944

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

According to the full core drilling, which consists of up to 900

holes have been drilled in the Mae Moh mine during the period

1987

2005. The thickness of the bedding shear zone ranges

from 10 to 80 mm. About 40% of the bedding shear zone

comprises continuous layers of clay seam. In this study, the

targeted area is Area 4.1, shown in Fig.1. Its cross-section is

shown in Fig.2.

Potential failure plane

(Shearing zone, green clay)

Lignite layer

Unstable rock mass

Borehole NEI N29

(Depth: 50m)

A

A’

Figure 2. Cross-section A-A’ of Area 4.1 (Courtesy of EGAT)

Blockof moist Silica

sand No. 6

Position of block

before slippage

α

f

Figure 3. Slippage of the sand block along the lateral supports (after

Khosravi et al. 2012)

Side supports

Side supports

α

=40

o

T

=0.05m

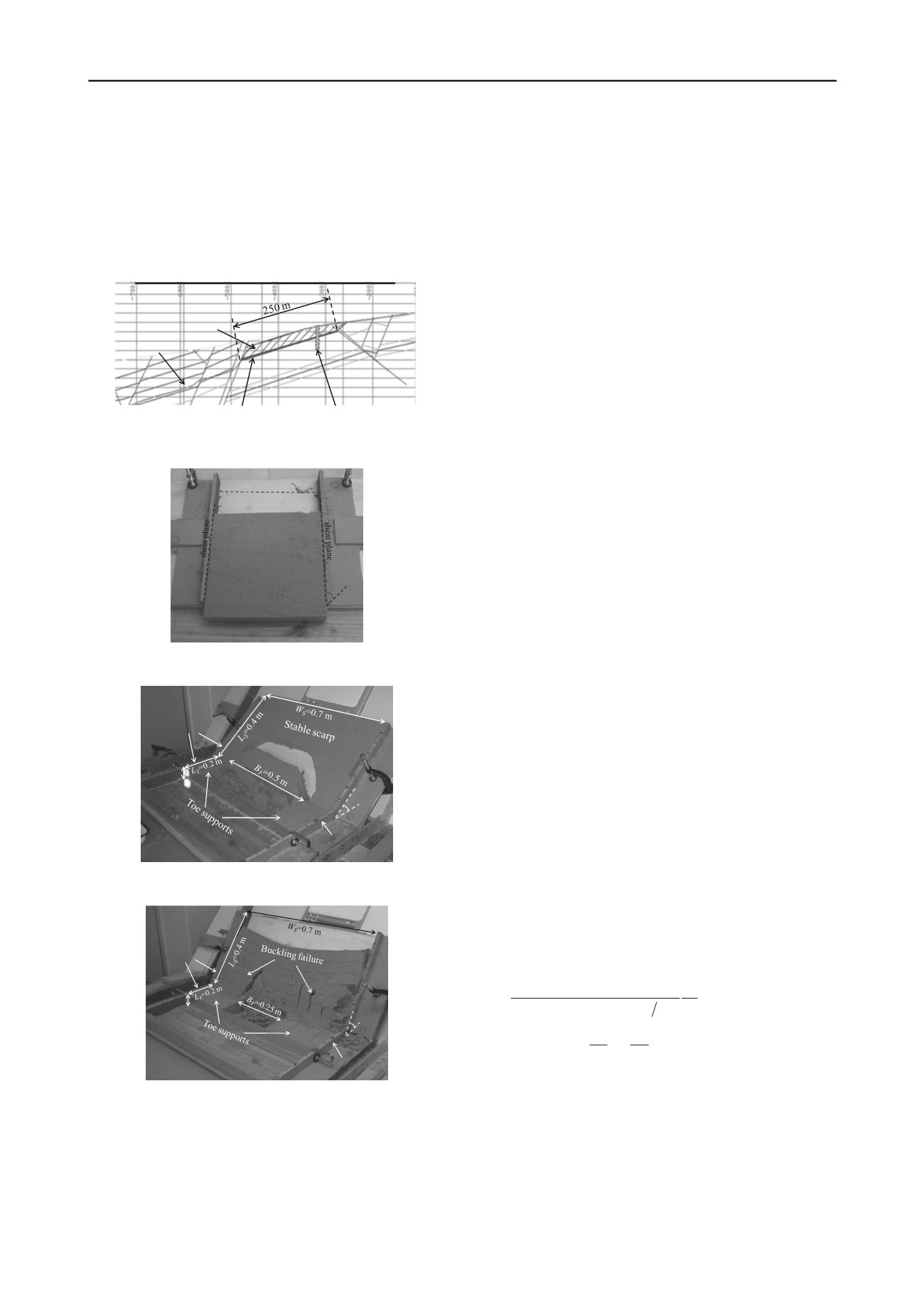

Figure 4 Arch-shaped failure in mild undercut slopes at the maximum

undercut span (after Khosravi et al. 2012)

Side supports

Side supports

α

=60

o

T

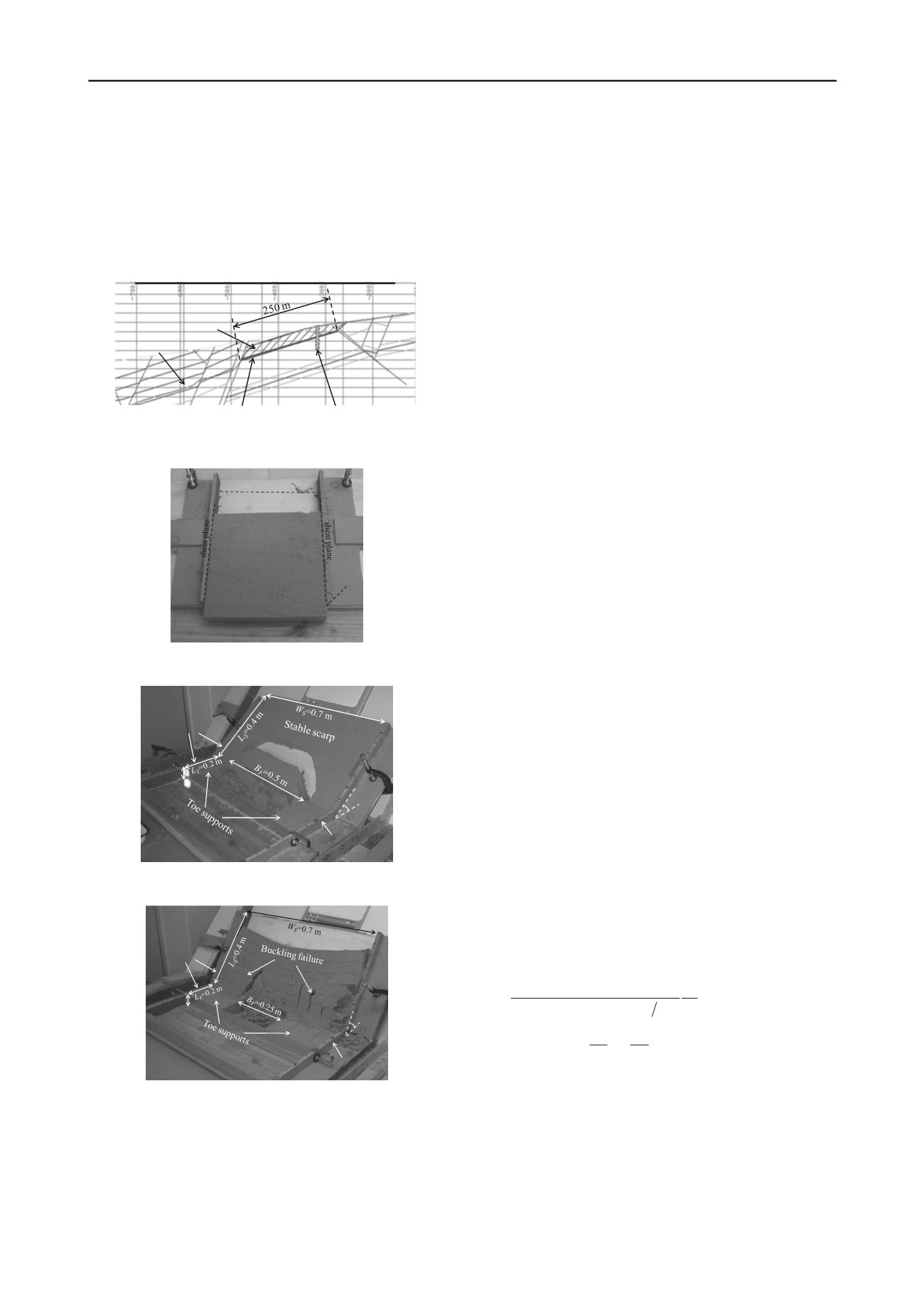

=0.05m

Figure 5. Buckling failure in steep undercut slopes at the maximum

undercut span (after Khosravi et al. 2012)

3 PHYSICAL MODEL

Khosravi et al. (2009, 2010, 2011) have conducted a series of

simple experiments using a block of compacted moist sand

confined by parallel rigid walls by varying thickness, width and

length. The inclined angle of the bedding plane was gradually

increased until the block started to slip (see Fig.3). Also, some

laboratory-scale undercut slope physical model tests were

conducted under both 1G and centrifugal acceleration fields.

The existence of passive arching effects in the slope models can

be confirmed by means of earth pressure recordings and image

processing techniques. In the undercut slopes, some parts of the

load are transferred from the yielding portion of the slopes to

the stiffer sides. The level of load transfer depends on the

stiffness and strength of the lateral supports. Two types of slope

failures can be expected: an arch-shaped failure (see Fig.4) in

the central part of the slope for the strong sides, and side

buckling (see Fig.5) leading to total failure of the slopes for the

weak sides. In addition, the performance of a counterweight

balance, which is considered a technique to stabilize undercut

slopes with weak sides, was demonstrated through a series of

physical models and confirmed that a wider undercut span in

front of the slope can be realized (Khosravi et al. 2012).

4 THEORETICAL BACKGROUND

In chemical engineering, a stable arch formed across the orifice

of a hopper causes difficulty in discharging of cohesive

material; therefore, determination of the minimum diameter

which destabilizes the arch action is required. On the other

hand, in mining engineering, a stable arch formed across a pit is

beneficial to the design of an undercut slope; therefore,

prediction of the maximum undercut width which does not

cause it to collapse is needed. Jenike’s (1961) model for arch

formation has laid the foundation for understanding the

behavior of a static system of cohesive materials confined by

hopper walls (Walker 1966 and Walters 1973). This study

extends a basic idealization of a stationary system used by

Jenike (1961) to the stability of a laterally confined rigid block

inclining on a stiff bedding plane. The following similar

assumptions were adopted in the present study with an

additional consideration of interface resistance: (a) the

resistance supporting the arch is characterized by unconfined

compressive strength, and (b) the load breaking the arch is due

to its own weight and to the force exerted by the material above

the arch. The mechanism involved and its implication on

instability can be explained in that if the load induced by weight

of the arch is greater than the unconfined compressive strength

and the interface resistance, the arch will collapse and therefore

the widest possible span or the failure width of block

B

f

of a

stable arch can be predicted.

The authors (Khosravi 2012) have recently developed

equations to describe the instability phenomena of undercut

slopes based on Jenike’s (1961) theory of cohesive arching in

hoppers, as shown in Eq.(1) which can be alternatively

expressed by Eq.(2) in terms of the inclined angle at failure

f

for a given span of undercut

B

.

sin tan cos

c

f

i

i

k

B

c T

(1)

1

sin

cos

i

c

f

i

c k

T B

i

(2)

where

α

: inclined angle,

T

: thickness of block,

i

: interface

friction angle,

c

i

: interface adhesion,

c

: unconfined

compressive strength,

: bulk unit weight,

: friction angle of

material,

k

: arching coefficients:

k

=0

no arching

k

1

=cos

strip arch with soil slip

k

2

=1

segmented arch with stable scarp

k

3

=4/π

circular arch with slope buckling

The arching effect is the ability of soil to transfer load