932

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

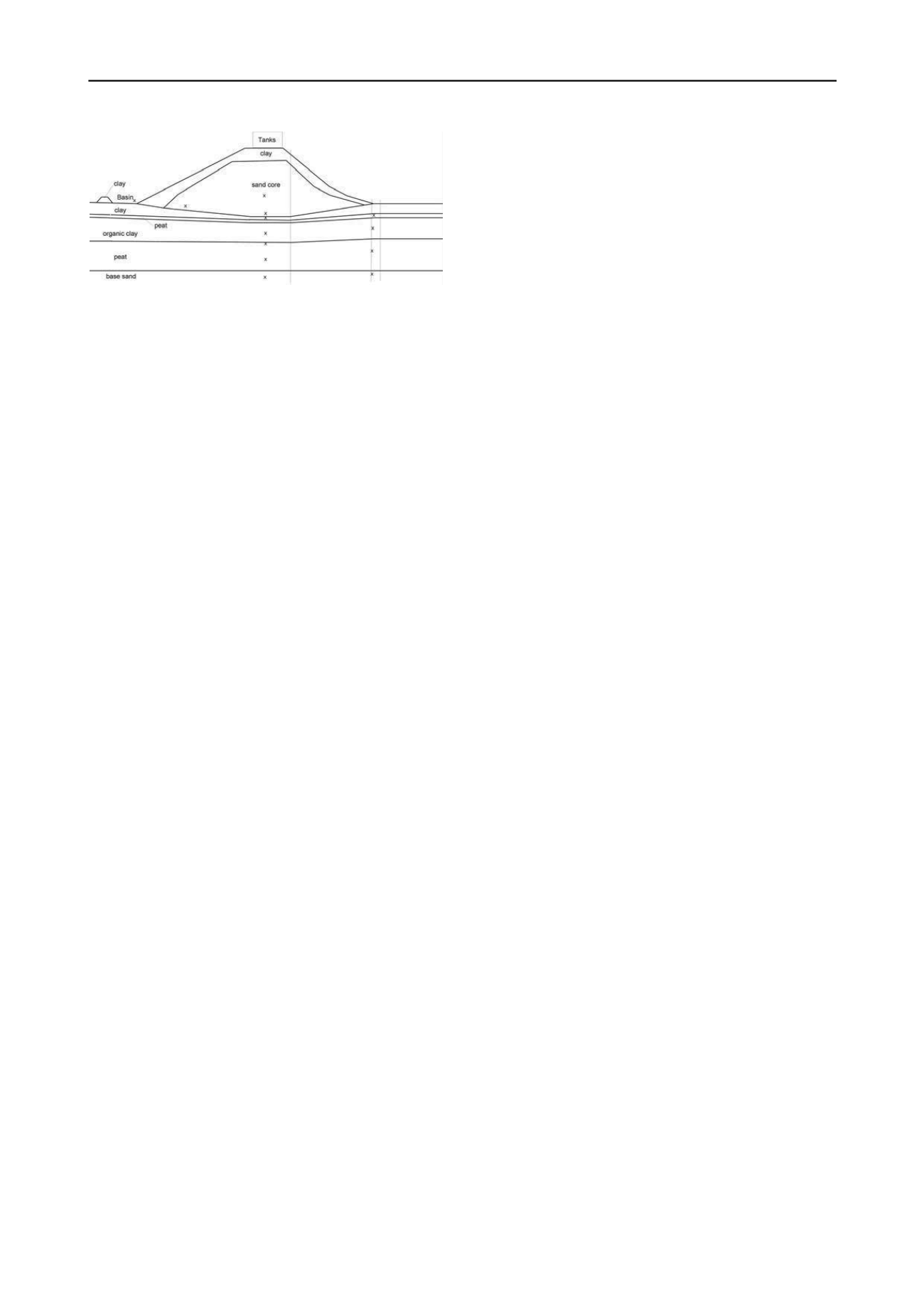

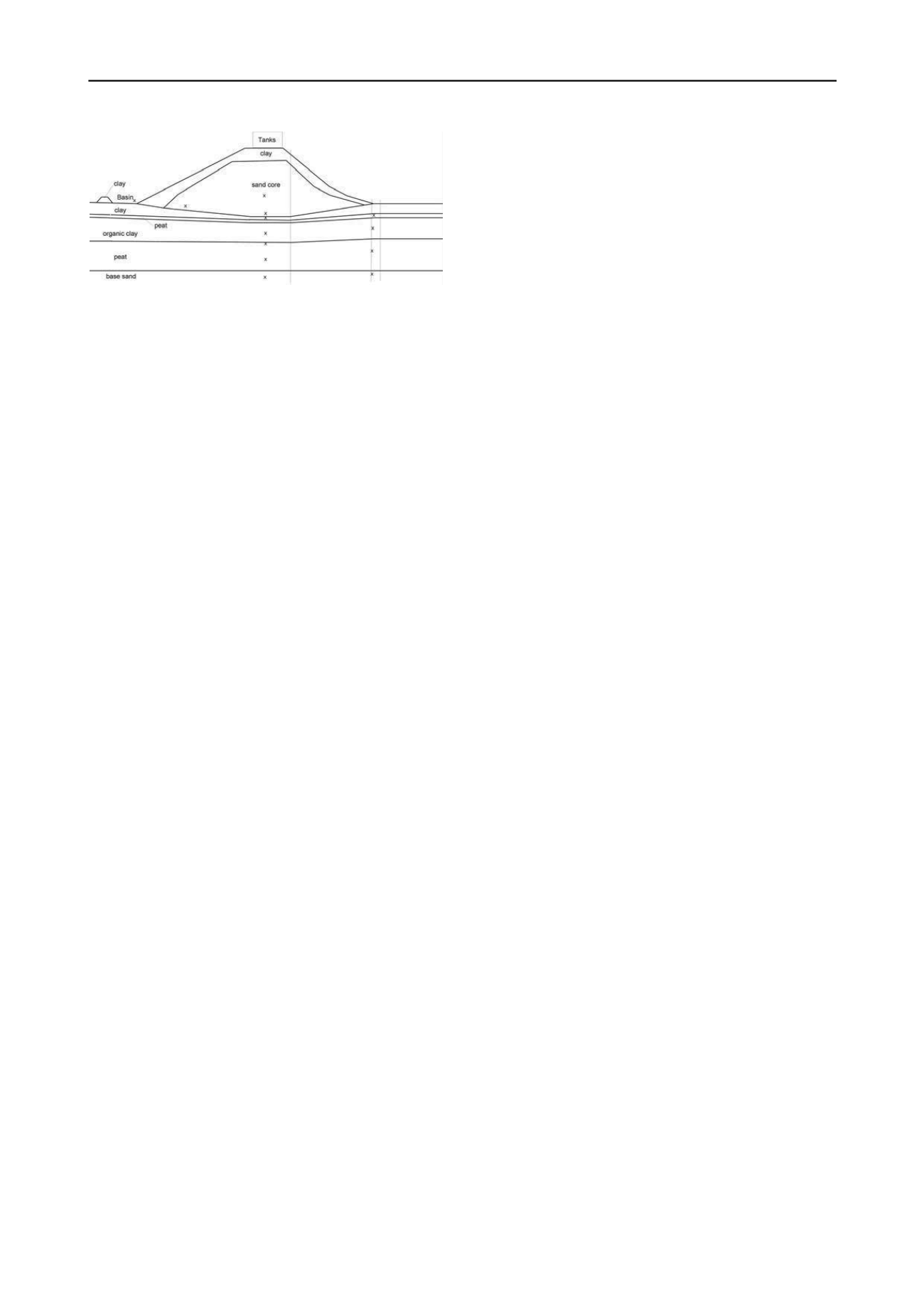

Figure 2. Cross-section of South dike at start of test, showing settled

geometry and indicating positions of reference monitoring.

and subsequent erosion of the downstream slope. The earlier

tests on piping had a similar configuration, but with a more

sound clay dike (van Beek et al 2011). Those tests failed to

piping at reservoir levels ranging from 1.75m to 2.3m. In order

to make piping less likely this time, in each test dike a piping

prevention measure has been placed. In the West dike, piping is

controlled by a controllable drainage tube at 3.7m from the

downstream toe, while in the East dike a coarse sand filter has

been placed as a rectangular box 0.5m wide, 0.5m deep around

3.5m from the downstream toe. The grain size of this filter

varies from 1 to 2 mm, the grain size distribution is such that

excessive loss of particles through this filter is prevented

(Burenkova 1993).

2.2

South dike

The South dike was built on a 4.5m thick composition of soft

peat and clay. After construction, it was 4m high, 50m long at

crest level, with a crest width of 3m and side slopes of 1:1.5

(V:H). The core was made of sand, with a 0.5m thick clay layer.

Figure 2 shows a cross-section of the dike at the start of the test,

i.e. after consolidation resulting in a settlement of 0.99m.

The designed failure modes of this dike were slope stability

with a deep sliding plane through the subsoil with a minimum

deformation of 20cm and rupture of the clay cover by high pore

pressures inside the sand core as a result of saturating this core

with water.

3 INSTRUMENTATION

For the instrumentation a clear distinction is made between the

reference monitoring and the instruments of the participating

companies. The reference monitoring was required (and

sufficient) to closely monitor the course of the tests, while the

other instruments were validated and the measurements were

used to make updated predictions of the failures.

A total of nine companies participated with their instruments

– some in all tests, others in only one or two. Each of these

companies were invited to use their own measurements to give

an initial prediction of the failure mode and the conditions at

which failure would occur, and to update this prediction at least

every 24 hours.

Three companies providing dike safety information systems

participated in all three tests. These companies had access to the

data of the monitoring systems being validated through a central

data base. The data of the reference monitoring was not

disclosed during the tests.

3.1

West dike

The reference monitoring was primarily carried out with pore

pressure meters: two to record the water levels in the upstream

and downstream reservoirs, four lines of 17 meters each at the

interface between the lower sand and the well-compacted clay

layer at 0.9m, 2.5m, 4.3m and 11.2m from the downstream toe

and a 3 by 3 grid of pore pressure meters at the bottom of the

sand core: right behind the small clay dike and at 1.8m and

6.0m downstream, respectively. In addition, visual inspections

were carried out at regular intervals, an HD camera facing the

downstream slope taking one frame every five seconds was

used, rainfall data was recorded and the upstream and

downstream discharges were measured.

The following instrumentation was installed by the seven

companies participating in this test:

- glass fibre optics woven into geotextile, measuring

temperature and strain approximately every metre in eight lines

parallel to the toe of the dike, five at the sand/clay interface and

three in the downstream slope;

- a Fast Ground Based Synthetic Aperture Radar system,

measuring a two-dimensional displacement field of the

downstream slope every five seconds;

- two vertical tubes, installed at the upstream crest line,

measuring temperature and strain profiles over depth employing

glass fibre optics;

- a thermic infrared camera facing the downstream slope,

with a resolution of 640x480 pixels and an accuracy of 0.05 K;

- a ground penetrating radar system at 100 MHz, operated by

moving it across the crest of the dike;

- two controllable drainage tubes with measurements of pore

pressure, temperature and discharge, located close to the

sand/clay interface at 3.7m from the downstream toe (lower

tube) and right behind the small clay dike at the bottom of the

sand core (upper tube);

- six pore pressure meters at the sand/clay interface, three at

0.5m from the downstream toe and three at 2.2m.

3.2

East dike

The reference monitoring at the East dike was almost identical

to the West dike, but with four lines of 16 instead of 17 pore

pressure meters at the sand/clay interface.

The six companies participating in this test installed the

following:

- glass fibre optics woven into geotextile, measuring

temperature and strain approximately every metre in eight lines

parallel to the toe of the dike, five at the sand/clay interface and

three in the downstream slope;

- two vertical tubes, installed at the upstream crest line,

measuring temperature and strain profiles over depth employing

glass fibre optics;

- an electric resistivity system employing two rows of 14

electrodes on the downstream slope;

- a thermic infrared camera facing the downstream slope,

with a resolution of 640x480 pixels and an accuracy of 0.05 K;

- a ground penetrating radar system at 100 MHz, operated by

moving it across the crest of the dike;

- ten pore pressure meters at the sand/clay interface, five at

0.7m from the downstream toe and five at 2.2m.

3.3

South dike

The reference monitoring at the South dike consisted of 34 pore

pressure meters and six automatic inclinometers. Twentysix

pore pressure meters were installed in two cross-sections each

13m from the centre line, as indicated in Figure 2, six pore

pressure meters were installed in six water tanks on top of the

crest and the remaining two were installed in the basin on the

non-failing side of the dike and in the ditch which was

excavated during the test to reduce the overall stability. The

inclinometers were distributed along the centre line and both

instrumented cross-sections.

The seven companies participating in this test installed the

following:

- glass fibre optics woven into geotextile, measuring

temperature and strain approximately every metre in three

parallel lines along the whole length of the dike, on ground level

and on two higher levels;

- a system of six extremely accurate inclination instruments,

each mounted on top of a 5.6m steel rod placed on the slope of

the dike (three on the side of the failure, three on the other side);