns having diameters of 2cm,

3cm, and 4cm with a column penetration ratio H

c

/H

s

of 0.75.

The 2-cm, 3-cm, and 4cm diameter columns represent area

replacement ratios A

c

/A

s

of 7.9%, 17.8%, and 31.5%

respectively. All sand columns were placed in pre-drilled holes

in the center of the clay specimens. All specimens were

saturated using a back pressure of 310 kPa and isotropically

consolidated under effective confining pressures of 100, 150, or

200 kPa. In all tested specimens, the measured “B” value was

greater than 0.96 indicating an adequate degree of saturation.

Samples were then sheared in drained conditions at a strain rate

of 0.25% per hour (~0.06mm/min). All tests were terminated at

a maximum axial strain of about 12%.

2.1. Material Properties

The clay used in the testing program is a kaolin clay with a

liquid limit of 55.7%, a plasticity index of 22.4%, and a specific

gravity of 2.53. Consolidation and strength properties for the

clay are presented in Najjar et al. (2010). Ottawa sand which

classifies as poorly graded sand (SP) according to the Unified

Soil Classification System was used to construct the sand

columns. For sand specimens prepared at a dry density of 16.2

kN/m

3

(relative density of 44%), Najjar et al. (2010) reported an

effective peak friction angle of 33

o

based on consolidated

undrained triaxial tests with pore pressure measurement. In this

study, isotropically consolidated drained triaxial tests were

conducted on sand specimens with a height of 14.2 cm and a

diameter of 7.1 cm at confining pressures of 100, 150, and 200

kPa to determine the friction angle of the sand. The resulting

effective friction angle was found to be equal to 35

o

. The

difference between the measured effective friction angles from

the CU+U and CD tests could be attributed to the respective

mean effective stresses at failure which were an order of

magnitude greater for the undrained tests.

2.2. Sample Preparation

Kaolin clay powder was mixed with water at a water content of

100% (i.e. 1.8 times its liquid limit) to form a slurry. The slurry

was then poured into custom-fabricated consolidometers in

preparation for one-dimensional consolidation. Dead weights

were used to consolidate the specimens from slurry to a vertical

effective stress of 100 kPa. The water content at the end of the

consolidation stage was relatively uniform (~53%) throughout

the depth of the sample. The average bulk density for all the

clay specimens prepared was about 16 kN/m

3

. A detailed

description of the sample preparation and testing procedure is

presented in Najjar et al. (2010).

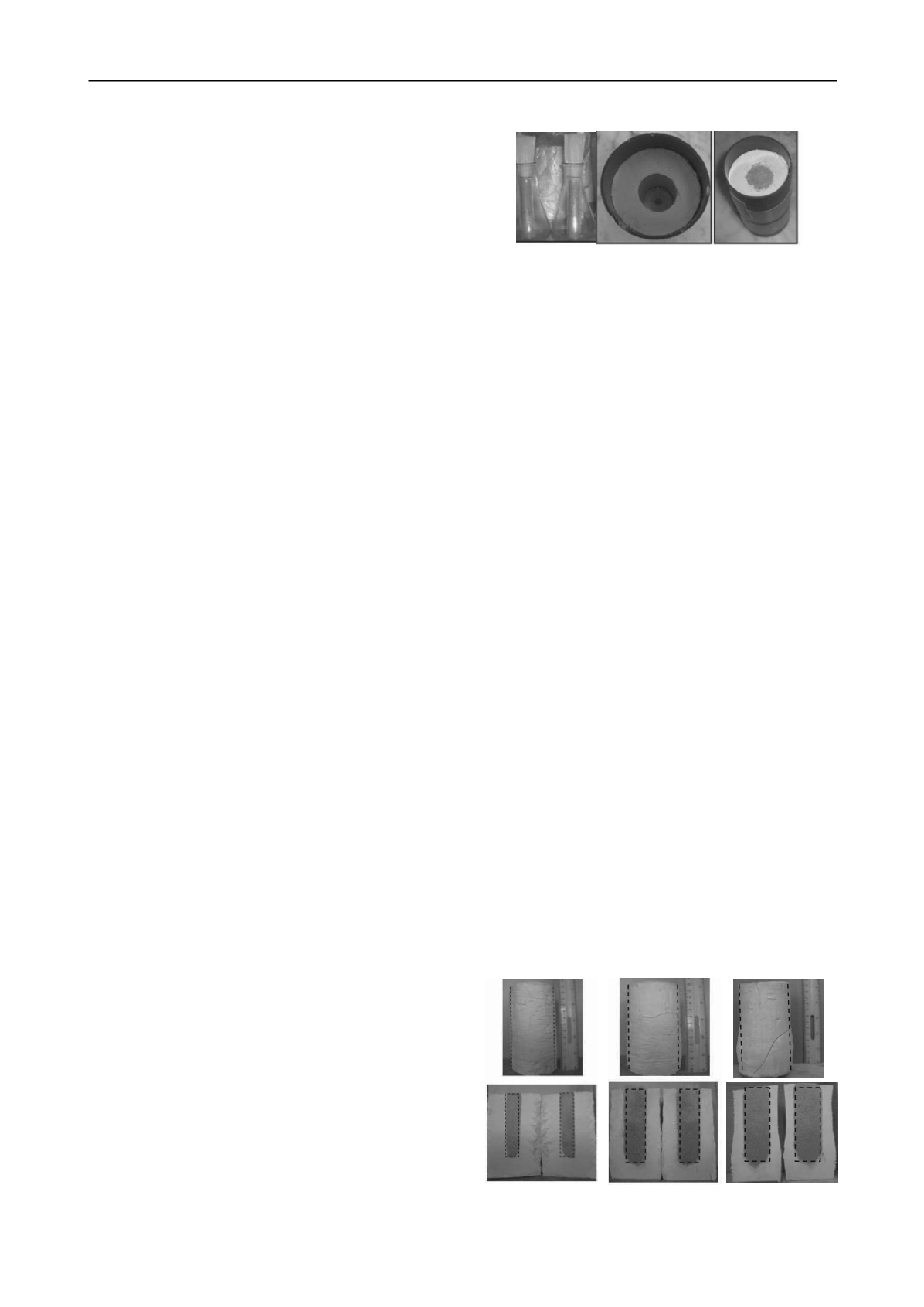

The sand columns were formed from Ottawa sand at a dry

density of about 16.2 kN/m

3

. These sand columns were

prepared by pouring 3 layers of dry Ottawa sand in cylindrical

pre-cut and stitched geosynthetic fabrics. The fabrics were

initially inserted in a glass tube having the same inner diameter

as the sand column, and the sand layers were densified by

vibration. Water was then added to the sand column to reach a

water content of about 20%. The saturated sand column was

then frozen for 24 hours (Fig. 1a). The geosynthetic fabric was

cut and detached from the sand column. The frozen sand

column was then inserted into a hole drilled at the center of the

clay specimen (Fig. 1b) and allowed to thaw. The reinforced

clay specimen (Fig. 1c) was then transferred to the triaxial cell

and saturated using a back pressure of 310 kPa.

Figure 1. Installation process of sand columns.

3 TEST RESULTS AND ANALYSIS

The automated triaxial test setup “TruePath” by Geotac was

used to conduct CD tests on control and reinforced clay

specimens saturated at a back pressure of 310 kPa. The samples

were then isotropically consolidated under confining pressures

of 100, 150, or 200 kPa and sheared drained at a strain rate of

0.25% per hour, while measuring volume change through drain

lines connected to the porous stones at the top and bottom of the

sample. The measured volume change reflects a global change

in the composite sample and do not provide information on

local changes in the water content in the sand column and the

surrounding clay. Throughout the tests, the total confining

pressure was kept constant as the vertical stress was increased in

compression.

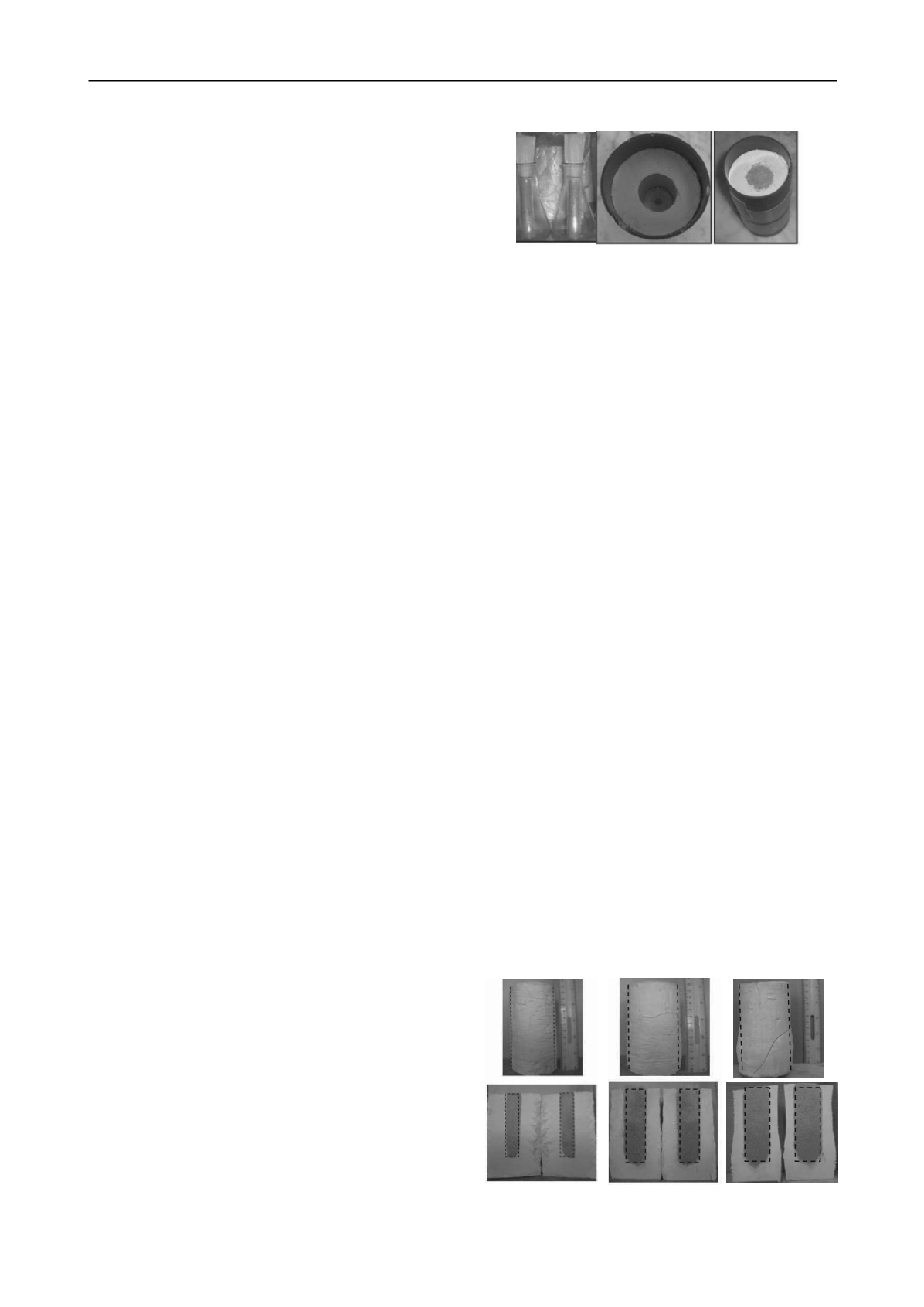

3.1. Mode of Failure

The mode of failure was characterized by bulging of the clay

specimen. The bulging was slight and relatively uniform along

the height in samples reinforced with the smallest area

replacement ratio of 7.9% (see Fig. 2a). As the area replacement

ratio increased, the bulging was significant and concentrated in

the lower half of the clay specimen, indicating stress and strain

concentration in the unreinforced portion of the specimen. For

the largest area replacement ratio of 31.2%, clearly defined

shear planes formed in the lower half of the sample as indicated

in Fig. 2c.

To investigate the mode of failure of the sand columns, the

same test specimens were split along their vertical axes to

expose the columns and the surrounding clay (Figs. 2a-2c). The

figures indicate that relatively uniform bulging of the sand

columns occurred with depth, with the specimens at the higher

area replacement ratios showing signs of punching of the sand

columns into the unreinforced clay.

3.2. Stress-Strain Response

The variation of the deviatoric stress and volumetric strain with

axial strain is presented in Figs. 3, 4, and 5 for tests with

replacement ratios of 7.9, 17.8, and 31.2%, respectively. The

stress-strain curves exhibited consistent increases in deviatoric

stresses with strains as the samples were sheared towards

critical state conditions. In this paper, failure is defined at an

axial strain of 12%, which is the maximum strain measured.

(a) A

c

/A

s

= 7.9% (b) A

c

/A

s

= 17.8% (c) A

c

/A

s

= 31.2%

Figure 2. Internal and external modes of failure.