960

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

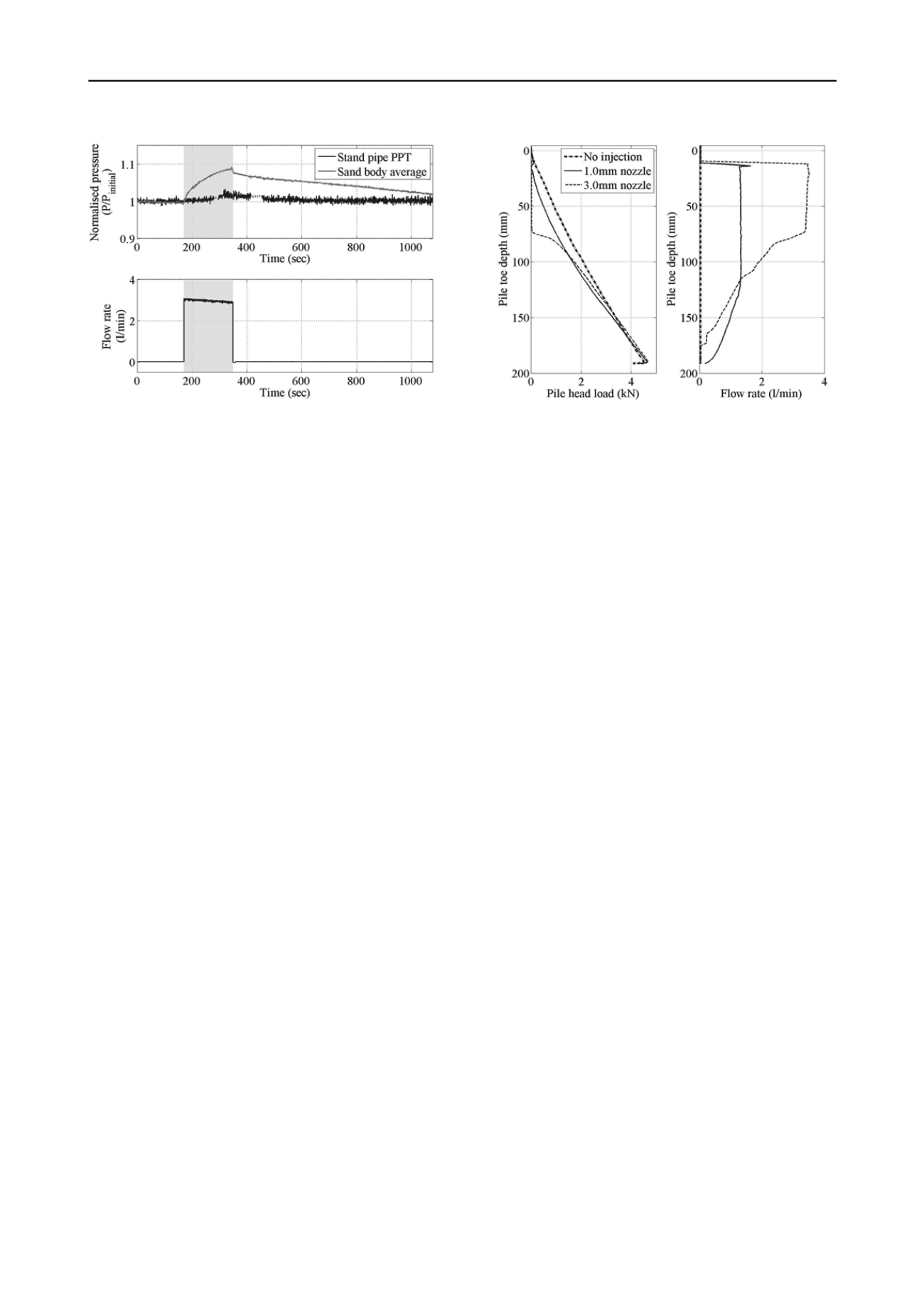

Figure 5. Illustration of a water injection event and subsequent model

drainage. Water is added to the model at around 3 litres per minute for

nearly 200 seconds (highlighted by the shaded region). This causes the

sand body to fill with water, represented by the increase in the

normalised pressure. Meanwhile, the stand pipe water level remains

constant and the pressure unchanged. (A dotted line represents a brief

period where the instrument failed.)

During an injection event, a small difference is evident in the

system. This is indicated by the increase in the sand body water

pressure during the injection phase. A small pressure difference

between the sand body and the standpipe arises, driving water

flow into the standpipe. Any additional water in the standpipe

drains away through the drainage holes at the top of the

standpipe.

The base pressure of the standpipe remains constant

throughout the process, showing that the standpipe maintains a

constant water height, as designed. With time, the pressure

difference between the standpipe and the sand body reduces.

This will slow the rate of drainage through the standpipe, until

the pressures become equal and no excess water is present in the

model after a time greater than 1100 seconds.

4.3 Installation load results

Multiple centrifuge tests were completed on identical sand

bodies. The sand bodies were tested for their continuity via a

control installation, without water injection. This was

effectively a penetration test and gave a reference to compare

the water injection aided installations to. There was good

agreement between the different control installations over the

multiple sand bodies used.

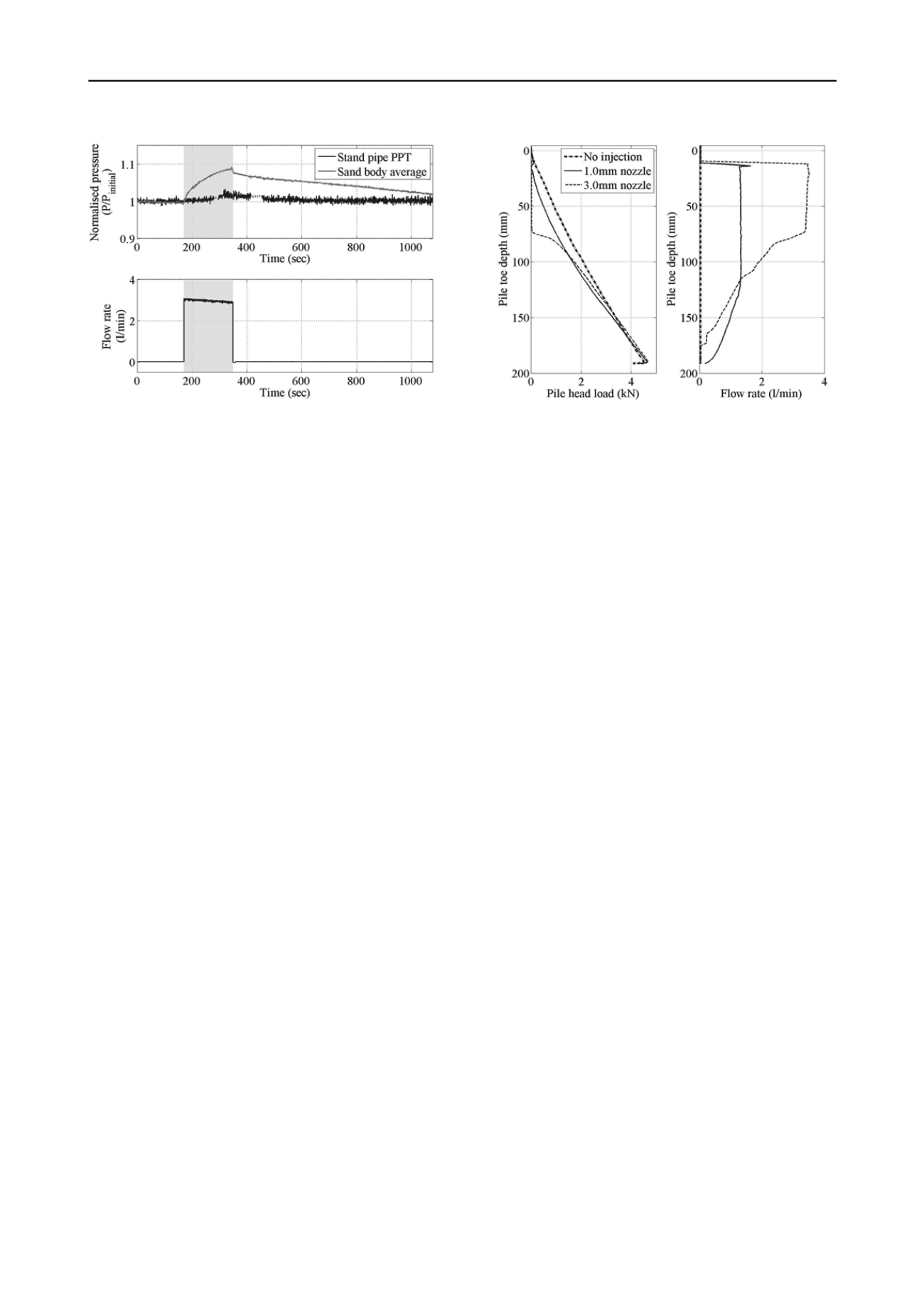

Figure 6 shows some installation data. The pile head loads

for three installations are shown – a control installation and two

water injection installations, one using a 1.0 mm diameter

nozzle and the other a 3.0 mm diameter nozzle. In addition, the

model flow rate is plotted, to show the link between the

delivered flow rate and reduction in load when compared to the

control installation.

Initially, load is generated in all installations as all piles are

installed to a depth of 2D

p

without the aid of water injection. At

this depth, the water supply to the pile is activated and the load

reduces to zero. The flow rate is allowed to stabilise at this

level as the pile installation continues.

The difference between the two nozzles is apparent, with the

smaller nozzle allowing a smaller peak flow rate to be pushed

through the pile. Despite a significant flow rate of 1.3 litres per

minute, there is little reduction in the pile load. The maximum

load reduction is experienced at the shallower depths, where the

load can be reduced to zero. Load reduction then diminishes

with depth as the pressure at the pile toe becomes closer to the

hydrostatic pressure in the sand body.

Figure 6. Comparison of effects of nozzles. Diameters 1.0 and 3.0 mm

nozzles are compared with the no injection installation. The flow rate

delivered to the pile is displayed for all installations in the right plot.

5 CONCLUSION

A water injection system has been successfully developed and

tested on the centrifuge at University of Cambridge. Peak

pressures of 1.2MPa and peak flow rates of 3.5 litres per minute

were delivered to the model pile. The system has been tested to

find the energy loss in the pipe line, with the aim of calculating

the toe pressure during an installation.

To maintain centrifuge balance during high flow rate events,

a standpipe system was developed and its performance closely

monitored. This proved successful for the duration of testing.

In addition, the system has been used to complete multiple

installations of water injection aided jacked piles. Different

nozzles were tested during the experimental program to

investigate their different effects. Whilst the effect of injection

reduces with depth, it was discovered that the larger nozzles

were the most effective at reducing installation loads.

6 ACKNOWLEDGEMENTS

The authors would like to thank Giken Seisakusho Ltd. for their

continued support throughout the duration of the research.

7 REFERENCES

Gaudin C., Bienen B. and Cassidy M.J., 2011. Investigation of the

potential of bottom water jetting to ease spudcan extraction in soft

clay.

Geotechnique

, 61(12) 1043-1054.

Goh T., Shiomi T., Yamamoto M., Ikeda T. and Motoyama M. 2004. A

solution for road construction. In

6th Malaysian road conference

,

Kuala Lumpur.

Goforth G.F., Townsend F.C. and Bloomquist D. 1991. Saturated and

unsaturated fluid flow in a centrifuge. In

Centrifuge in soil

mechanics

, 497-502, Ko and McLean.

Haigh S.K., Houghton N.E., Lam S.Y., Li Z. and Wallbridge P.J. 2010.

Development of a 2D servo-actuator for novel centrifuge

modelling. In

7th international conference on physical modelling

in geotechnics

, 239-244, Zurich.

Schneider J.A., Lehane B.M. and Gaudin C. 2008. Centrifuge

examination of pile jetting in sand. In

2nd IPA workshop

, 17-24

New Orleans.

Tomlinson M. and Woodward J. 2008.

Pile design and construction

.

Taylor & Francis, London

Tsinker G.P. 1988. Pile jetting.

Journal of geotechnical engineering

114(3), 326-334.

White D.J., Sidhu H.K., Finlay, T.C.R., Bolton M.D. and Nagayama T.

2000. The influence of plugging on driveability. In

8th

international conference of the deep foundations institute

, 299-310.

New York.